Impact atomization type temperature and pressure reducing valve

A technology of temperature reduction and pressure reduction, valve body, applied in the direction of balance valve, valve device, valve details, etc., can solve problems such as unstable operation, poor atomization effect, valve leakage, etc., to improve the effect of atomization and cooling, improve Atomization cooling effect, avoiding the effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

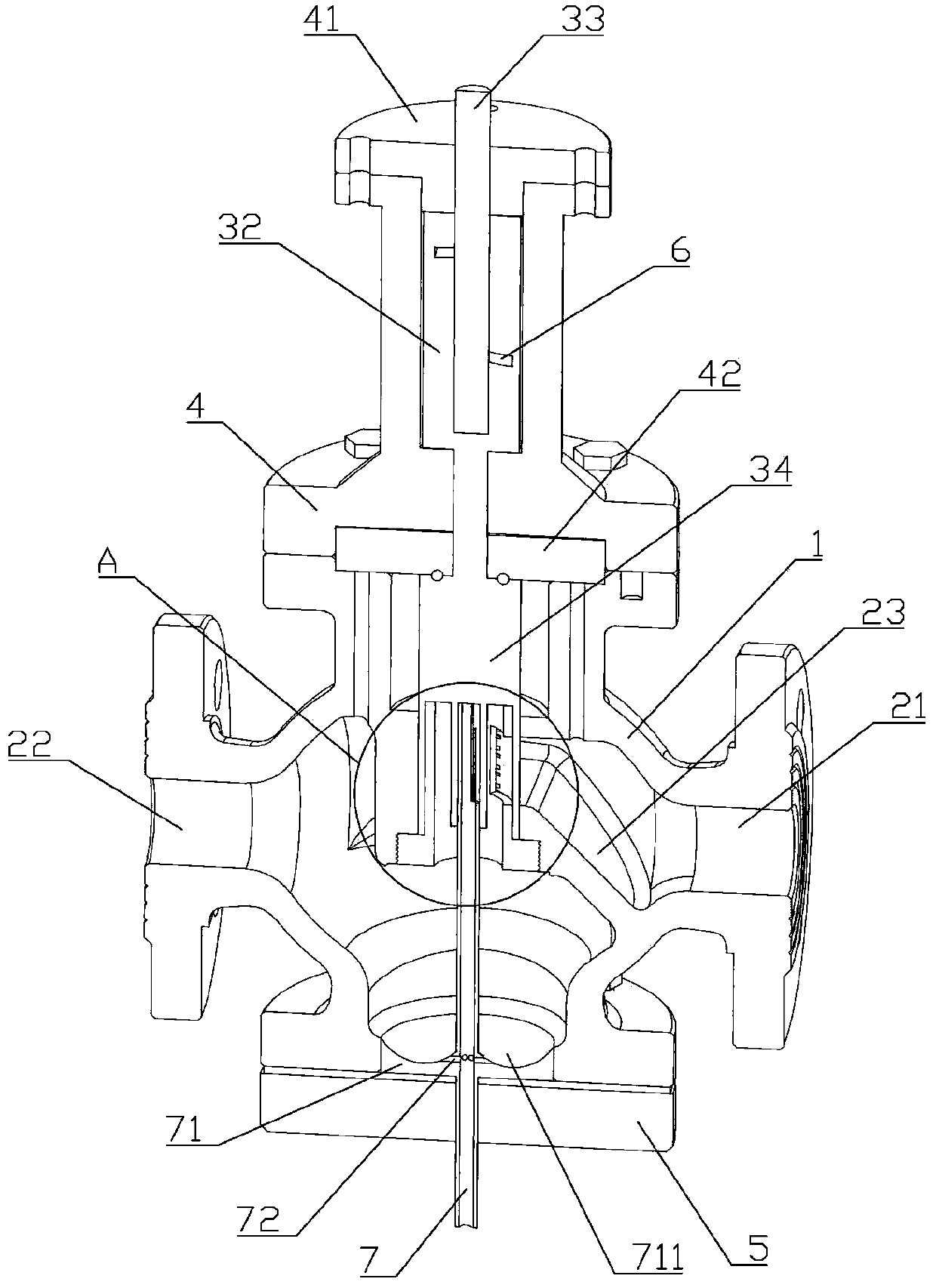

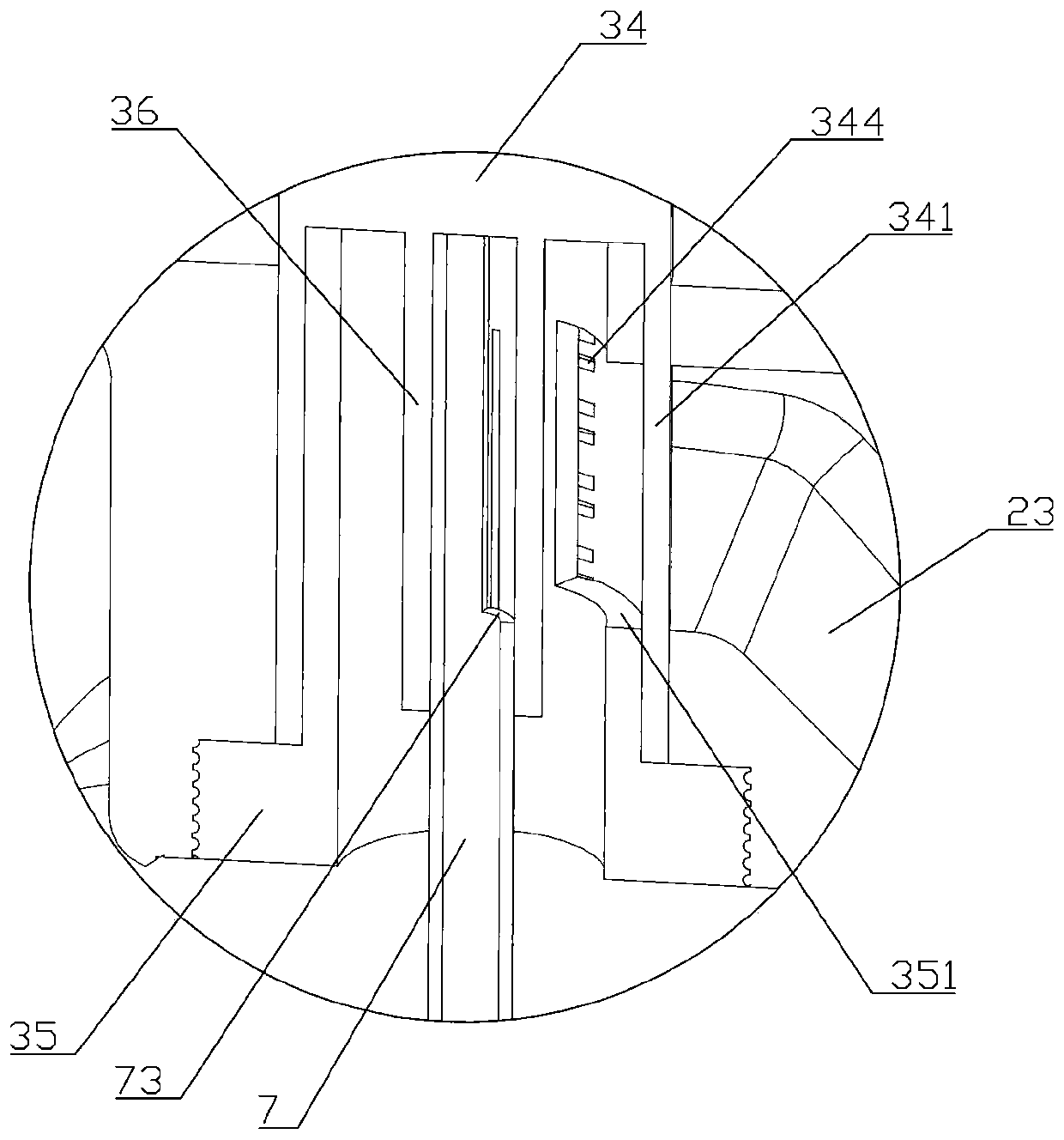

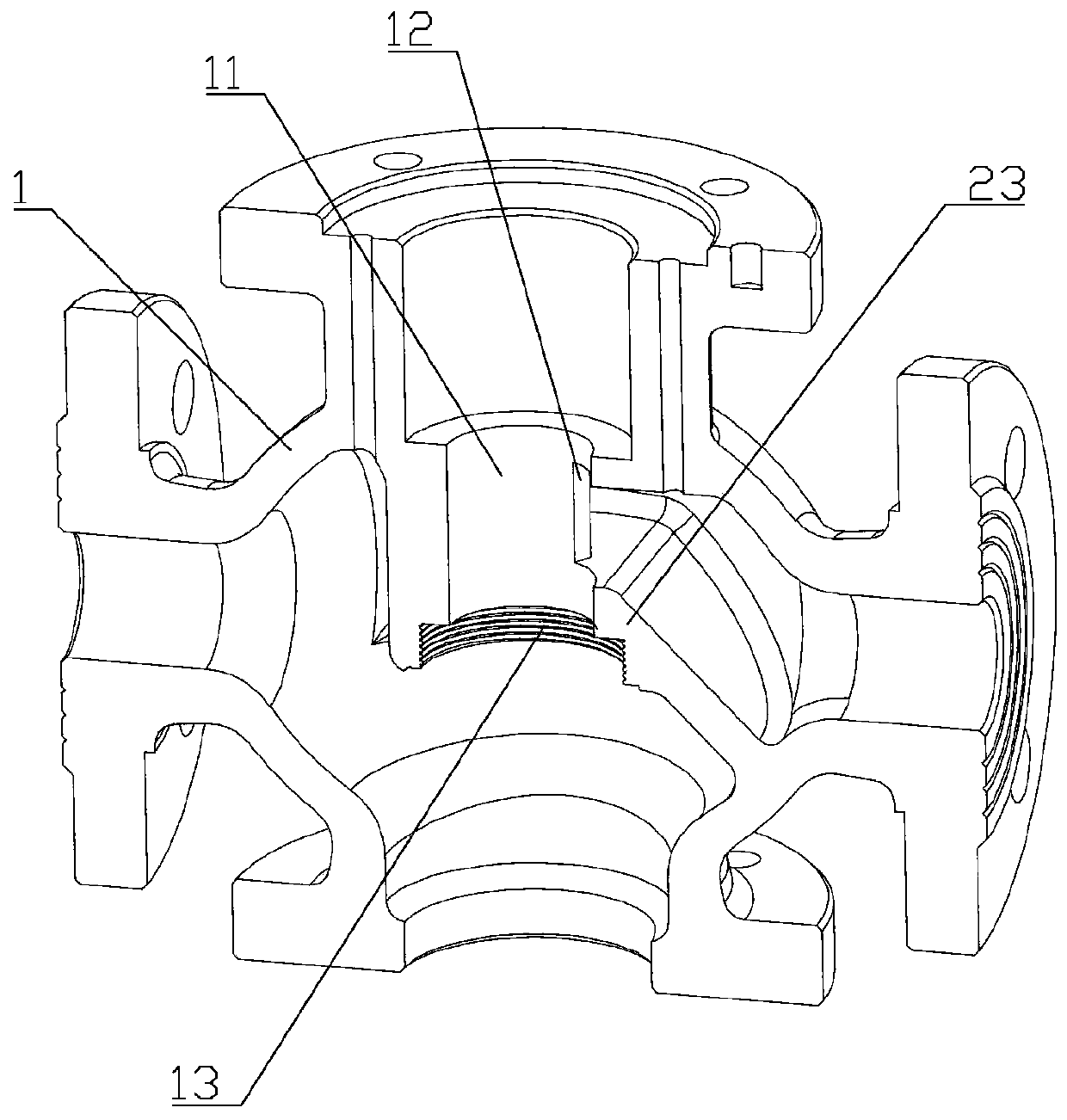

[0034] like Figure 1 to Figure 8As shown, an impact atomization type temperature and pressure reducing valve includes a valve body 1, a valve core 31 and a valve cover 4, the valve core 31 is installed in the valve body 1, the valve cover 4 is fixedly installed on the valve body 1, and the valve The cover 4 is equipped with an actuator, the valve body 1 is provided with an air inlet 21 and an exhaust port 22, the valve body 1 includes an upper valve chamber and a lower valve chamber, the upper valve chamber communicates with the air inlet 21, and the lower valve chamber The exhaust port 22 is connected, and an isolation layer 23 is arranged between the upper valve cavity and the lower valve cavity. A communication pipe 11 is installed on the isolation layer 23, and a first communication groove 12 is provided on the side wall of the communication pipe 11. The first communication groove 12 The range of the central angle of the arc is 90°~120°, the upper valve chamber and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com