Gasket retention system

一种保持系统、衬垫的技术,应用在衬垫领域,能够解决重新组装困难、系统不理想、耗时等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

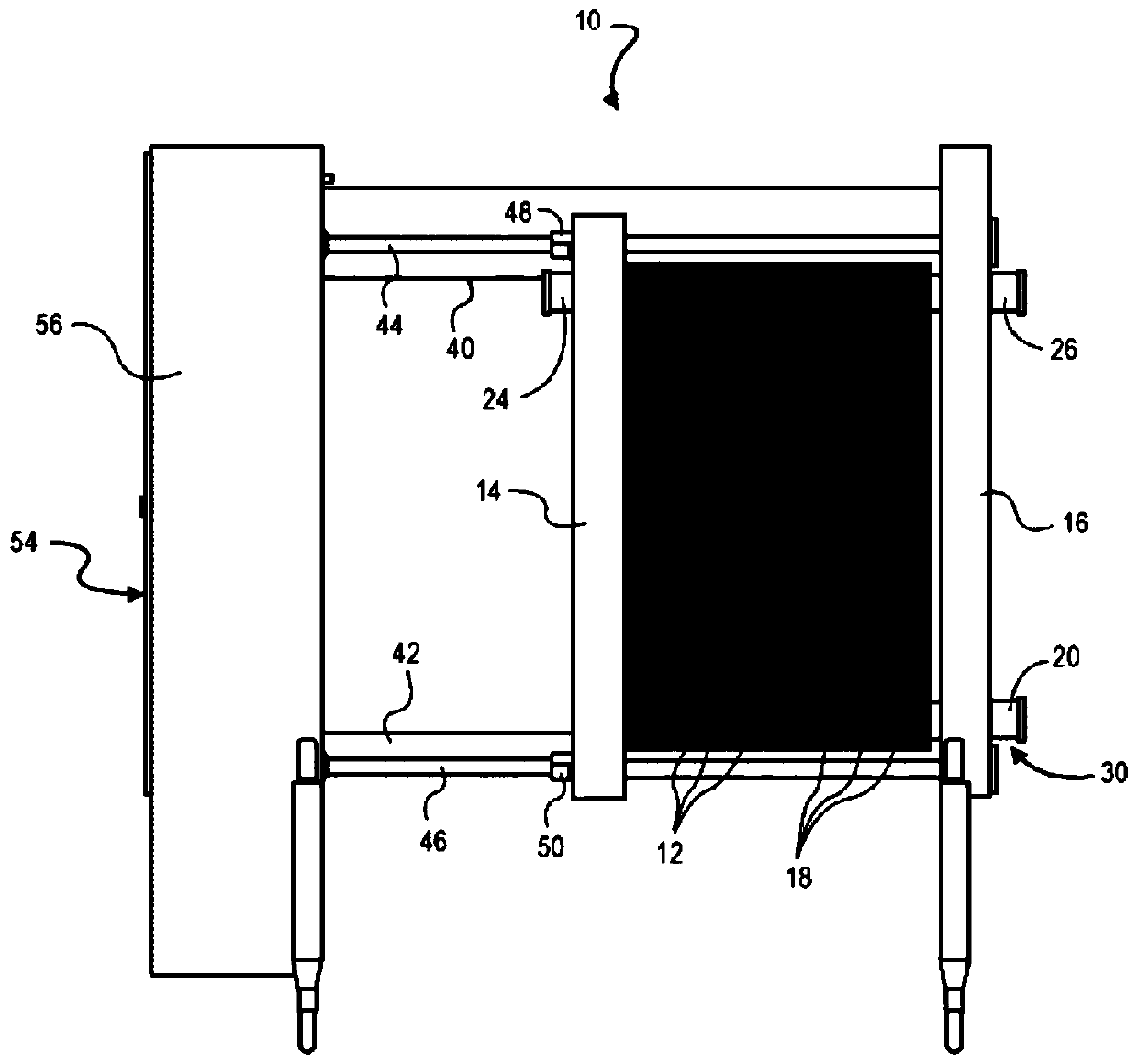

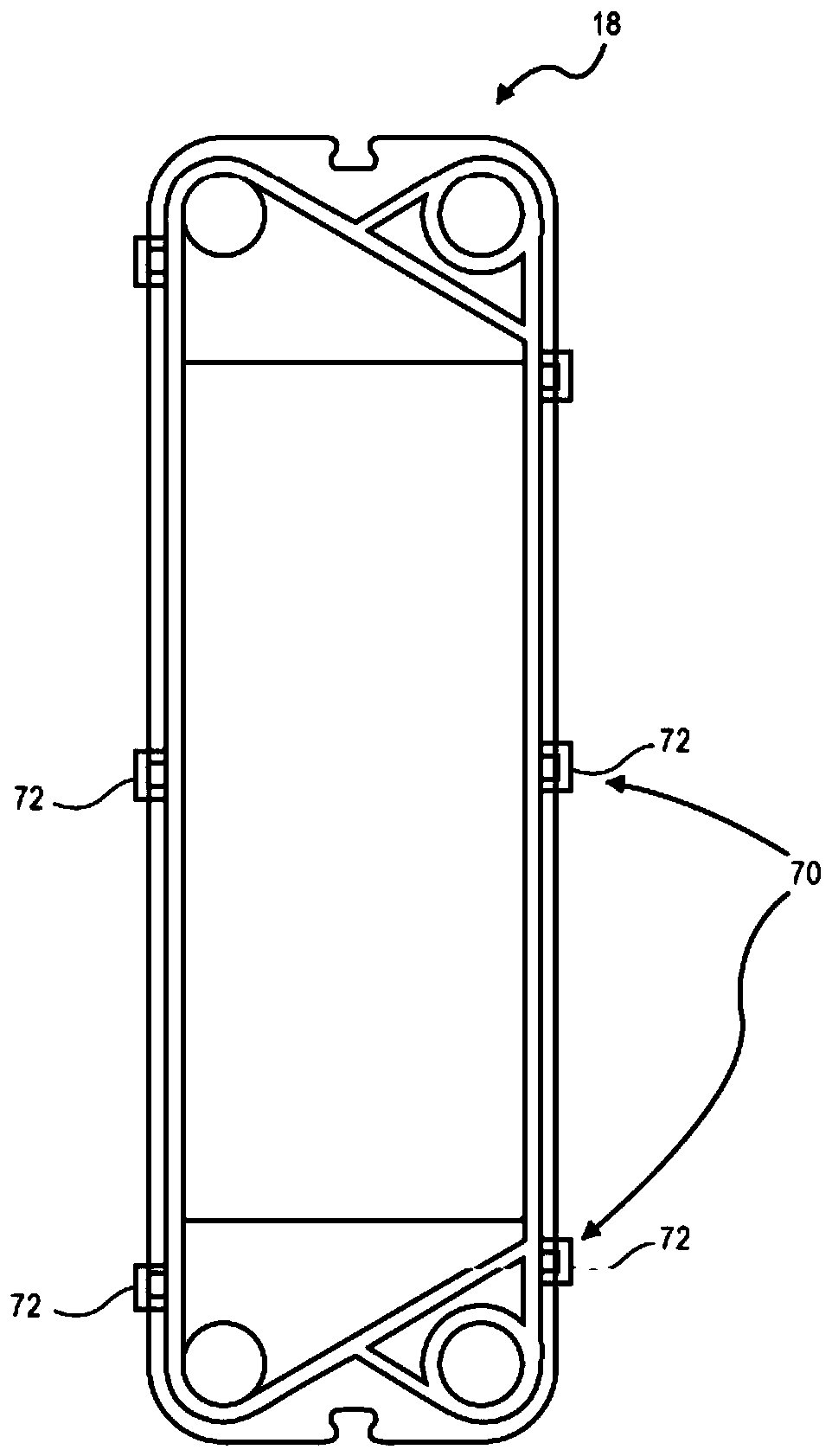

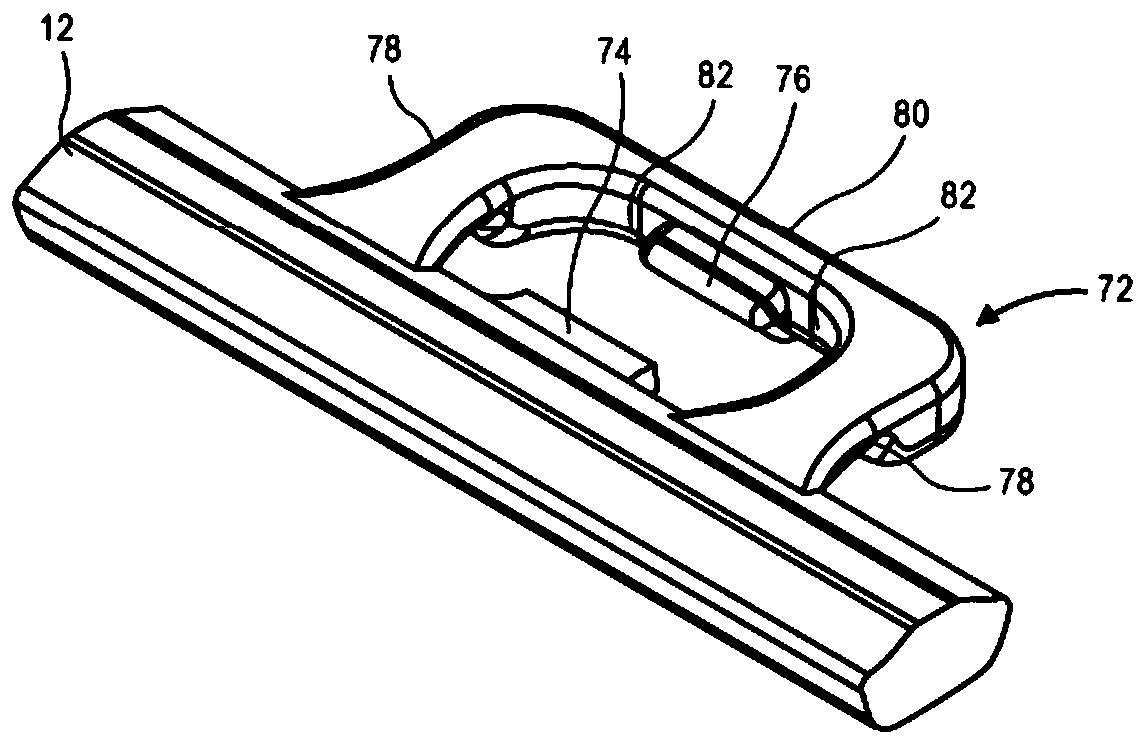

[0024] In the following, the present invention will be described in detail with reference to the accompanying drawings, in which the same reference numerals denote the same components throughout. Embodiments according to the present application propose an improved pad retention system which improves retention of the pad within the panel. In this way, the disassembly and reassembly of the plate stack in a plate heat exchanger is improved and resistant to degradation caused by exposure to chemicals, extreme temperatures, UV light, etc. This improved liner also provides excellent sealing characteristics and high resistance to material fatigue. Furthermore, due to the improved retention, labor costs are reduced by the improved gasket retention system and thus the slippage of the gasket from the plate is reduced during inspection, disassembly and reassembly of the plate heat exchanger.

[0025] figure 1 is a side view of a plate heat exchanger 10 suitable for use with gaskets an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com