Multistage centrifugal fan bearing removal device and method

A technology of bearing removal device and centrifugal fan, applied in hand-held tools, manufacturing tools, etc., can solve problems such as difficulty in bearing removal, achieve the effects of improving removal efficiency, saving manpower, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

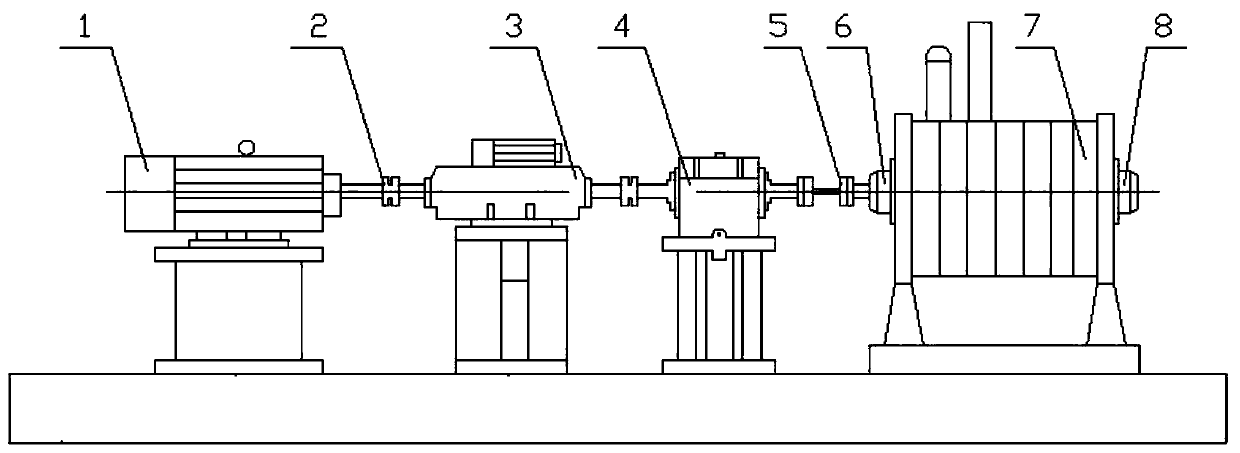

Embodiment 1

[0045] A bearing dismounting device, comprising a dismounting main body 100 and a lifting device 200, the dismounting main body 100 is connected to the output end of the lifting device 200; The two ends of 120 are respectively connected with the first dismounting device 130 and the second dismounting device 140; The second gear 141 in the second removal device 140 is meshed; the driving gear 121 rotates to drive the first gear 131 and the second gear 141 to rotate, the first gear 131 rotates to drive its output end to work, and the second gear 141 rotates to drive its output end work. The device includes a first dismounting device 130 and a second dismounting device 140. When dismounting the bearing, the output end of the first dismounting device 130 and the output end of the second dismounting device 140 are connected to the bolts on the bearing seat, and the user operates The prime mover 120 can quickly disassemble the bolts on the bearing, and then disassemble the bearing,...

Embodiment 2

[0057] The present invention also includes a dismounting method for the multistage centrifugal fan bearing, which requires the use of the dismounting device in Embodiment 1, and the method includes the following steps:

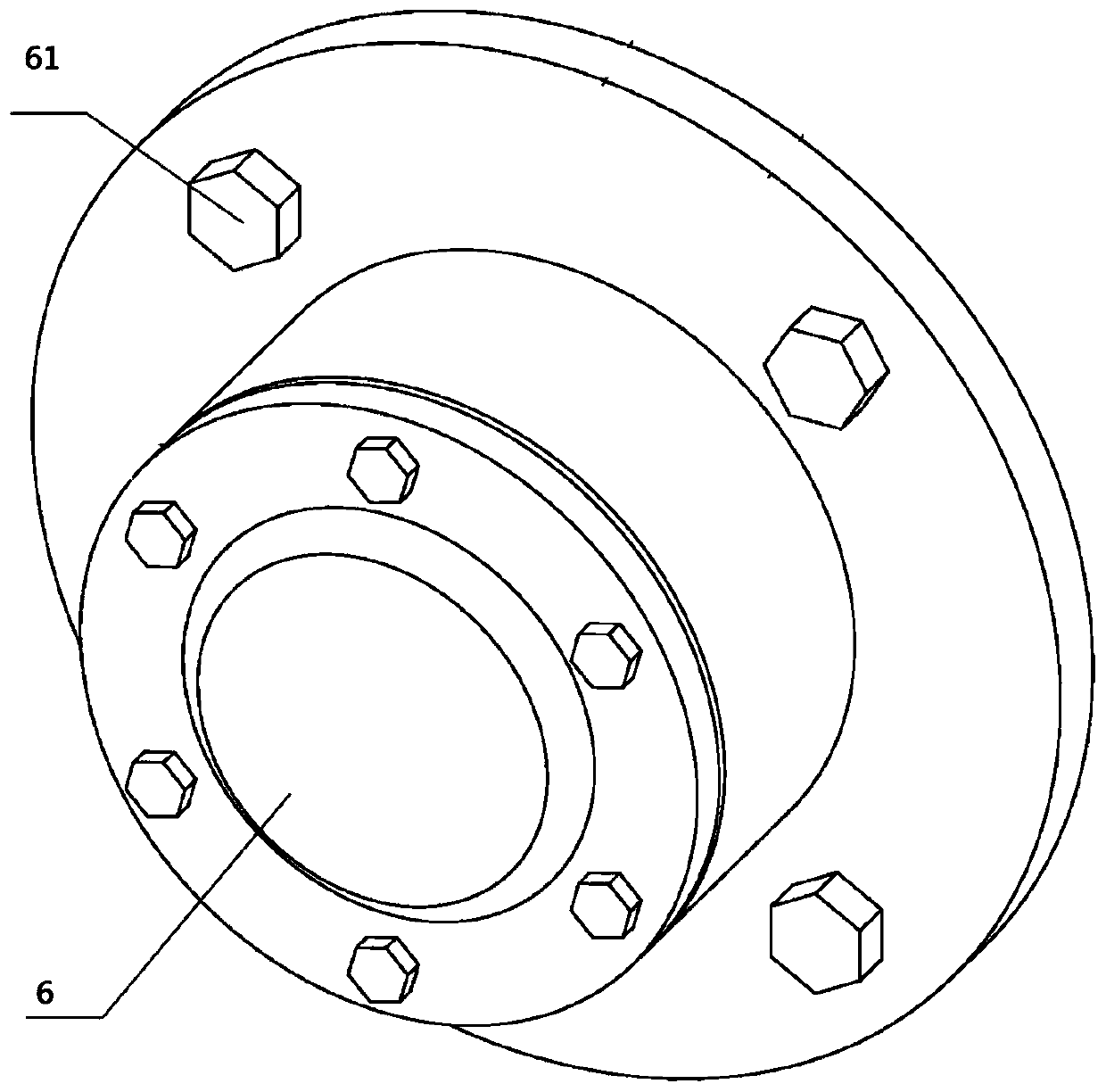

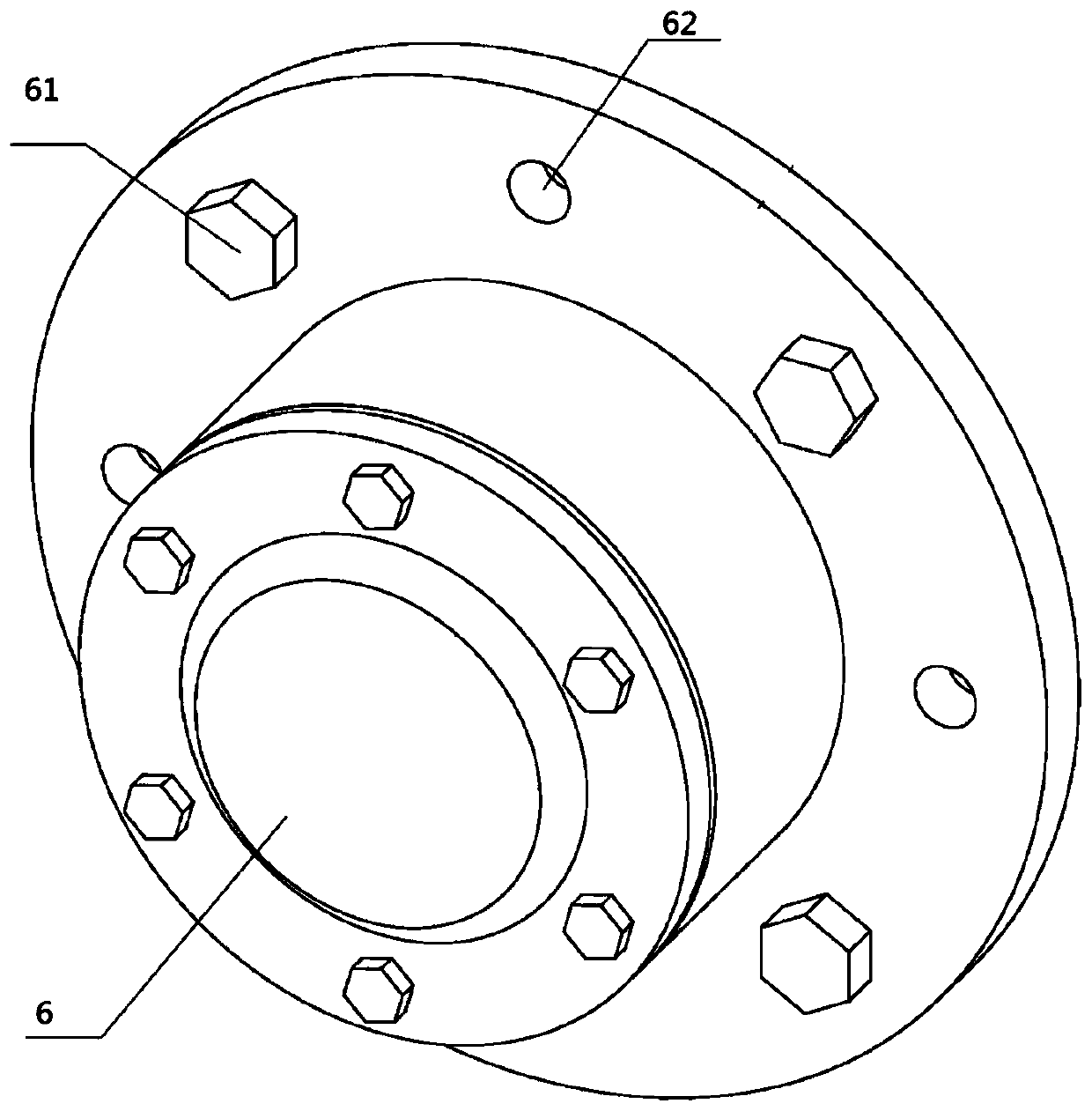

[0058] Step 1. On the front bearing seat 6, a screw hole 62 that runs through the front bearing seat is symmetrically provided, and a dismounting bolt is connected in the screw hole; screw hole, and a dismounting bolt is connected in the screw hole;

[0059] Step 2, disassemble the fastening bolts on the rear bearing seat 8, the removal of the fastening bolts specifically includes: the output end of the first dismounting device 130 and the output end of the second dismounting device 140 are connected with the fastening bolts on the rear bearing seat 8 To connect, the fastening bolts on the rear bearing seat are disassembled by the prime mover 120 . The output end of the first dismounting device 130 and the output end of the second dismounting device 140 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com