Improved mylar forming equipment and pneumatic unloading method thereof

A molding equipment and pneumatic unloading technology, which is applied in metal processing and other directions, can solve the problems of light leakage, low-reflection ink that damages the surface of the Mylar sheet, etc., achieve high stamping precision, improve product molding quality, and prevent lateral displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

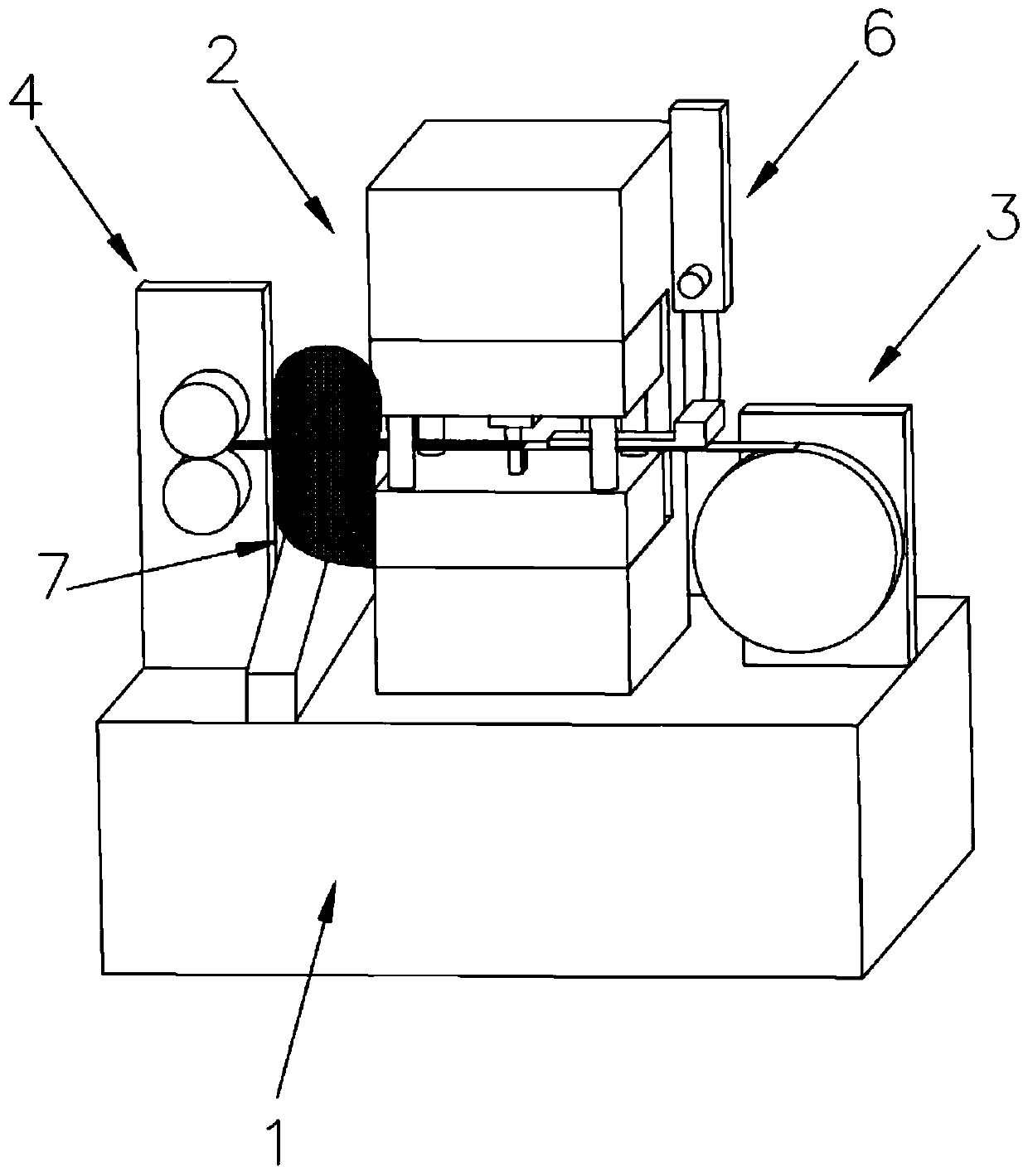

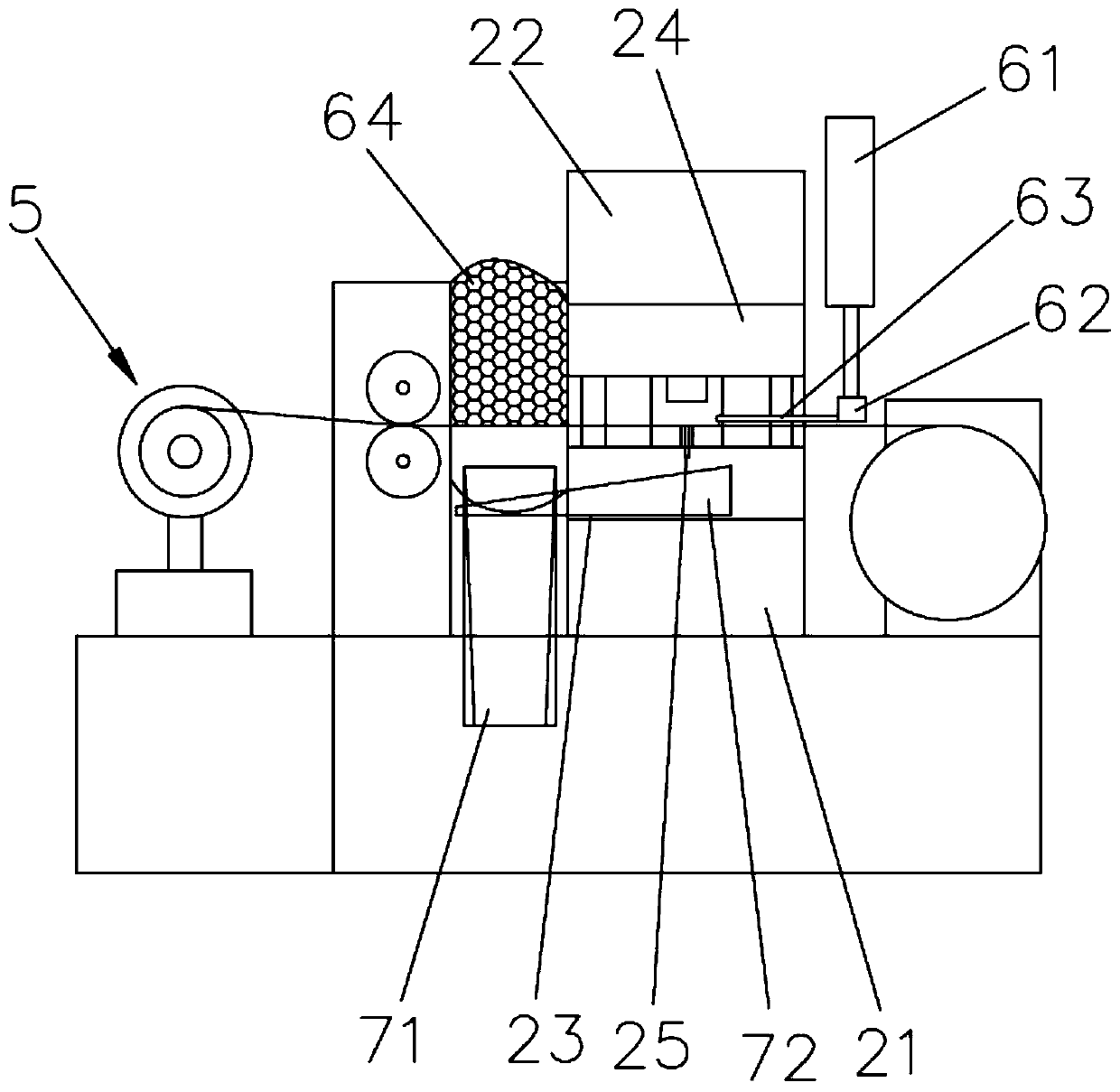

[0019] Attached below figure 1 to attach figure 2 The present invention will be described in detail.

[0020] An improved Mylar sheet forming equipment according to the present invention includes a base 1, a stamping device 2 arranged on the base 1, an unwinding device 3 is provided at the feeding end of the stamping device 2, and the stamping device 2 The discharge end of the pressure roller device 4 is provided with a pressure roller device 4, and the discharge end of the pressure roller device 4 is provided with a winding device 5, and the PET strip passes through the stamping device 2, the pressure roller device 4 and the winding device successively from the unwinding device 3 5. It also includes a pneumatic blowing and unloading device 6 for unloading the stamped Mylar sheet from the PET strip. The working principle of this equipment is that the PET material tape is rolled into the unwinding device 3, and then passes through the punching device 2, the pressing roller d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com