Construction method for penetrating through full-length prestressed tendon of segmental prefabricated assembled beam

A prestressed beam, prefabricated assembly technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of affecting the prestressed elongation value, low construction work efficiency, large construction resistance, etc., to reduce construction costs and improve. The effect of improving construction quality and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

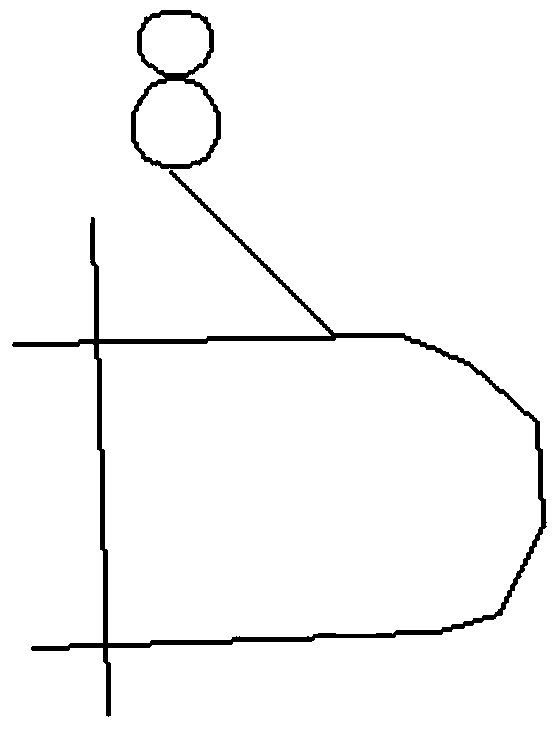

[0033] see Figure 1-10 A construction method for segmentally prefabricated assembled girder through-length prestressed beams shown includes the following steps:

[0034] (1) First cut a steel strand 1 that is about 3 meters longer than the designed full-length prestressed beam length (so that it is convenient to operate), the steel strand 1 is a single piece, and is used for trying on. An annulus 2 (the diameter of the annulus 2 is the same as the diameter of the steel strand bundle 3 to be worn) made of light round steel bars is fixed at the end of the steel strand 1 by electric welding;

[0035] (2) The operator holds the other end of the steel strand 1, that is, the end of the unwelded ring 2, and passes the steel strand 1 into one end of the prestressed tunnel to be penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com