Coiled tubing sand filling separate layer fracturing method

A technology of layered fracturing and tubing, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., and can solve problems such as packers and failures that are prone to occur, so as to avoid failure problems, convenient operation and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

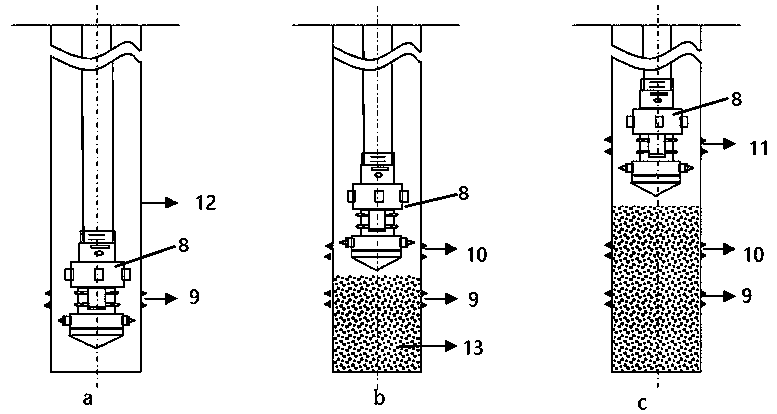

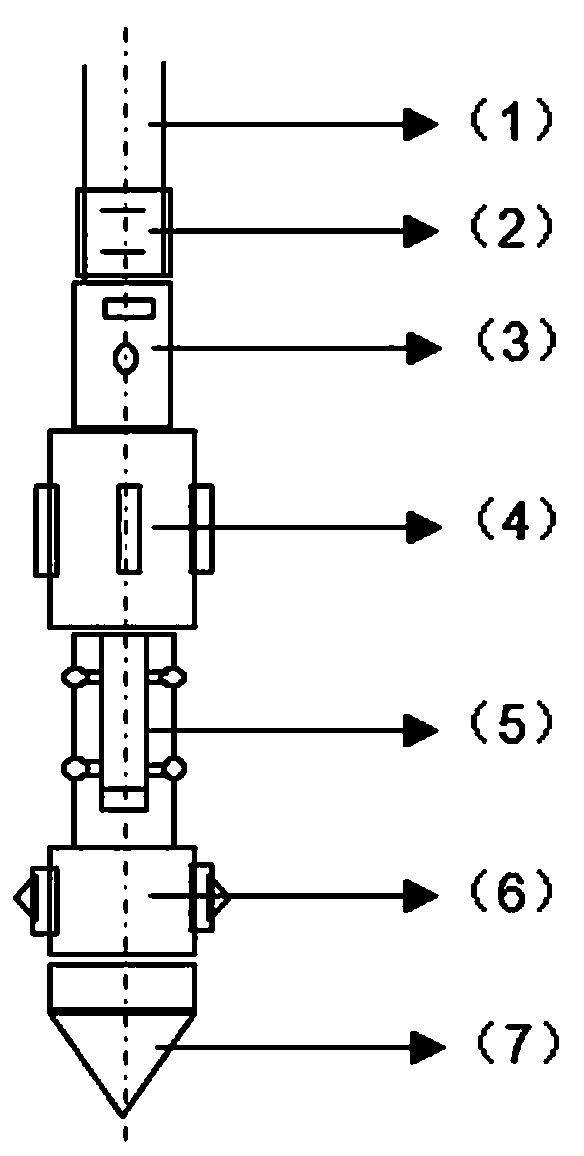

[0021] Embodiment 1: as attached Figures 1 to 2 As shown, the coiled tubing sand-packed layered fracturing method is carried out as follows: the first step is to determine the depth position of the perforation point: a fracturing tool string 8 is fixedly installed at the lower end of the coiled tubing 1, and the fracturing tool string 8 is formed by The connector 2, the motor head assembly 3, the centralizer 4, the injector 5, the positioner 6 and the guide shoe 7 are fixed and connected sequentially from top to bottom, and the fracturing tool string 8 is lowered to the determined perforation point depth position;

[0022] The second step, the first stage of perforation and fracturing: inject the sand-carrying fluid into the coiled tubing 1, and the sand-carrying fluid in the coiled tubing 1 passes through the injector 5 to blast and perforate the first layer of perforation. From the tubing 1 to the second-stage perforation point, the fracturing fluid and sand-carrying fluid...

Embodiment 2

[0033] Embodiment 2: As an optimization of the above embodiment, when the pressure test of the sand-packing section in the sand-packing layered fracturing process is unqualified, continue to fill or re-fill the sand until the pressure test requirements are met.

[0034] When the pressure test of the sand-packing section in the process of sand-packing layered fracturing fails, re-check the sand-packing volume, volume of the sand-packing section, and sand settlement time, and check the sand surface if necessary. If the sand surface does not reach the designed well depth, Continue sand filling. If the pressure test of the sand filling section is still unqualified, the sand filling and layering process can be carried out again.

Embodiment 3

[0035] Embodiment 3: As an optimization of the above embodiment, after the fracturing of all layers is completed, the fracturing tool string 8 under the coiled tubing 1 is replaced with a sand washing tool. The sand is filled and washed out of the wellbore. After the wellbore is cleaned, the coiled tubing 1 and the sand washing tool are put forward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com