Heating control method, device, medium and liquid heating container

A liquid heating container and heating control device technology, applied in the field of heating control methods, medium and liquid heating containers, and devices, can solve the problems of poor cooking effect, low heating power, long heating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

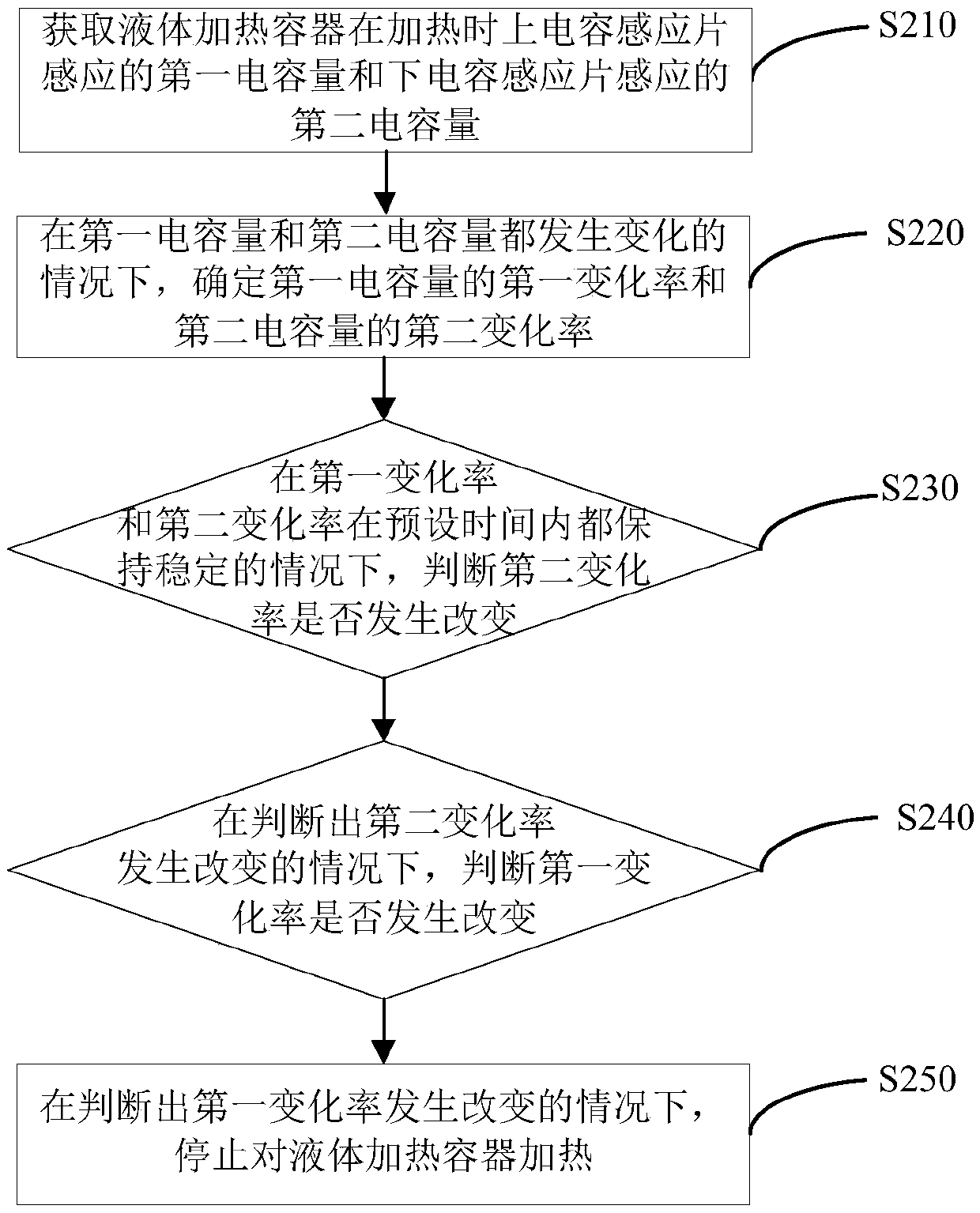

[0096] Further, based on the first embodiment of the heating control method for a liquid heating container of the present invention, in the second embodiment of the heating control method, judging whether the second change rate changes includes:

[0097] When the temperature of the liquid inside the liquid heating container is greater than the preset temperature, it is judged whether the second rate of change changes.

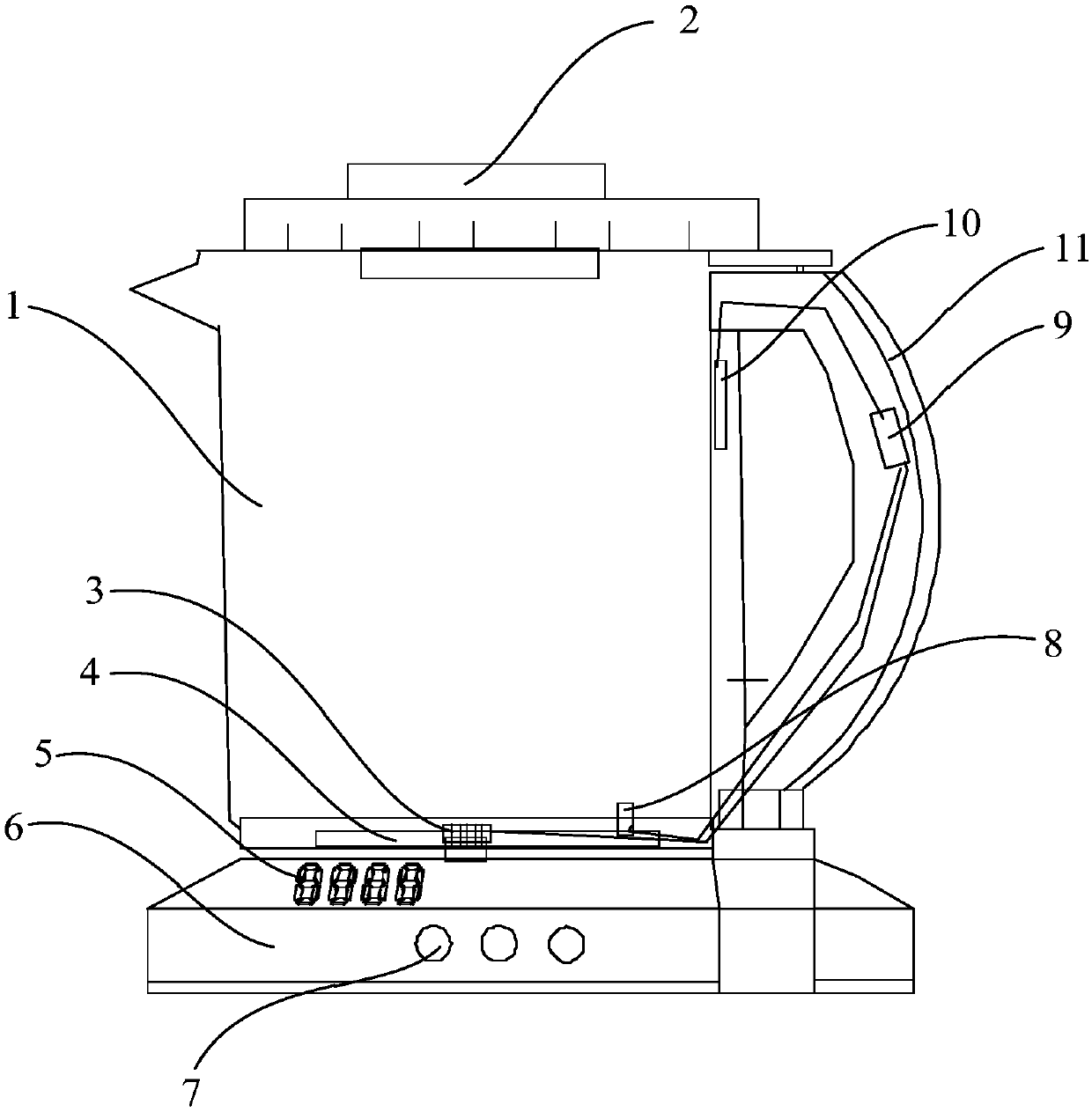

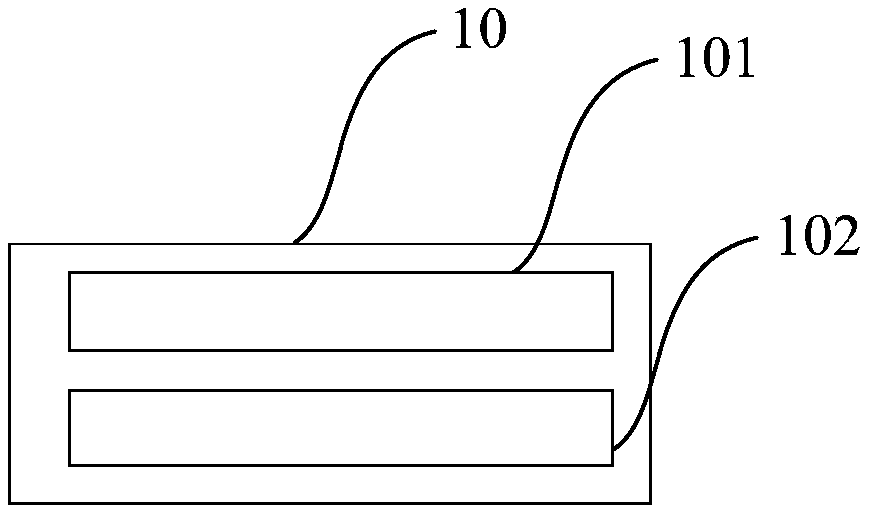

[0098] That is, on the basis of the first embodiment, in addition to obtaining the two capacitances sensed by the capacitive sensing sheet 10 when the liquid heating container is heated, the temperature of the liquid inside the kettle body 1 during heating is also obtained simultaneously. In this example, if figure 1 As shown, in order to obtain the temperature signal, the health pot can further include a temperature sensor 8 arranged at the bottom of the body 1 to detect the temperature of the liquid such as water inside the body 1, and the temperature signal ...

no. 1 example

[0099] Further, based on the first embodiment of the heating control method for the liquid heating container of the present invention, in the third embodiment of the heating control method, it also includes:

[0100] When it is determined that the second rate of change has changed, the heating power to the liquid heating container is reduced.

[0101] From the analysis in the first embodiment, it can be seen that before the second change rate Vc2 changes, the liquid heating container has not yet produced foam or the foam has not risen, so at this time, the power to the liquid heating container can be increased, that is, with a constant maximum The power is used to heat the liquid heating container; and when the second change rate Vc2 changes, the surface foam starts to rise. If the original high power is maintained at this time, the foam will rise too fast and there is a risk of overflow. Therefore, it is necessary to reduce the power at this time , For example, intermittent h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com