System and method for handling reel of pipe

A technology of pipe reel and reel, applied in the field of reel system, can solve problems involving extra equipment and manpower, large pipe reel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

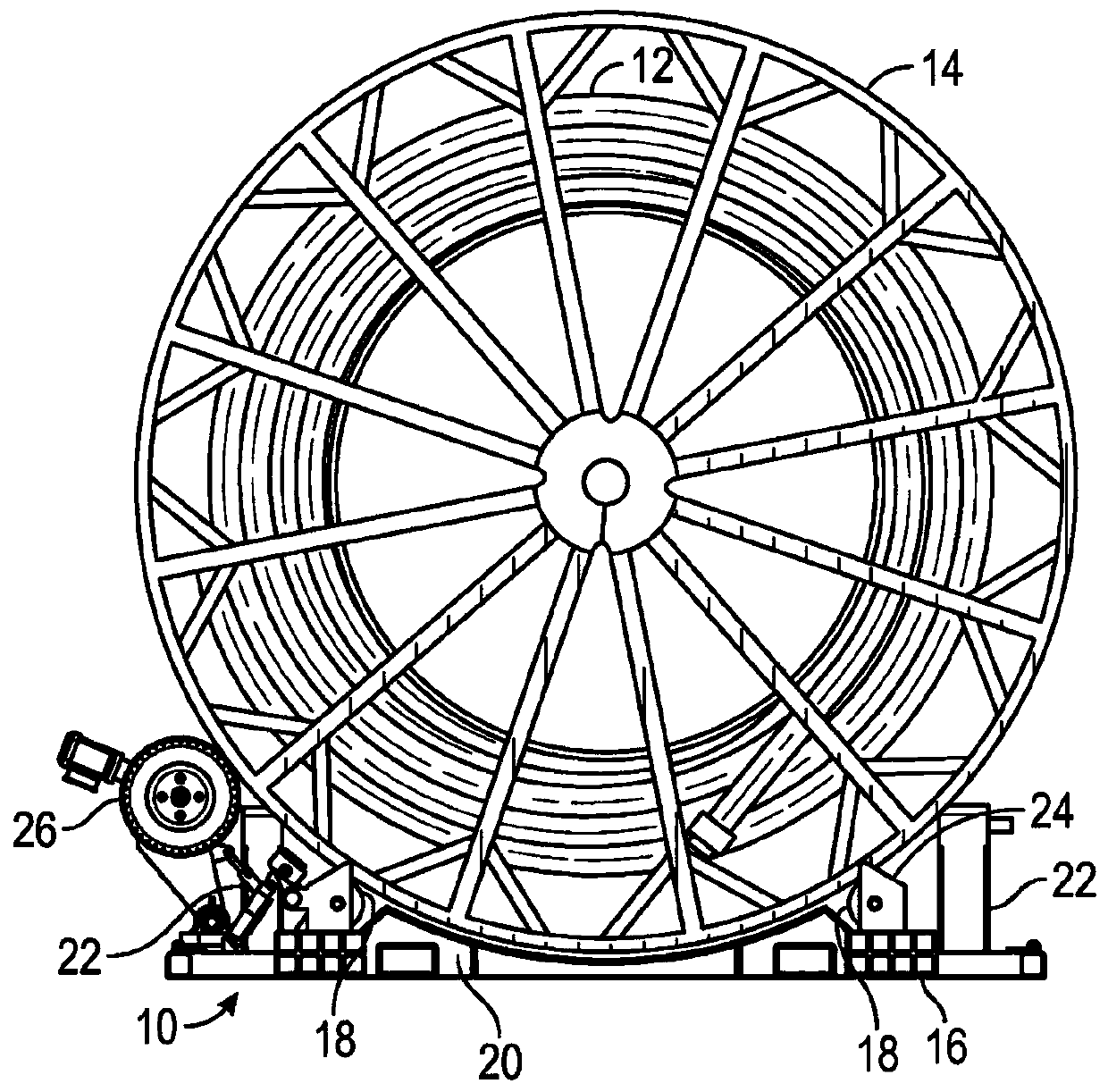

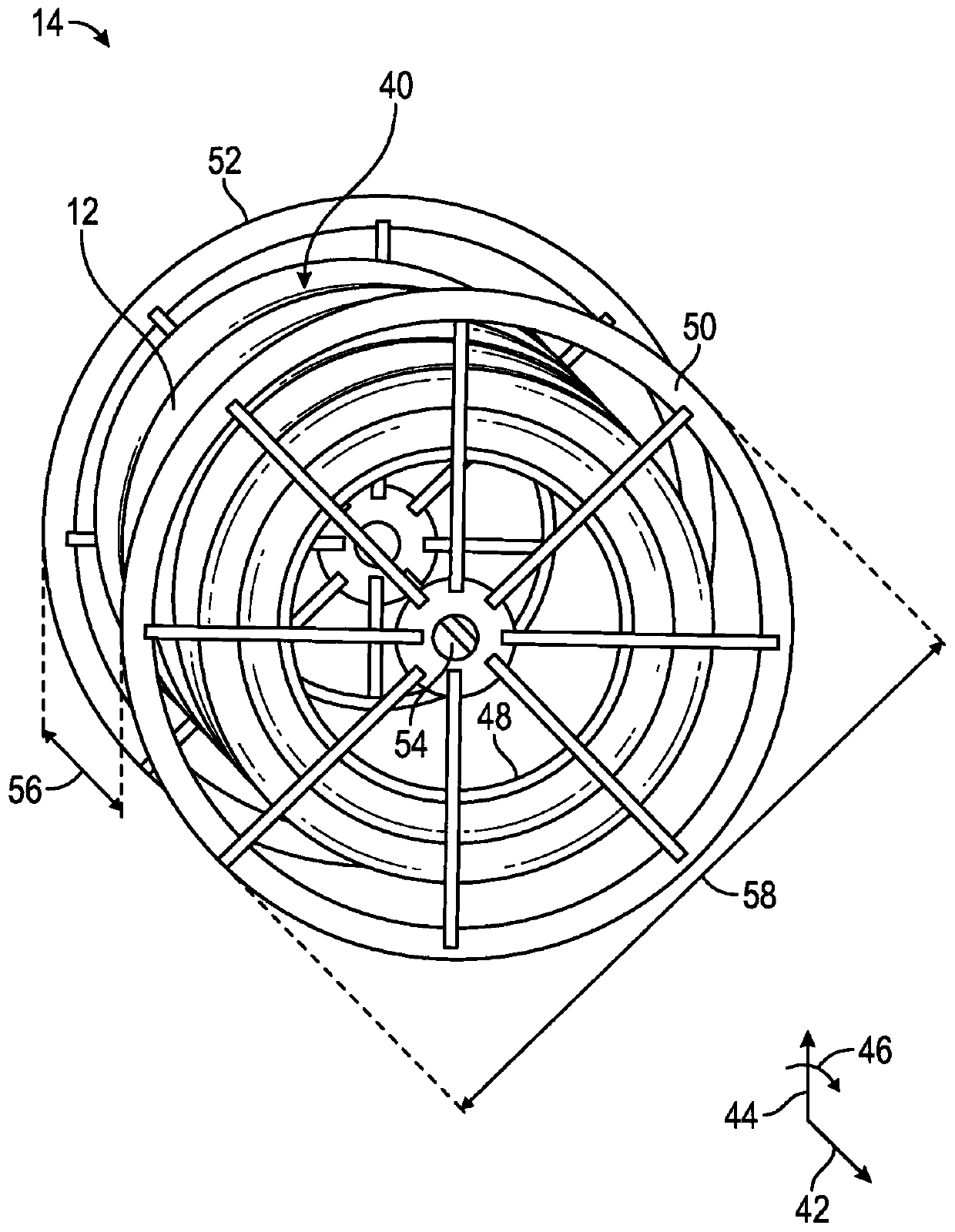

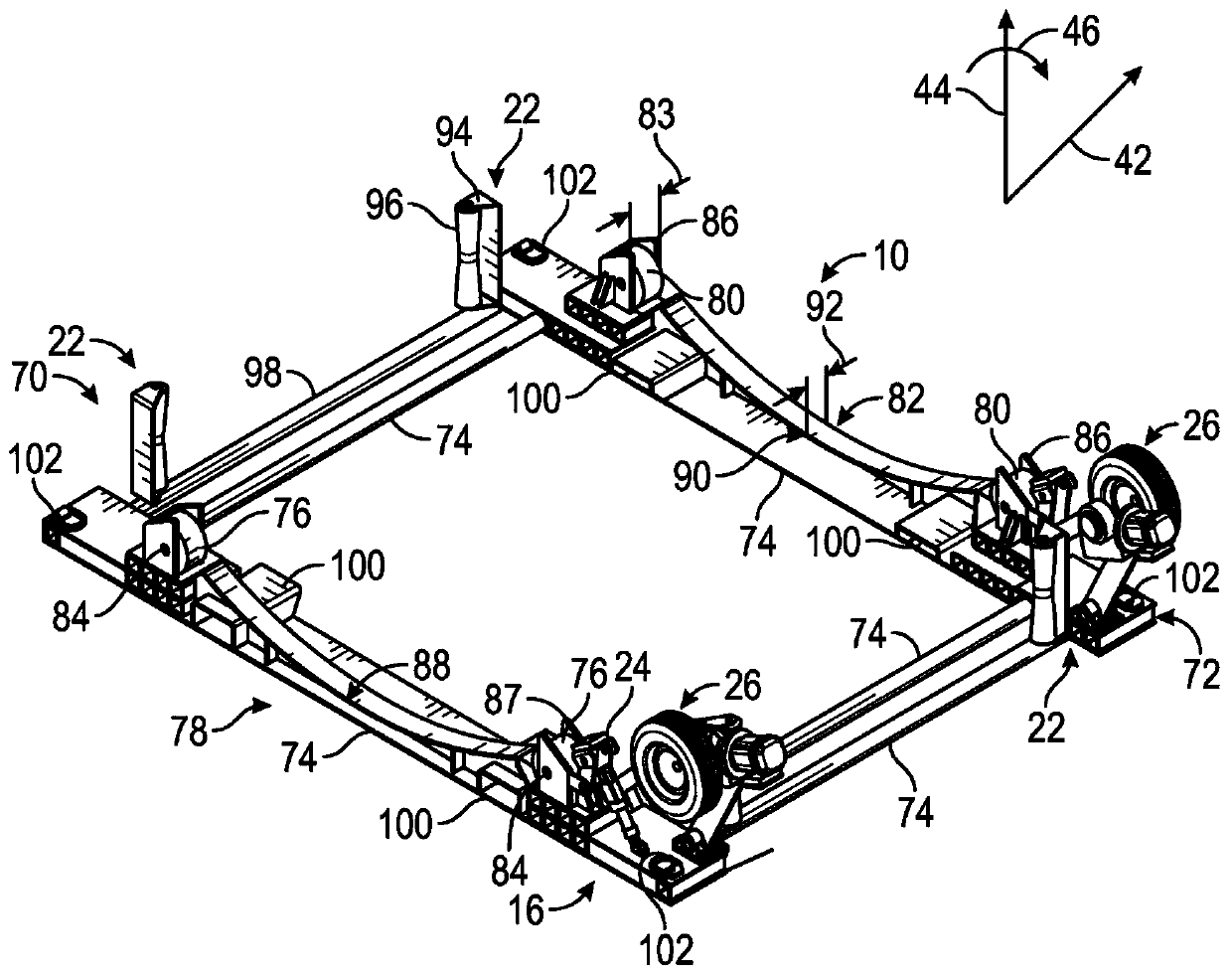

[0021] Embodiments of the present disclosure generally relate to a system for unrolling a spool of flexible pipe. A tube reel bracket according to embodiments of the present disclosure may include a frame, rollers, brackets, tube guides, tube brakes, and tube rewinders.

[0022] Embodiments of the present disclosure will be described below with reference to the drawings. In one aspect, embodiments disclosed herein relate to embodiments for unrolling a spoolable tube using a tube reel carriage.

[0023] As used herein, the term "coupled" or "coupled to" may indicate establishing a direct or indirect connection, and is not limited to either, unless explicitly so referenced. The term "group" may refer to one or more items. Wherever possible, similar or identical reference numbers are used in the drawings to identify common or identical elements. The drawings are not necessarily to scale and certain features and certain views of the drawings may be shown exaggerated for clarity...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap