Polyol polyester and polyhydroxy alkane blends with polar polymers

A technology of polar polymers and branched hydroxyalkanes, which can be used in building components, transportation and packaging, chemical instruments and methods, etc., and can solve the problems of reducing the quality of the surface material layer and being volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

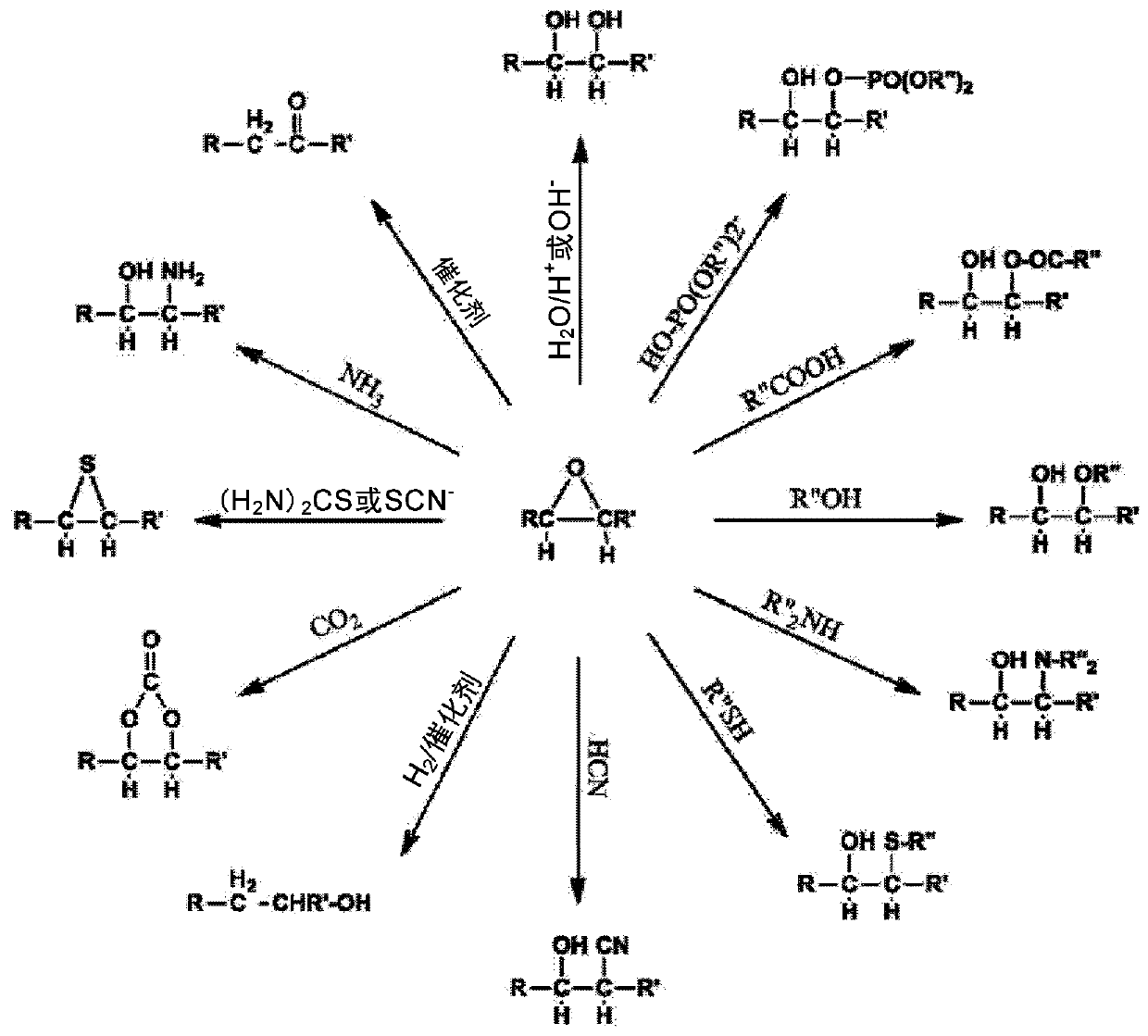

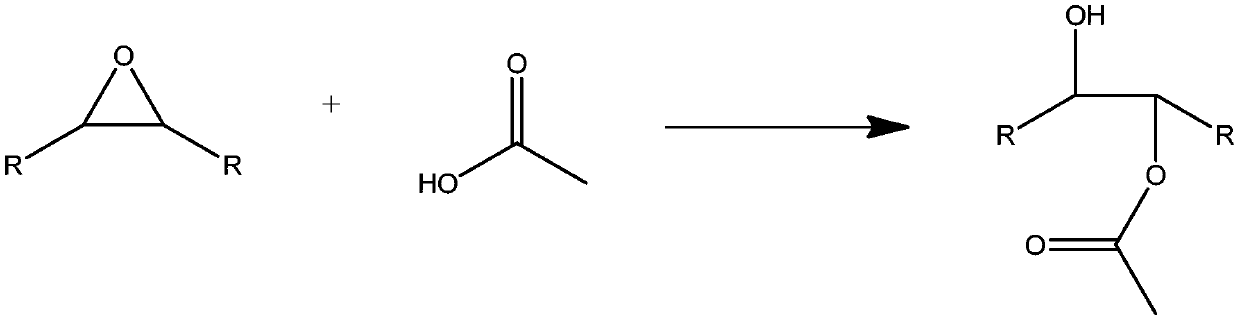

Method used

Image

Examples

Embodiment 1

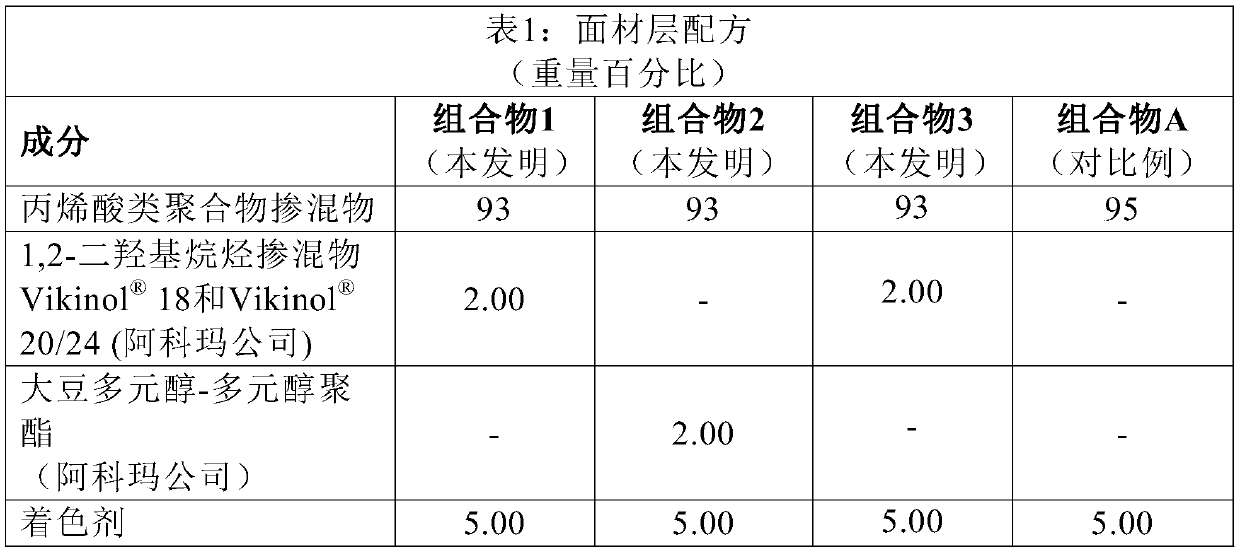

[0136] Example 1: Surface Layer Blend:

[0137] The following facesheet polymer blends were prepared, each blend containing a different gloss improving additive in accordance with the present invention. A comparative polymer blend without the gloss improving additive was also prepared.

[0138] These facestock formulations are shown in Table 1.

[0139]

[0140] These acrylic blend cap layer formulations were melted by melting the components shown in Table 1 above in a twin screw extruder operating at 300-425 revolutions per minute (RPM) and using the extruder temperature profile shown in Table 2. Blend to prepare.

[0141]

Embodiment 2

[0142] Example 2: Composite Structure :

[0143] The acrylic lidding stock blend prepared according to Example 1 was coextruded on a PVC substrate using a custom 1"x4" die and two extruders: a substrate layer extruder and a facestock layer extrusion machine.

[0144] The PVC substrate extruder was a single screw extruder operating at 9 revolutions per minute (RPM) and had a barrel temperature profile of 168°C (feed end) to 182°C (die end).

[0145] The acrylic blend facestock layer extruder was a single screw extruder and had a barrel temperature profile of 170°C (feed) to 210°C (die end). The coextrusion die temperature for the profiles was set at 165°C to 200°C.

[0146] For each facestock composition prepared according to Example 1, gloss and impact measurements were performed on final profiles prepared at 165°C and 200°C die temperatures.

[0147] The results are shown in Table 3 below, the facestock layer thickness was 0.006" to 0.007", and the total part thickness w...

Embodiment 3

[0150] Example 3: Decomposition Temperature of Blends Containing Gloss Improvement Additives

[0151] The thermal decomposition temperature is a convenient method of determining the thermal operating window for plastic extrusion because it provides a guide to the temperature at which extrusion can occur before it begins to degrade.

[0152] The thermal decomposition temperatures of facestock layer blend Composition 1 and Composition A prepared according to Example 1 were measured and compared. The results are shown in Table 4 below.

[0153]

[0154] From these results it is clear that the addition of polyol polyester increases the decomposition temperature of the acrylic face stock by about 10°C. As noted above, this effect also serves to broaden the processing temperature range of these materials so that improved gloss can be obtained by extruding at higher temperatures without degrading the polymer. It is also important that, as expected, the addition of polyol does ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com