Equivalent slitting machine with automatic pushing function

A technology of equal slitting and function, which is applied in metal processing, food processing, application, etc. It can solve the problems of cleaning, poor function of slitting machine, and inability to slitting sugarcane in equal amounts, and achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

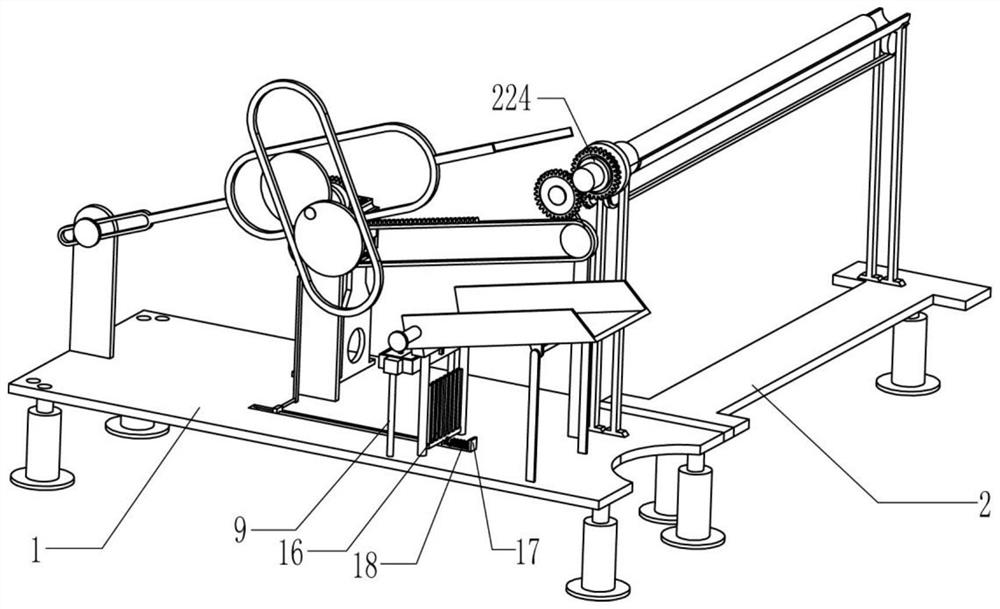

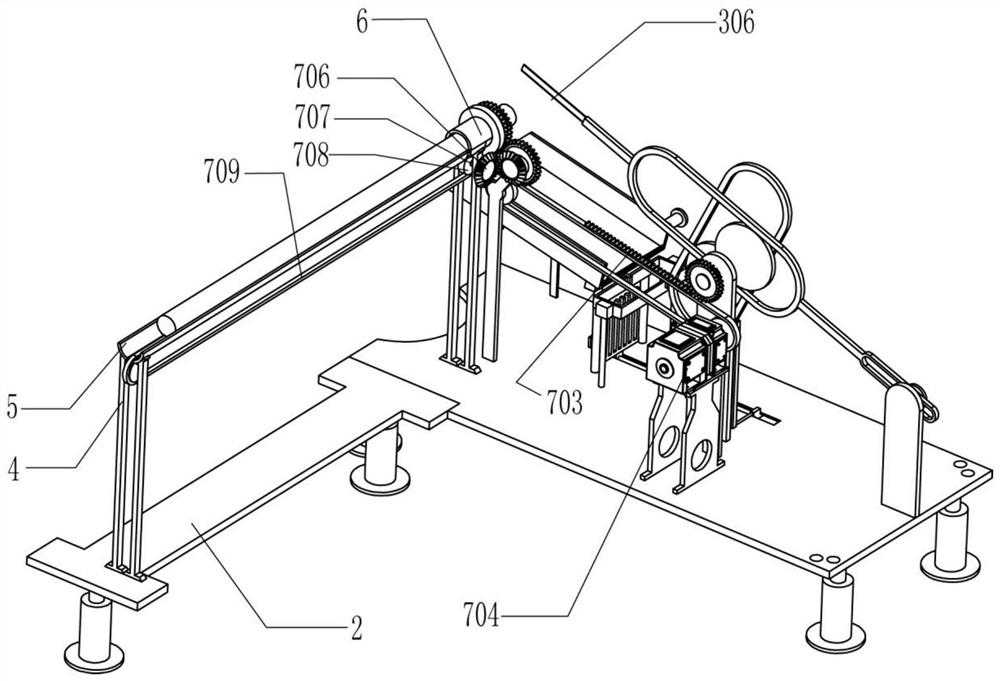

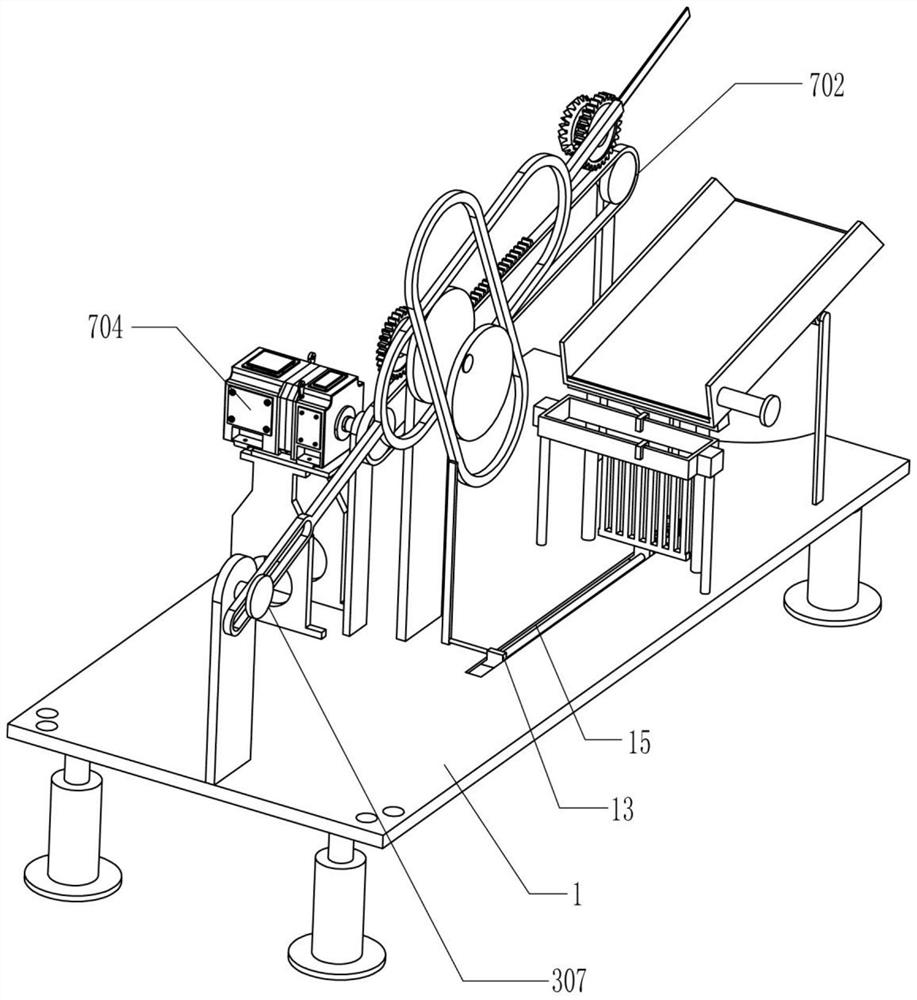

[0023] An equal slitting machine with automatic material pushing function, such as Figure 1-6 As shown, it includes a first base 1, a second base 2, a swing cutting device 3, a support rod 4, an arc-shaped guide plate 5, a limit arc-shaped plate 6, an intermittent transmission device 7, a mounting frame 8, a support base 9, The receiving hopper 10 and the limit frame 11, the swing cutting device 3 for equally cutting sugarcane is installed on the upper side of the first base 1, and one of the support rods is fixedly installed on the upper side of the first base 1 4. Another support rod 4 is fixedly installed on the upper side of the second base 2, the arc-shaped guide plate 5 is fixedly installed on the upper ends of the two support rods 4 and the bottom of the arc-shaped guide plate 5 is provided with a long guide hole, The arc-shaped guide plate 5 is used to place the sugarcane that needs to be cut. The limit arc-shaped plate 6 is fixedly installed on the upper side of one ...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 , image 3 and Figure 6 As shown, it also includes a slide block 13, a push rod 14, a connecting rod 15, a shaking plate 16, a riser 17 and a compression spring 18. The upper side of the first base 1 is provided with a chute 12, and the chute 12 The slide block 13 that can move left and right is installed in the sliding type, and the push rod 14 is fixedly installed on the slide block 13 and the upper end of the push rod 14 is in contact with the second eccentric frame 305, and the push rod 14 is used for the second eccentric Driven by the frame 305, the slider 13 is driven to move left and right, the connecting rod 15 is fixedly installed on the slider 13 and the connecting rod 15 is slidably positioned in the chute 12, and the shaking plate 16 is fixedly installed on one end of the connecting rod 15, And the shaking plate 16 is close to the limit frame 11, the shaking plate 16 is used to beat the storage bag for collectin...

Embodiment 3

[0033] On the basis of Example 2, such as Figure 6 As shown, a handle 20 and an isolation plate 21 are also included, the handle 20 is fixedly installed on one side of the left part of the hopper 10, and the handle 20 is located above the limit frame 11, and the isolation plate 21 is fixedly installed In the receiving hopper 10 and located at the left part of the receiving hopper 10 , the separation plate 21 is used to block impurities and sugarcane juice falling into the receiving hopper 10 .

[0034] Such as figure 1 and Figure 4 As shown, it also includes a cleaning device 22 for preliminary cleaning of the surface of the sugarcane. The cleaning device 22 is arranged on one end of the arc guide plate 5 and the limit arc plate 6 and is connected with the intermittent transmission device 7. The cleaning device 22 comprises a third drive gear 221, a hollow shaft 222, a large bearing 223 and a circular cleaning block 224, and the large bearing 223 is fixedly installed on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com