Air sampling bottle

An air sampling and bottle cap technology, applied in the sampling device and other directions, can solve the problems of affecting the test results, being easily adsorbed on the side wall of the bottle body, and complex docking mechanism, and achieving accurate measurement data, convenient docking, and convenient storage and release. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

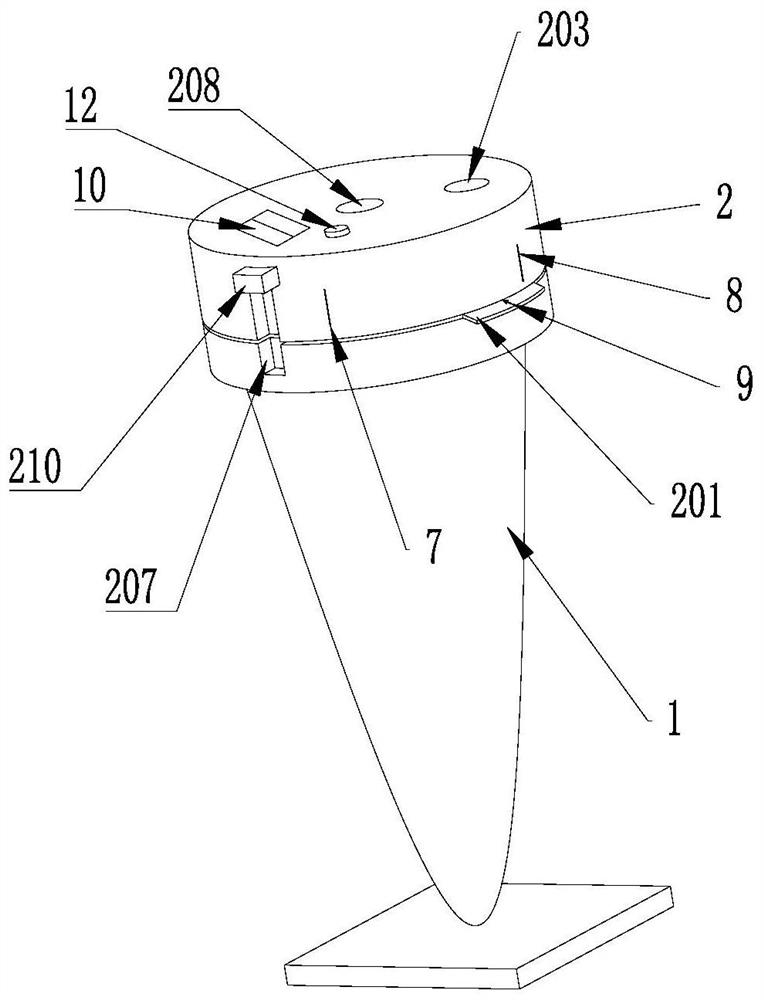

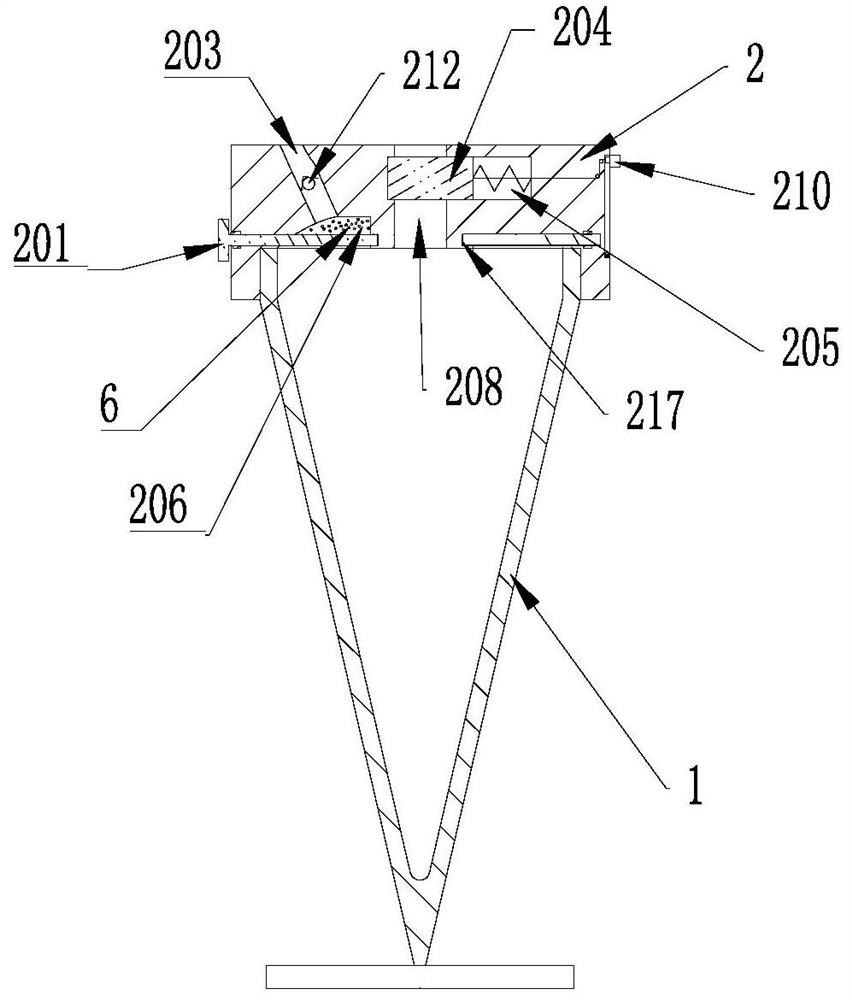

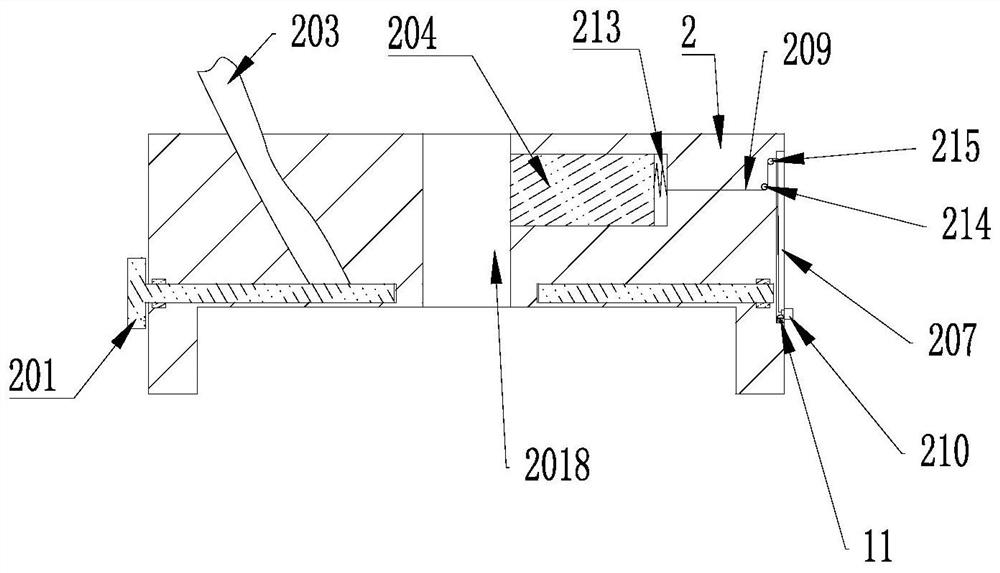

[0025] In order to better understand the present invention, the following combination Figure 1 to Figure 5 Embodiments of the present invention will be explained in detail.

[0026] Such as figure 1 with figure 2 The shown air sampling bottle includes a conical bottle body 1 and a bottle cap 2 . Of course, the conical bottle body 1 can also be designed as a non-conical bottle body, as long as the cavity in the bottle is conical. The conical bottle body 1 and the bottle cap 2 are connected in a threaded seal, and a sealing ring corresponding to the bottle mouth is arranged on the inner side of the bottle cap 2 . The bottle cap 2 includes an air inlet channel 203, an air outlet 208, a cleaning particle placement groove 206, an annular groove 217, a blocking plate 201 and a sealing structure.

[0027] Such as figure 2 with Figure 5 As shown, the air intake channel 203 extends from the upper end of the bottle cap 2 to the lower end. Preferably, the air intake channel 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com