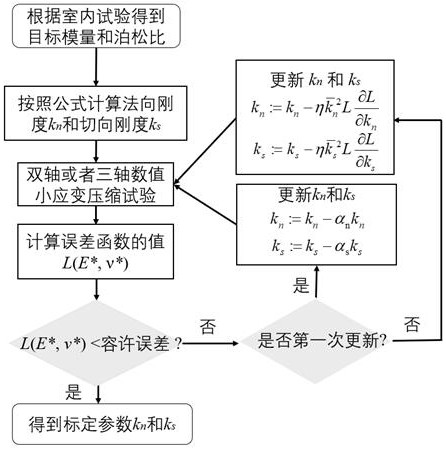

Automatic calibration method for discrete element linear stiffness parameters during geotechnical material simulation

A technology of geotechnical materials and linear stiffness, applied in the field of geotechnical engineering, can solve problems such as increased risk, affecting calibration efficiency, and model failure to achieve the best convergence efficiency, so as to promote analysis and research, good calibration convergence, and implementation process clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

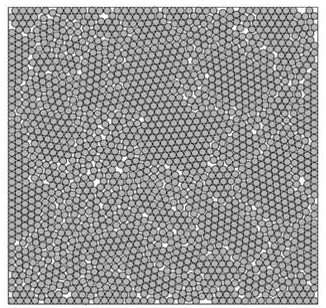

[0127] Apply the method of the present invention to a two-dimensional single-size random particle sample (such as figure 2 ), the test parameters are as follows:

[0128]

[0129] Table 1 Parameters of the two-dimensional single particle random arrangement particle model

[0130] The simulation steps are as follows:

[0131] Step (1): Determine the macroscopic parameters of the geotechnical material to be simulated through laboratory tests. The macroscopic parameters of the rock-soil material in this embodiment are: Young's modulus E is 10Gpa, and Poisson's ratio υ is 0.2.

[0132] Step (2): Input the target macroscopic parameters obtained from the test into the formula, and determine the initial estimated values of the particle contact normal stiffness and tangential stiffness in the two-dimensional model respectively with

[0133]

[0134] Among them, S is the area of the two-dimensional sample, N c is the number of contacts in the sample, r is the median ...

specific Embodiment approach 2

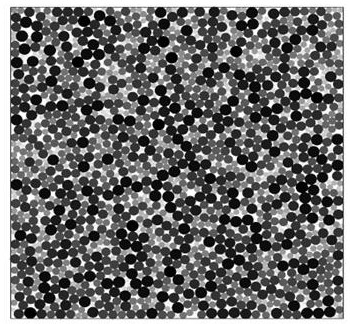

[0154] Apply the method of the present invention to the calibration of two-dimensional multi-size random particle samples (such as image 3 ), the test parameters are shown in Table 3:

[0155]

[0156] Table 3 Parameters of the two-dimensional multi-size random arrangement particle model

[0157] The simulation steps are as follows:

[0158] Step (1): Determine the macroscopic parameters of the geotechnical material to be simulated through laboratory tests. The macroscopic parameters of the rock-soil material in this embodiment are: Young's modulus E is 10Gpa, and Poisson's ratio υ is 0.2.

[0159] Step (2): Input the target macroscopic parameters obtained from the test into the formula, and determine the initial estimated values of the particle contact normal stiffness and tangential stiffness in the two-dimensional model respectively with

[0160]

[0161] Among them, S is the area of the two-dimensional sample, N c is the number of contacts in the sample,...

specific Embodiment approach 3

[0181] Apply the method of the present invention to the calibration of three-dimensional single particle size random particle samples (such as Figure 4 ), the test parameters are shown in Table 5:

[0182]

[0183] Table 5 Parameters of the three-dimensional multi-size random arrangement particle model

[0184] The simulation steps are as follows:

[0185] Step (1): Determine the macroscopic parameters of the geotechnical material to be simulated through laboratory tests. The macroscopic parameters of the rock-soil material in this embodiment are: Young's modulus E is 10Gpa, and Poisson's ratio υ is 0.2.

[0186] Step (2): Input the target macroscopic parameters obtained from the test into the formula, and determine the initial estimated values of the particle contact normal stiffness and tangential stiffness in the 3D model respectively and

[0187]

[0188] Among them, V is the volume of the three-dimensional sample, N c is the number of contacts in the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com