Rolling bearing intelligent fault diagnosis method based on multi-classification fuzzy correlation vector machine

A related vector machine and rolling bearing technology, used in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of unsatisfactory diagnosis effect and poor noise resistance, so as to improve the accuracy of fault diagnosis and realize the The effect of recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

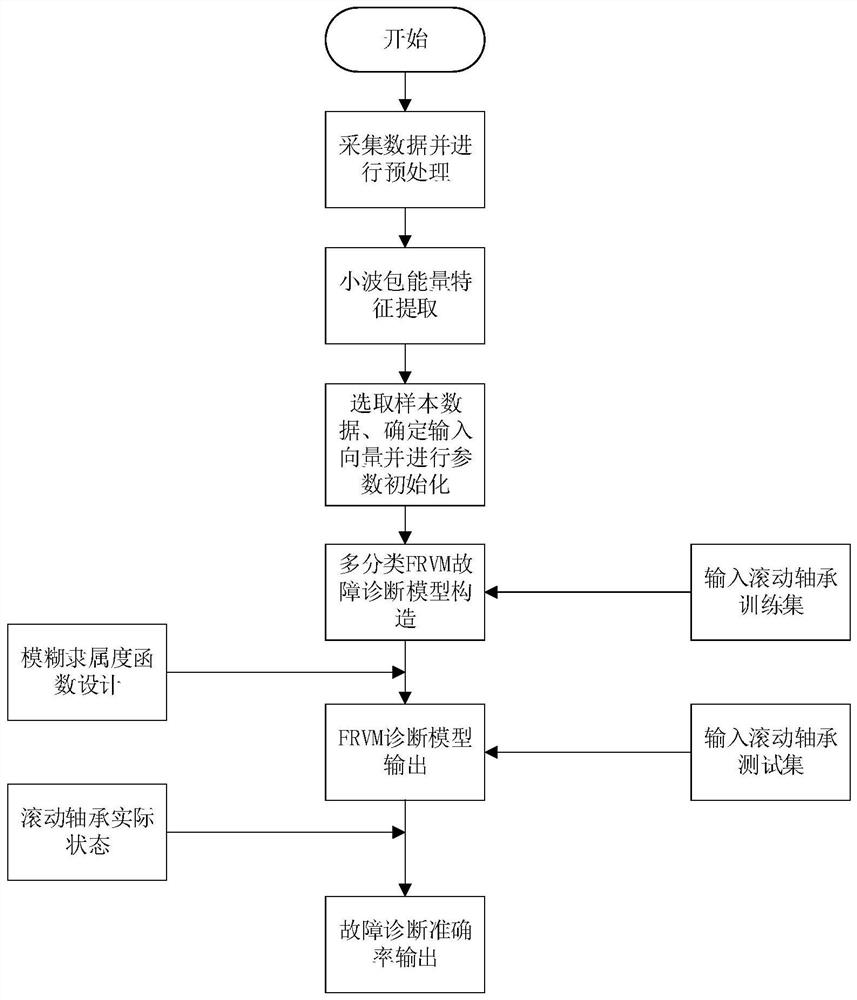

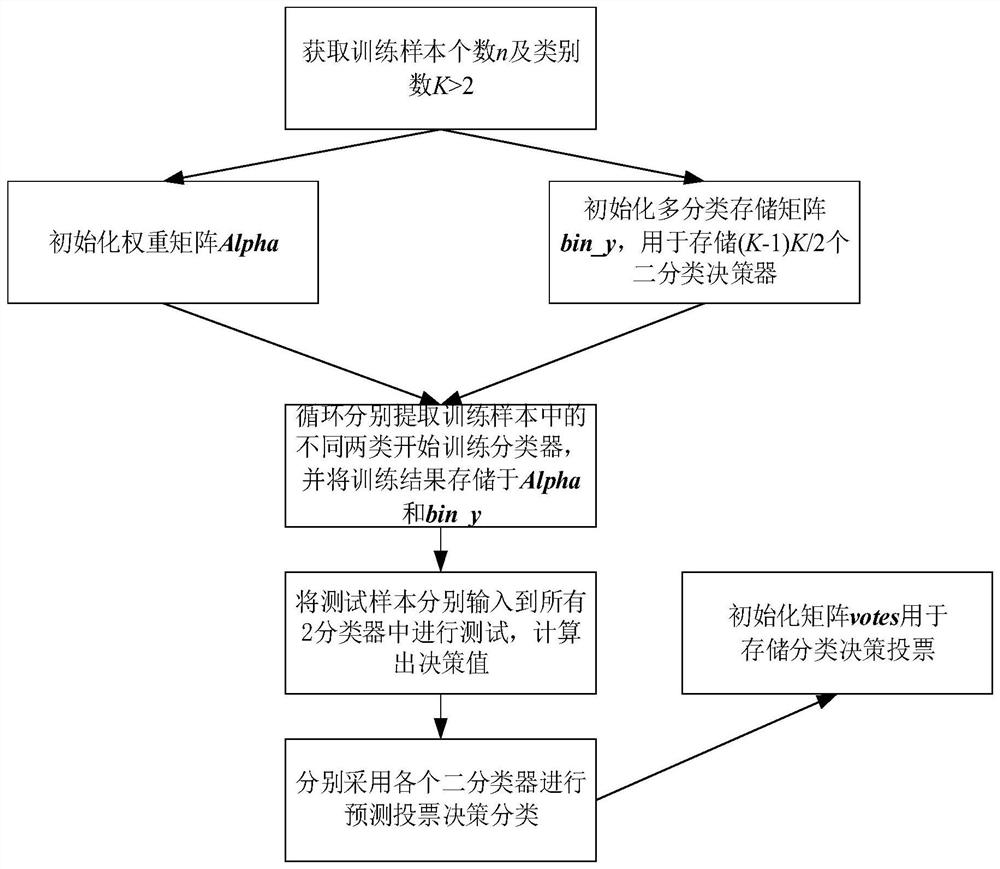

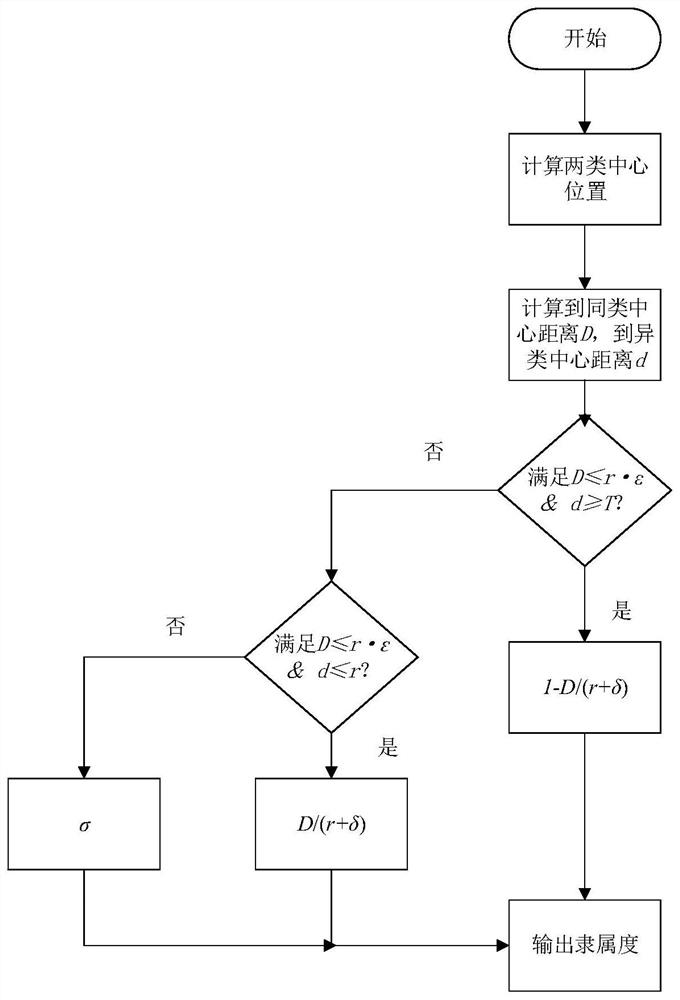

[0043] Figure 1 to Figure 8 Some embodiments according to the invention are shown.

[0044] Such as Figure 8 As shown, the rolling bearing fault diagnosis method based on multi-classification fuzzy correlation vector machine of the present invention comprises the following steps:

[0045] S1. Acceleration sensors are used to collect data from vibration signals of rolling bearings during operation;

[0046] S2, performing segmentation processing on the data samples of the vibration data signal of the rolling bearing, wherein each segment has statistical significance;

[0047] S3. Using wavelet packets to analyze each section of the vibration signal, extracting its wavelet packet energy fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com