SMT production JIT material calling method and system and storage medium

A storage medium and material-calling technology, applied to electrical components, electrical components, etc., can solve problems such as low production efficiency, cumbersome process, and long working hours, and achieve the effect of improving material-calling efficiency and simplifying the material-calling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

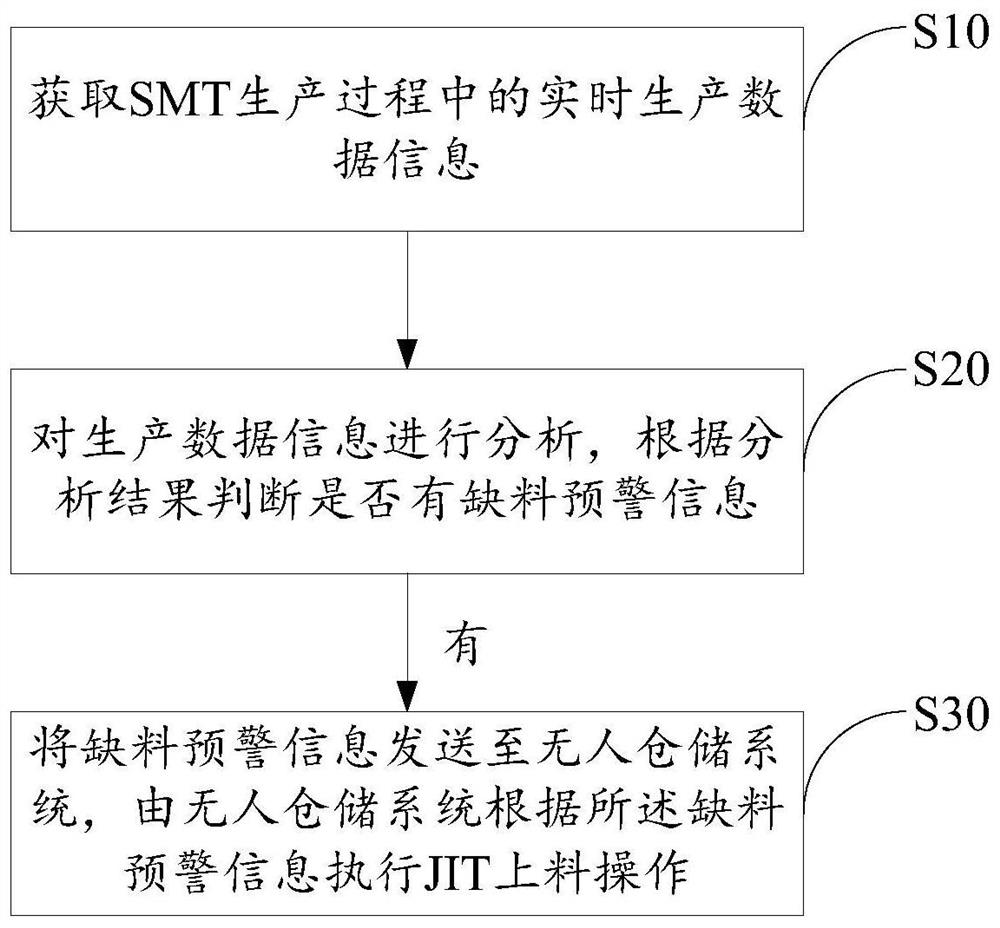

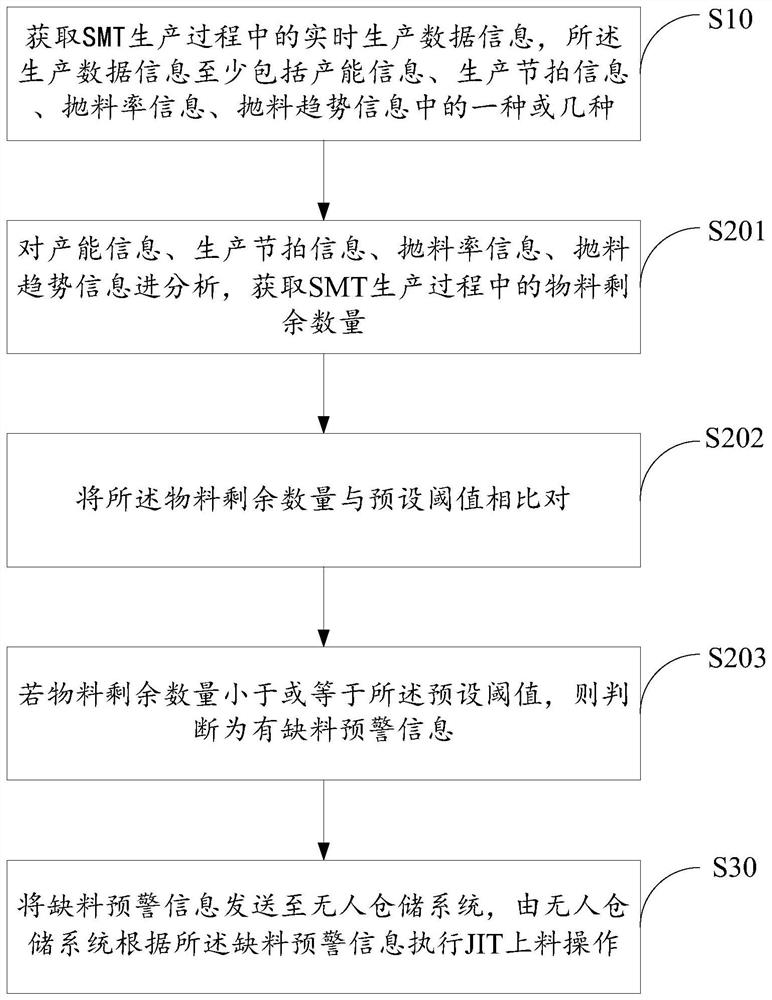

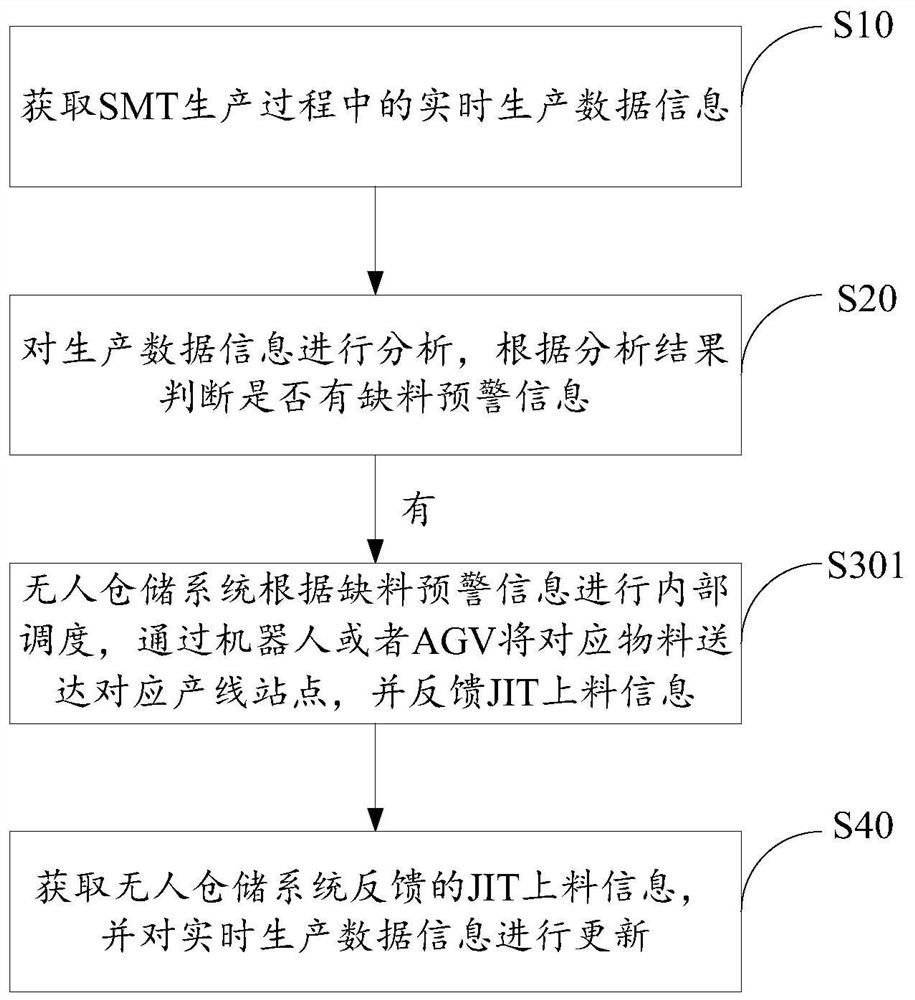

[0040] Please refer to Figure 1 to Figure 9 , in view of most of the current electronic manufacturing industries, the raw material inventory pressure of the production line is high, the manual call time is long, the time is inaccurate, and the process is cumbersome, resulting in long working hours, high costs, and low production efficiency. The SMT production JIT (Just In Time, punctual) method of calling material in human warehouse. The present invention is based on the basic idea of JIT, "produce required products only when required, according to required quantity", and realizes a low-stock, fast-running production and ordering system. In the production process, the production raw materials are monitored, and the raw materials that are about to be exhausted are warned in advance.

[0041] Under the condition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com