Working method of non-single-cavity electric appliance

A working method and cavity technology, which is applied to steam cooking utensils, roasters/barbecue grids, timing control ignition mechanisms, etc., can solve problems such as exceeding the rated power, and achieve a more user-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

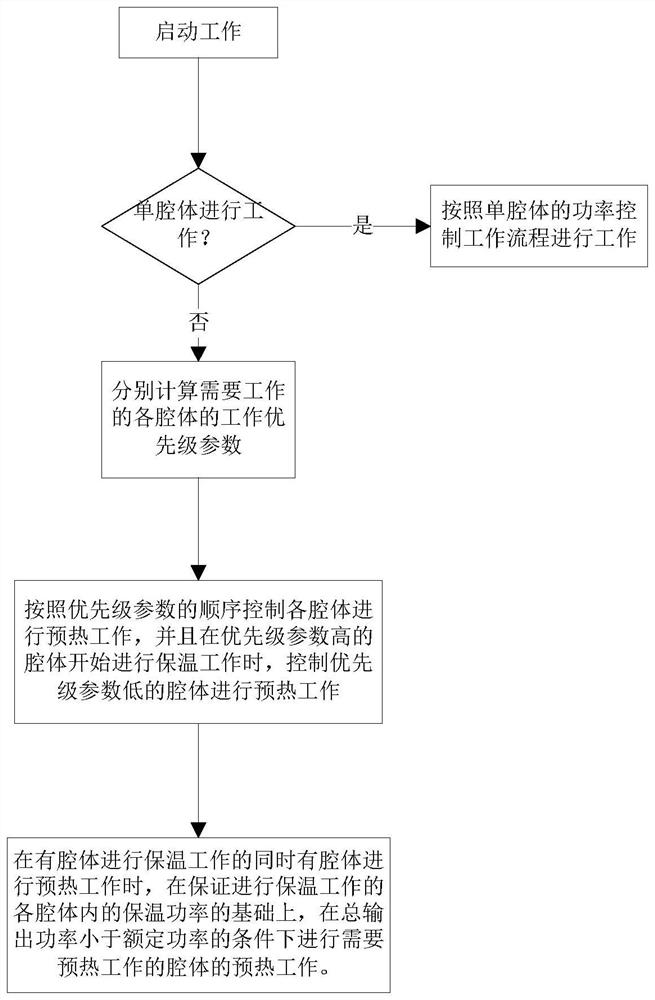

[0018] Such as figure 1 As shown, the working method of the non-single-chamber electrical appliance in this embodiment is: when the non-single-chamber electrical appliance has only one cavity to work, work according to the single-chamber power control workflow;

[0019] When at least two cavities of the non-single-cavity electrical appliance need to be preheated, the work priority parameters of the cavities that need to be worked are calculated respectively, and the cavities are controlled to perform the preheating work according to the order of the priority parameters, and When the cavity with high priority parameter starts to keep warm, control the cavity with low priority parameter to perform preheating work;

[0020] When there is a cavity for heat preservation work and a cavity for preheating work at the same time, on the basis of ensuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com