Environment-friendly aluminum alloy sectional material extruder

A technology of aluminum alloy profiles and extrusion machines, which is applied in the field of extrusion machines, and can solve the problem that the extrusion of aluminum alloy profiles is not applicable. The left side of the controller is installed on the right side of the reduction box, and the upper part of the funnel is installed under the outlet, etc., so as to facilitate the extrusion operation and shorten the fixed point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

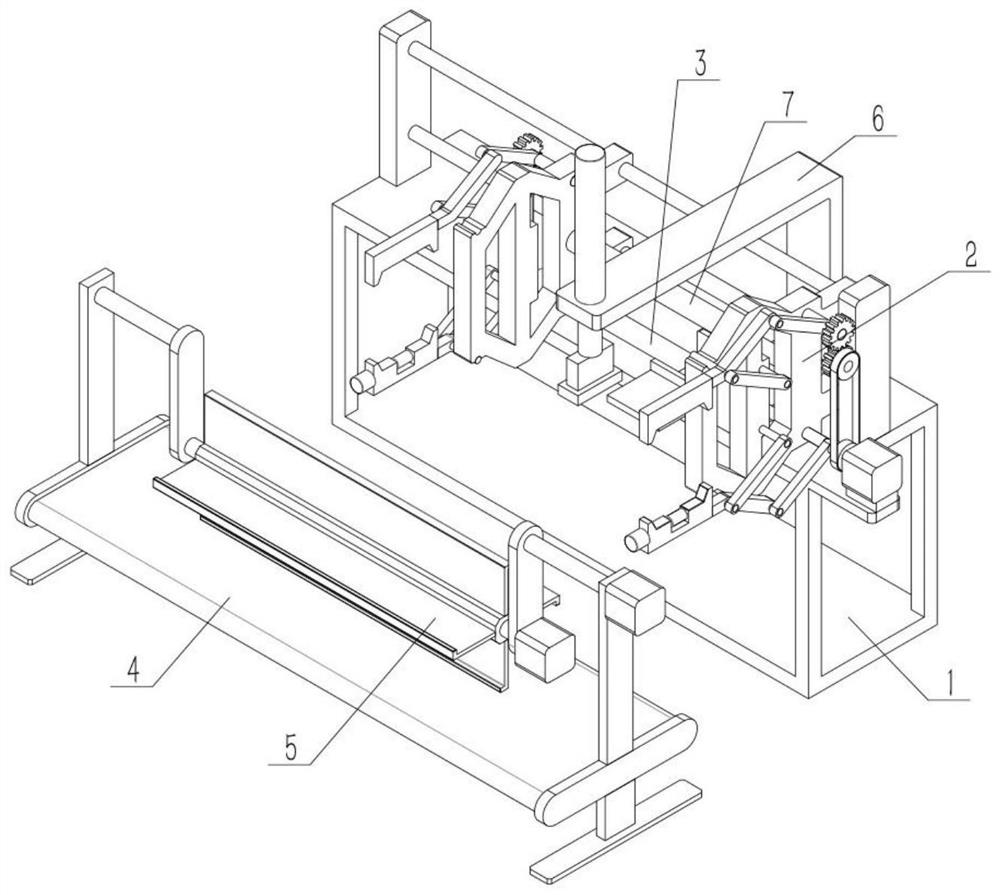

[0029] like Figure 1-7 As shown, an environment-friendly aluminum alloy profile extrusion machine includes an operating table 1, an opening and closing mechanism 2, a linkage 3, a running mechanism 4, a two-way transport platform 5, an extrusion mechanism 6 and an electric telescopic rod III 7, and the opening and closing mechanism 2 There are two mirror images, one opening and closing mechanism 2 is fixedly connected to the rear end of the upper side of the console 1, and the other opening and closing mechanism 2 is slidably connected to the upper side of the console 1, between the two opening and closing mechanisms 2 Through the transmission connection of the linkage 3, the running mechanism 4 is set on the left side of the console 1, the two-way transport platform 5 is fixed on the running mechanism 4, the extrusion mechanism 6 is fixed on the console 1, and the front and rear sides of the electric telescopic rod III7 The ends are fixedly connected to the inner ends of the...

specific Embodiment approach 2

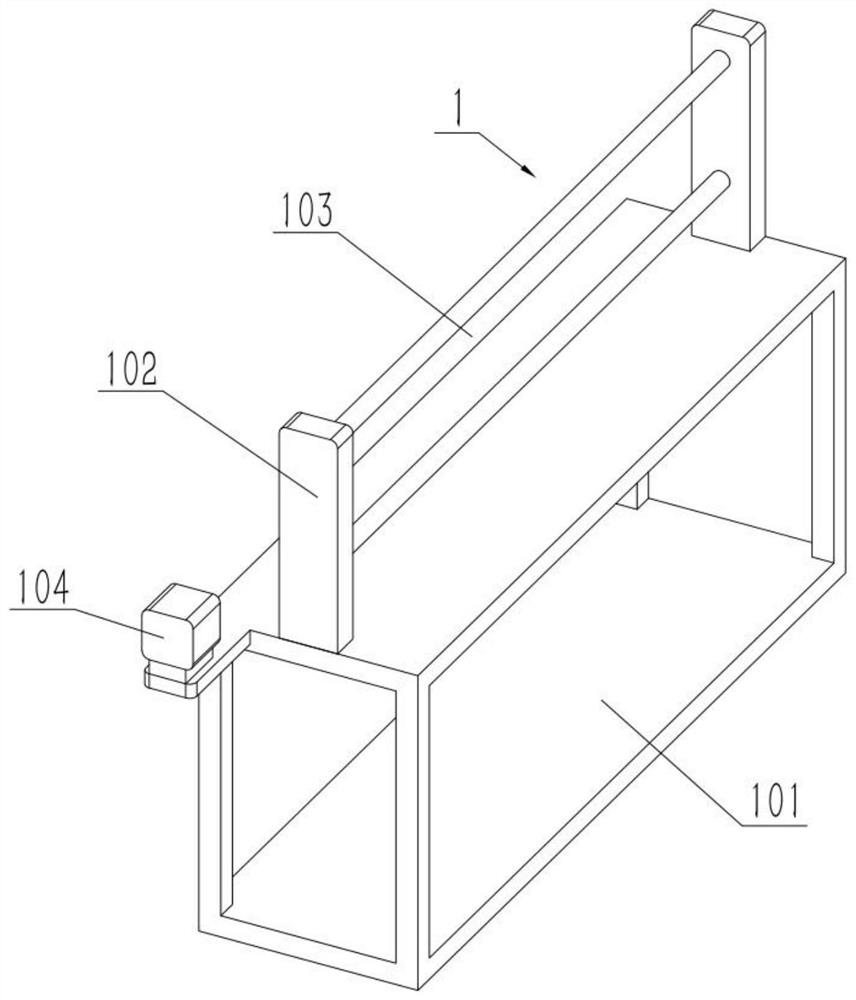

[0031] like Figure 1-7 As shown, the console 1 includes a console body 101, a side seat 102, a shaft 103, and a motor I 104. The front and rear ends of the upper end of the console body 101 are respectively fixed with a side seat 102, and two shafts 103 are provided, each The front and rear ends of the shaft 103 are fixedly connected to the two side seats 102 respectively, and the motor I 104 is fixedly connected to the console body 101 .

specific Embodiment approach 3

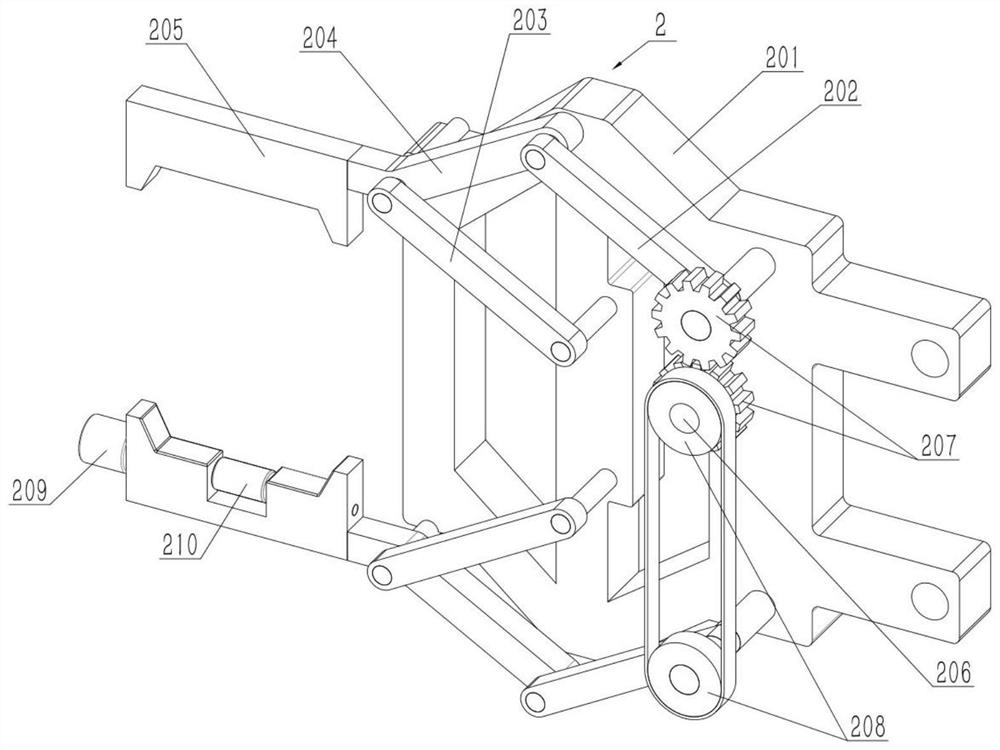

[0033] like Figure 1-7 As shown, the opening and closing mechanism 2 includes a skeleton 201, a rod I 202, a rod II 203, a rod III 204, an opening and closing part 205, a shaft I 206, a gear 207 and a pulley 208, a rod I 202, a rod II 203, a rod III 204 and an opening and closing part 205 There are two mirror images, the right ends of the two rods I 202 are rotatably connected to the skeleton 201, the left ends of the two rods I 202 are hinged to the right end of a rod III 204, and the left ends of the two rods III 204 are hinged to a rod II 203. At the left end, the right ends of the two rods II 203 are hingedly connected to the frame 201, the left ends of the two rods III 204 are fixedly connected to an opening and closing part 205, the shaft I 206 is rotatably connected to the frame 201, and the right end of the rod I 202 on the upper side is connected to the shaft A gear 207 is fixedly connected to I206, and the two gears 207 are meshed for transmission. A pulley 208 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com