A method for installing a side-connected high-pressure escape cabin in a lifeboat

A technology for escape cabins and lifeboats, which is applied to lifesaving in water, ships, and ship safety, etc., can solve the problems of reducing the overall strength of the lifeboats, increasing the sailing resistance of the boat, and increasing the sailing resistance, so as to improve the installation accuracy and watertight effect, and improve the overall Longitudinal strength, the effect of avoiding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

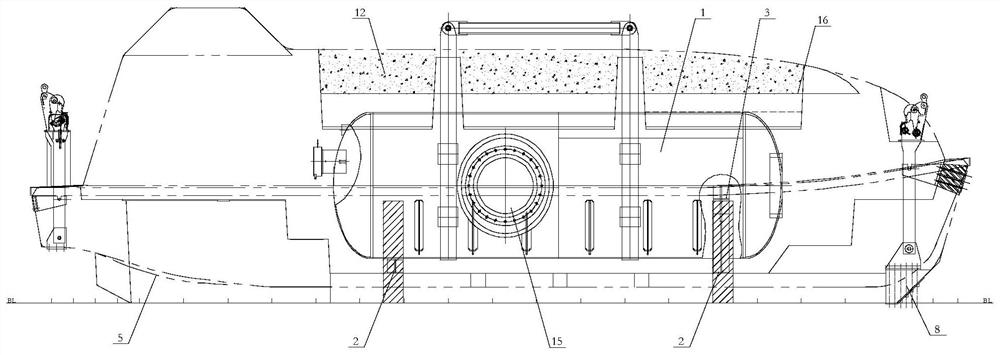

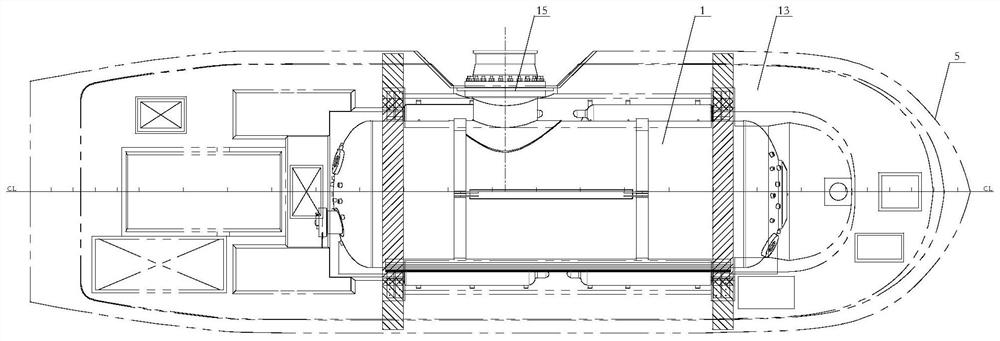

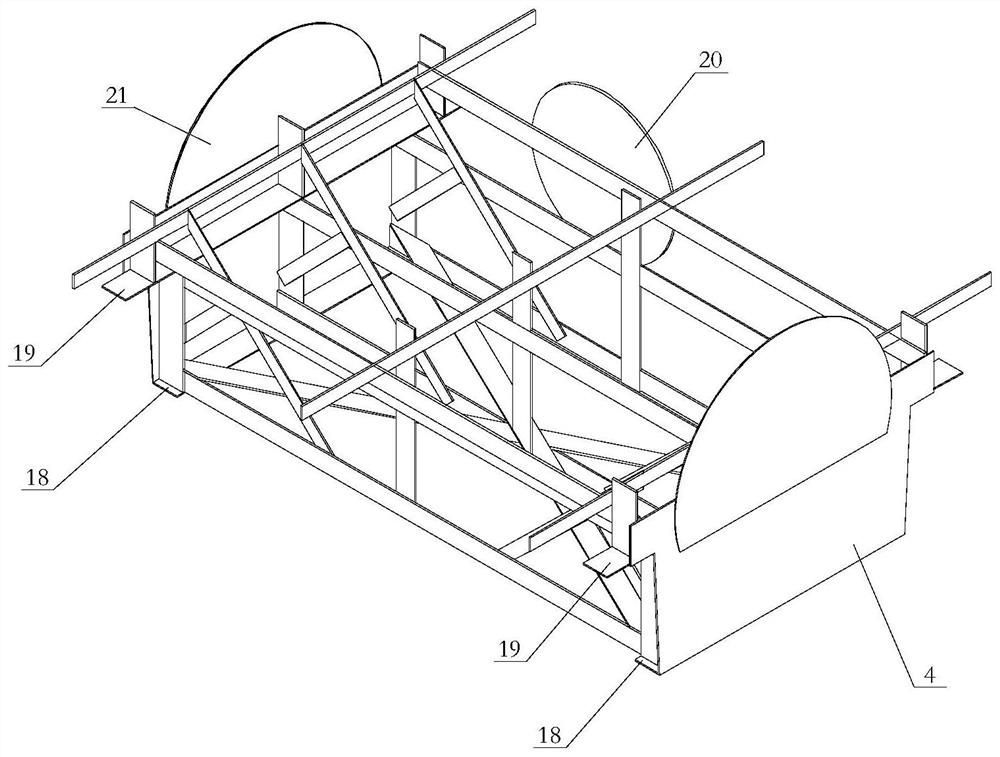

[0042] combine Figure 1 to Figure 8 As shown, the method for installing a side-mounted hyperbaric escape cabin provided by the present invention in a lifeboat will be described in detail.

[0043]A method for installing a side-connected high-pressure escape cabin in a lifeboat, wherein the high-pressure escape cabin is installed in the lifeboat in a side-connected manner. The side connection installation of the high-pressure escape cabin can prevent the large-sized docking interface docked with the escape channel of the mother ship from protruding from the longitudinal centerline of the bottom of the boat, resulting in an increase in the navigation resistance of the lifeboat. The high-pressure escape cabin can be cylindrical or other shapes. The bottom of the high-pressure escape cabin is provided with a horizontal base for installation, and two side supports are provided on the side to integrate the external air cylinders and pipelines of the high-pressure escape cabin into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com