Multi-working condition template of tunnel lining trolley

A technology for lining trolleys and multiple working conditions, which can be used in tunnel lining, tunnel, wellbore lining and other directions, which can solve the problems of short tunnel mileage, waste of resources, and inability to directly apply tunnels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

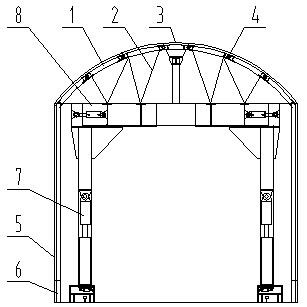

[0015] As shown in the figure, the tunnel lining trolley multi-condition formwork includes a dome formwork and a side wall formwork. The dome formwork includes a plurality of dome formwork standard sections 1, adjusting screws 2 and vault formwork adjustment sections 3 , the vault formwork is formed by connecting a plurality of vault formwork standard sections 1 and vault formwork adjustment sections 3 through hinge pins 4; the side wall formwork includes a side wall formwork standard section 5 and a side wall formwork adjustment section 6. The formwork adjustment section 6 is located directly below the standard section 5 of the sidewall formwork, and the height of the sidewall formwork can be raised and lowered by increasing or decreasing the sidewall formwork adjusting section 6; Height lift for gantry.

[0016] The above is the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com