A cylinder and its piston position detection device

A detection device and cylinder technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of complex structure, unstable detection accuracy, unreliability, etc., and achieve simple structure, best positioning reliability and stability, and excellent anti-disturbance performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

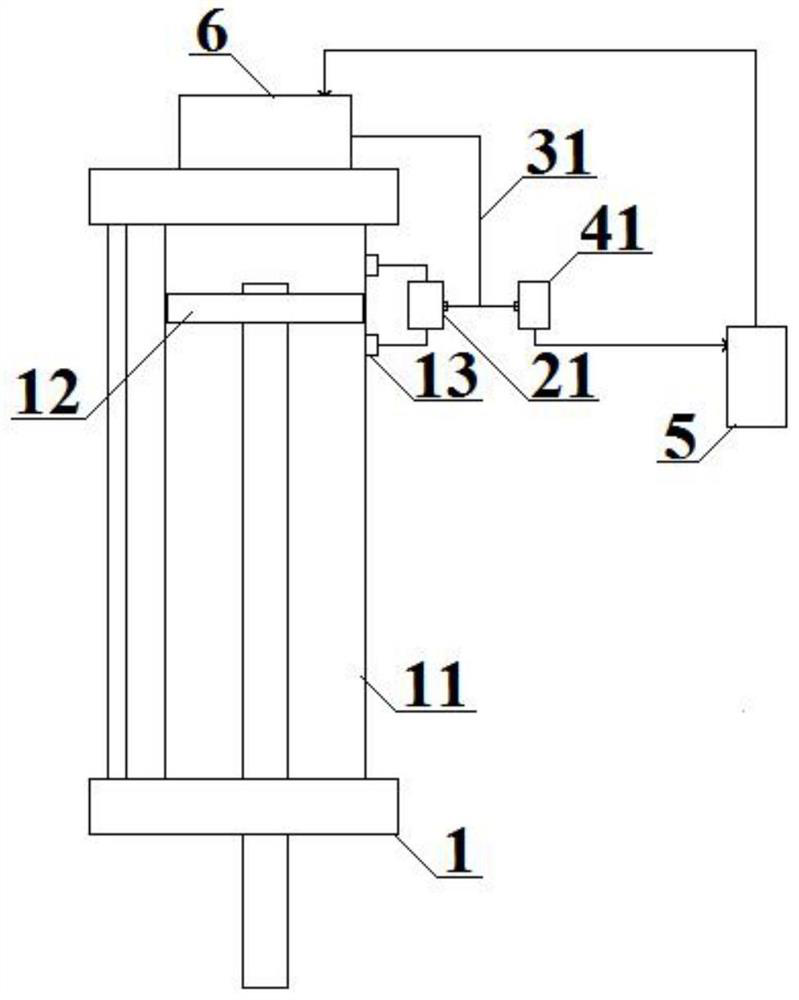

[0035] see figure 1 , a cylinder, comprising: a cylinder main body 1 and a piston in-position detection device;

[0036] The cylinder body 11 of the cylinder main body 1 is provided with a first differential pressure detection port 13, the first differential pressure detection port 13 includes: a first gas port and a second gas port, and the first gas port and the second gas port The distance in the movement direction of the piston is greater than the thickness of the piston 12 of the cylinder main body 1; thus, a differential pressure triggering structure is formed, that is, once the piston 12 is between the first air port and the second air port, the first air The first air port and the second air port are respectively connected to the high-pressure chamber and the low-pressure chamber, resulting in an obvious pressure difference between the two air ports, and by sensing the pressure difference signal, the piston position can be positioned with high time efficiency; compared...

Embodiment 2

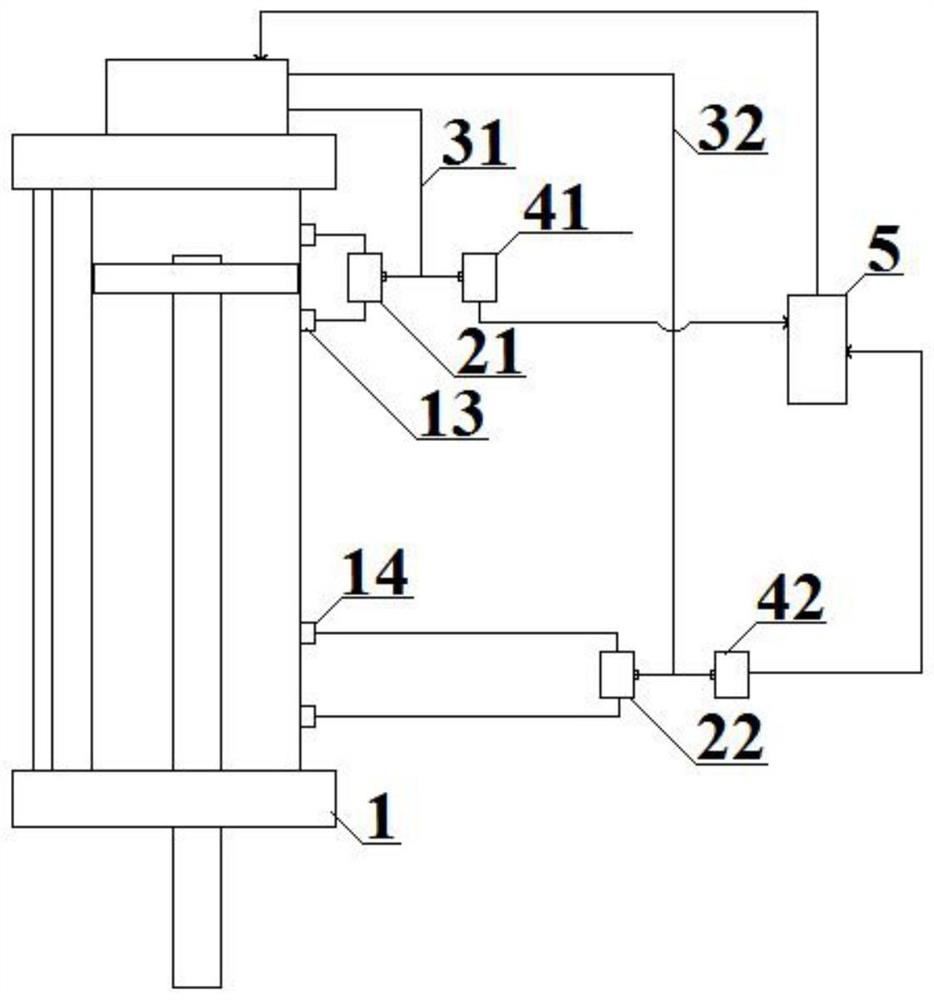

[0045] This embodiment increases the number of differential pressure detection ports and corresponding piston in-position detection devices on the basis of Embodiment 1, so that multi-point in-position detection of the piston can be realized, so that in-position control can be realized, and the piston of the cylinder can also be controlled. stroke, so as to control the length of the external force arm.

[0046] The following takes two differential pressure detection ports as an example for description.

[0047] see figure 2 , the first differential pressure detection port 13 is arranged at the bottom of the cylinder body 11, the second differential pressure detection port 14 is arranged at the top of the cylinder body 11, and each of the differential pressure detection ports is correspondingly connected to a The piston in-position detection device is described; thus, the control of the upper and lower limit positions is formed, and the reciprocating control of the piston 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com