3D structured light 940nm narrow-band optical filter and preparation method thereof

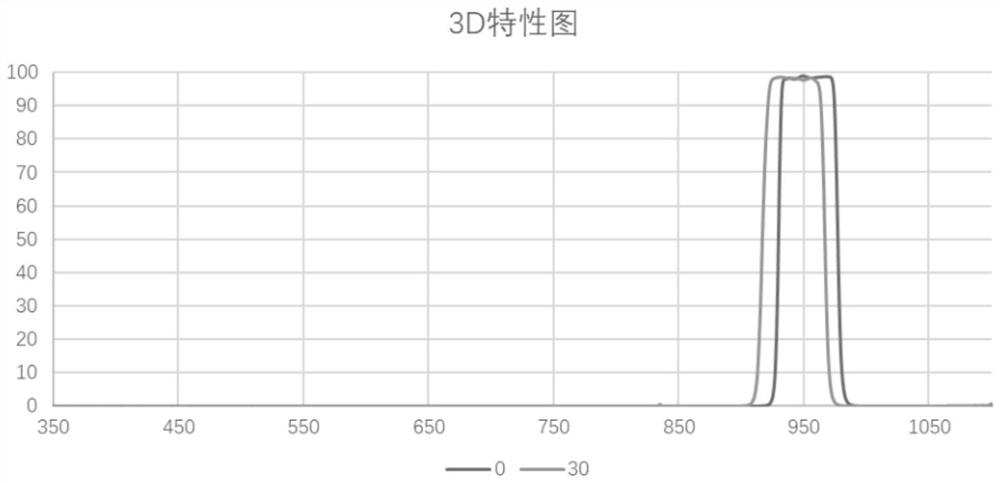

A technology of narrow-band optical filter and structured light, which is applied in the field of optical filter to achieve the effect of accurate wavelength positioning and good steepness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

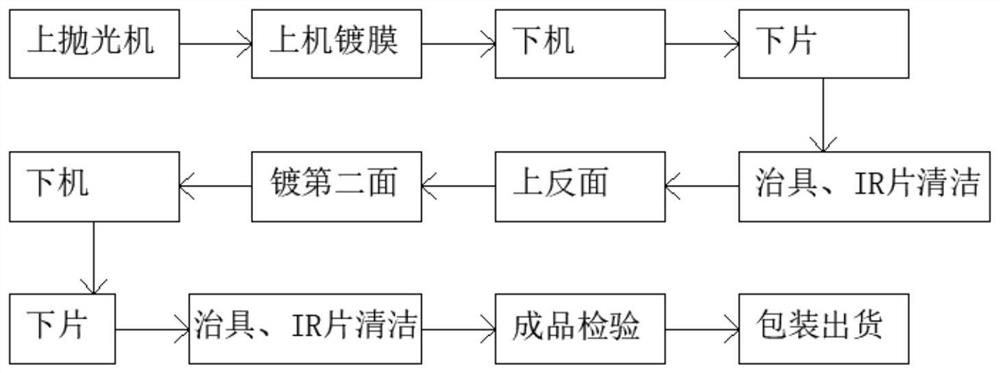

[0020] see figure 1 , in an embodiment of the present invention, a 3D structured light 940nm narrow-band filter includes a substrate, one side of the substrate is alternately vapor-deposited with silicon oxide layers and hydrogenated silicon layers, and the other side of the substrate is alternately vapor-deposited with silicon oxide layers and For the hydrogenated silicon layer, the total number of layers of the silicon oxide layer and the hydrogenated silicon layer on each side is set to 20-40 layers.

[0021] Preferably, the silicon oxide layer is set as a silicon dioxide layer, and the hydrogenated silicon layer is set as a silicon tetrahydrogen layer.

[0022] Preferably, the thickness of the silicon oxide layer on each side is set to 1300-2000 nm, and the thickness of the hydrogenated silicon layer on each side is set to 400-800 nm.

[0023] Preferably, the substrate is set to be AF32 glass or D263T glass.

[0024] A preparation method of a 3D structured light 940nm na...

Embodiment 2

[0040] see figure 1 with figure 2 , in an embodiment of the present invention, a 3D structured light 940nm narrow-band filter includes a substrate, one side of the substrate is alternately vapor-deposited with silicon oxide layers and hydrogenated silicon layers, and the other side of the substrate is alternately vapor-deposited with silicon oxide layers and For the hydrogenated silicon layer, the total number of layers of the silicon oxide layer and the hydrogenated silicon layer on each side is set to 27 layers.

[0041] Preferably, the silicon oxide layer is set as a silicon dioxide layer, and the hydrogenated silicon layer is set as a silicon tetrahydrogen layer.

[0042] Preferably, the thickness of the outermost silicon oxide layer on each side is set to 100 nm, and 100 nm is the outermost layer in order to prevent the hydrogenated silicon layer from reacting with components in the air.

[0043] Preferably, the substrate is set to be AF32 glass or D263T glass.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com