Patents

Literature

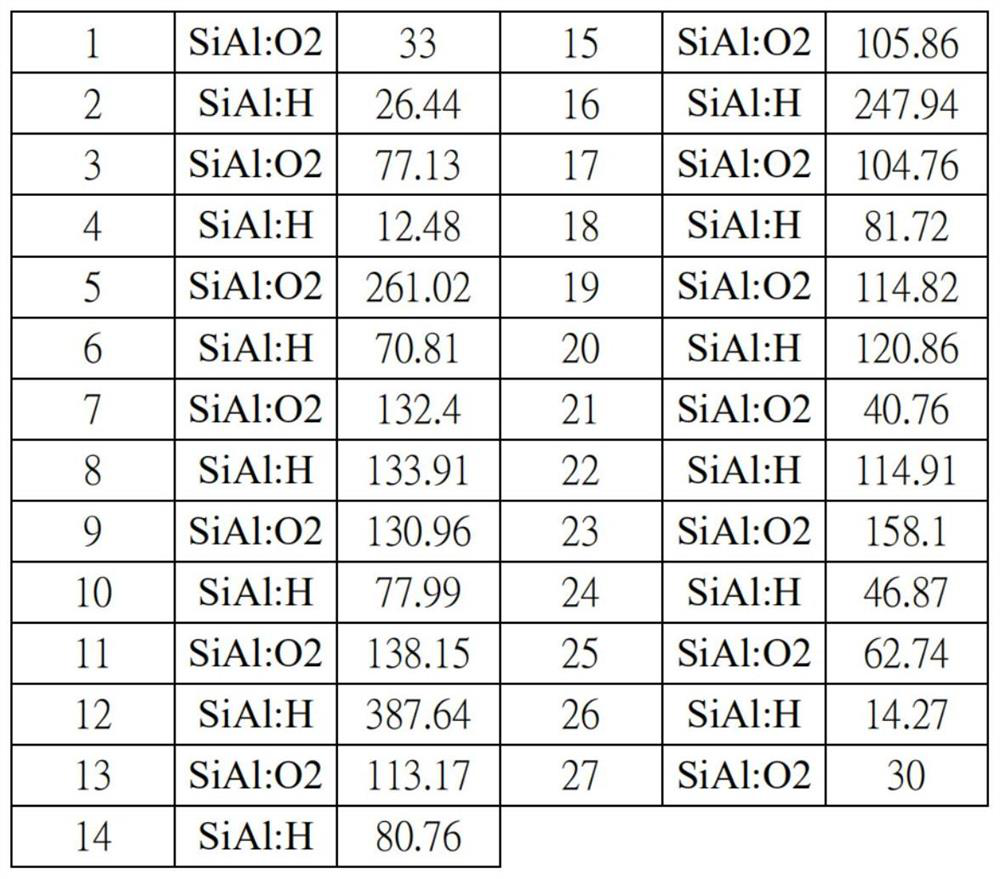

61 results about "Silica hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

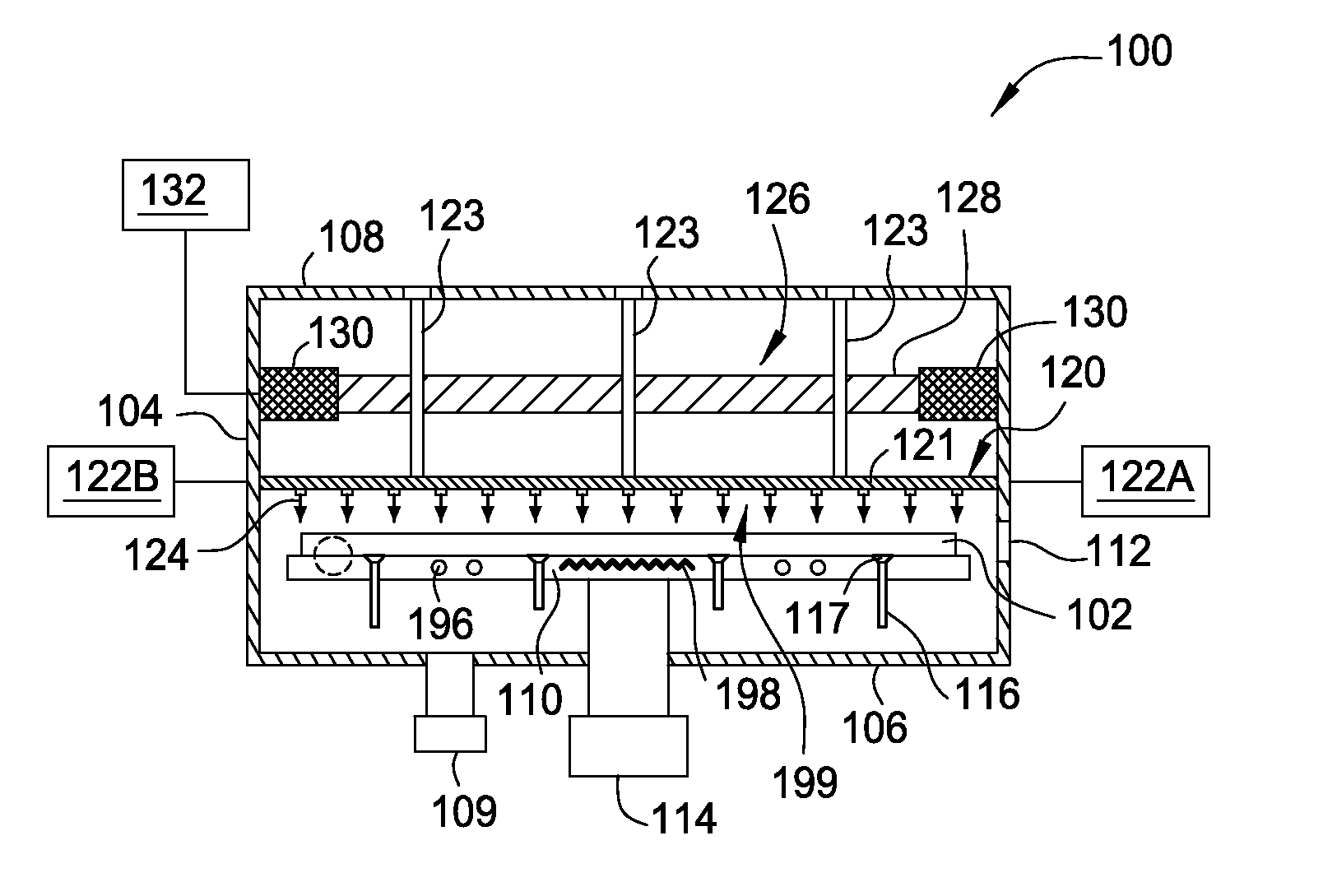

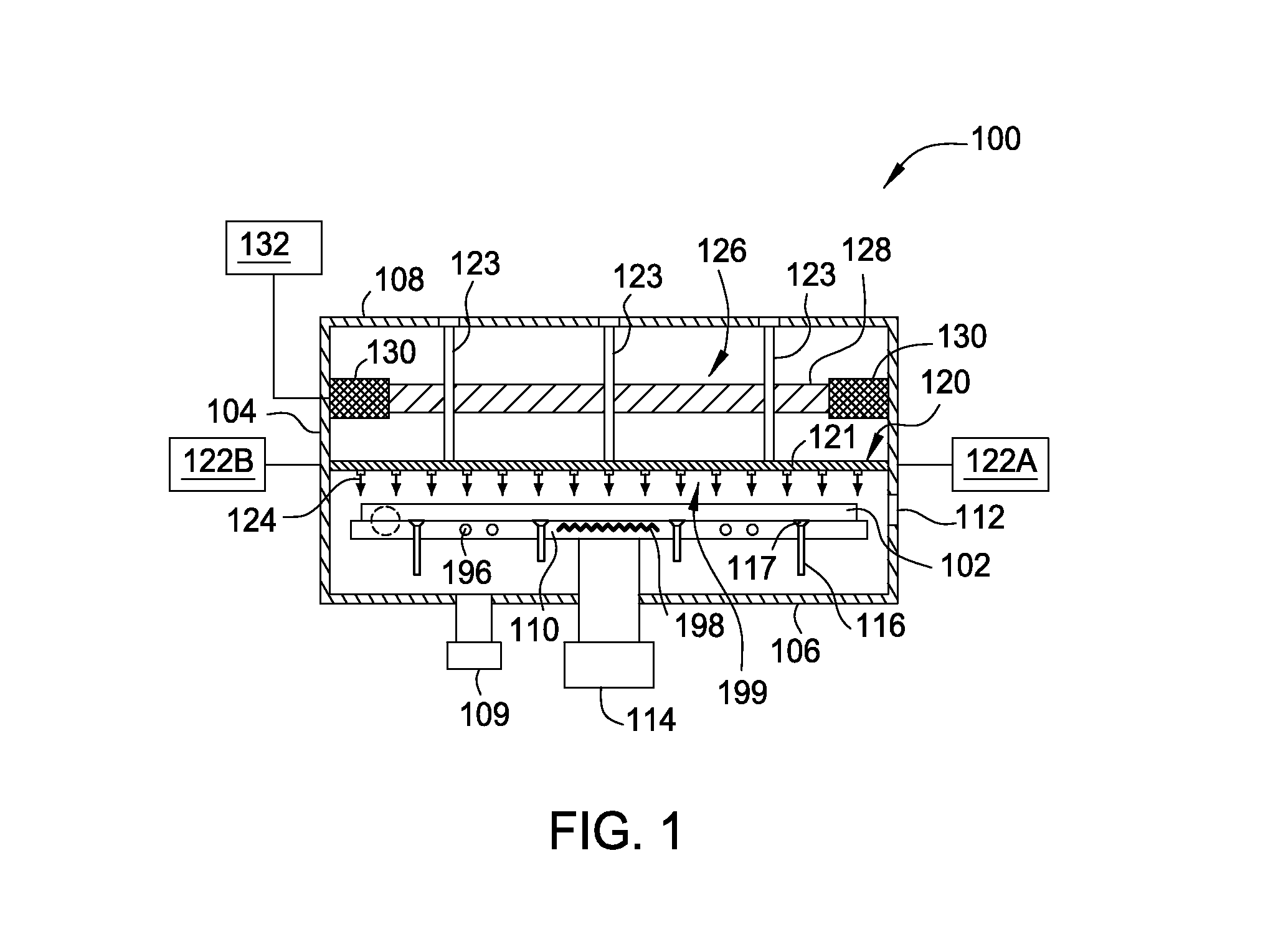

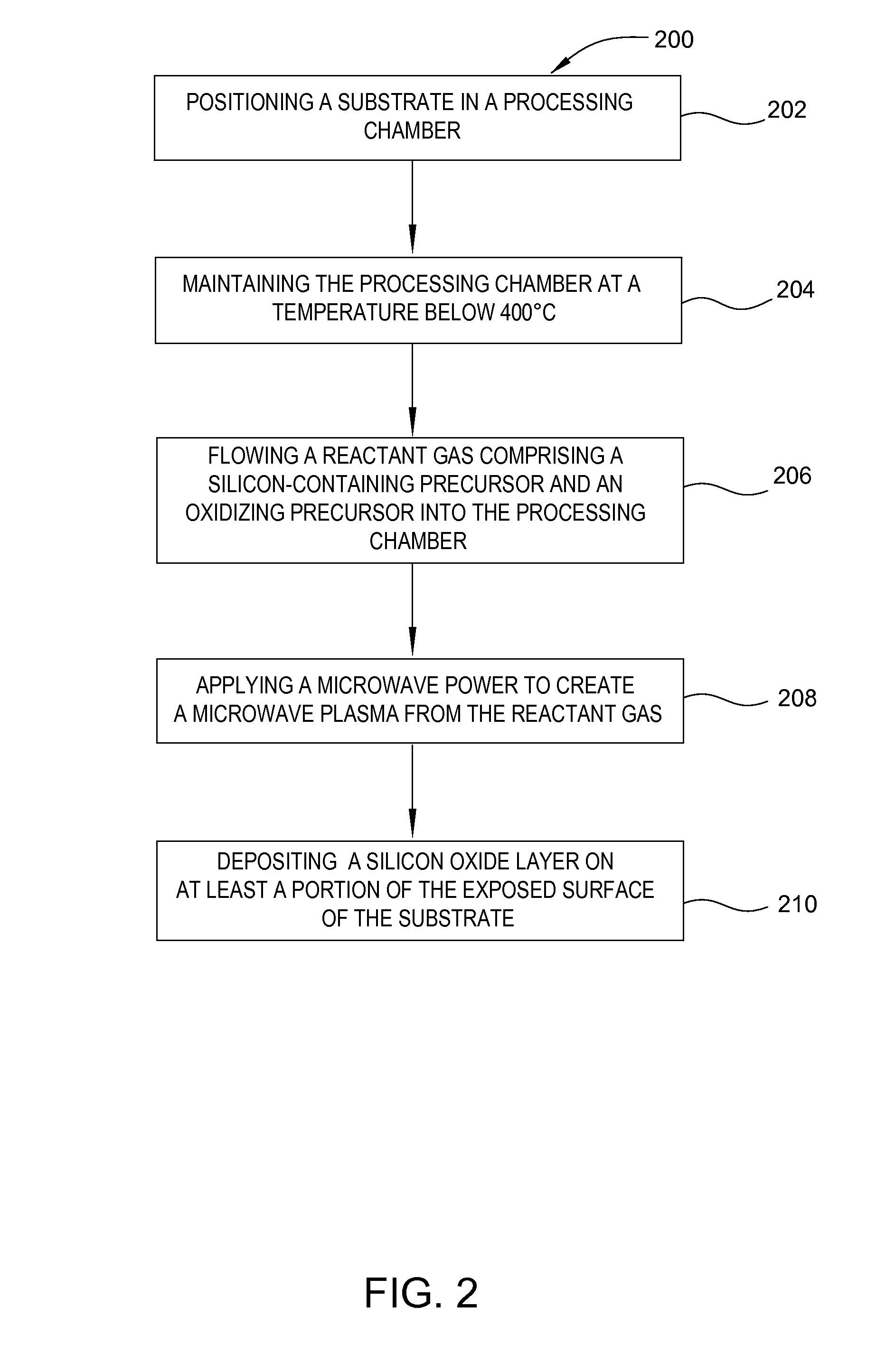

Siox process chemistry development using microwave plasma CVD

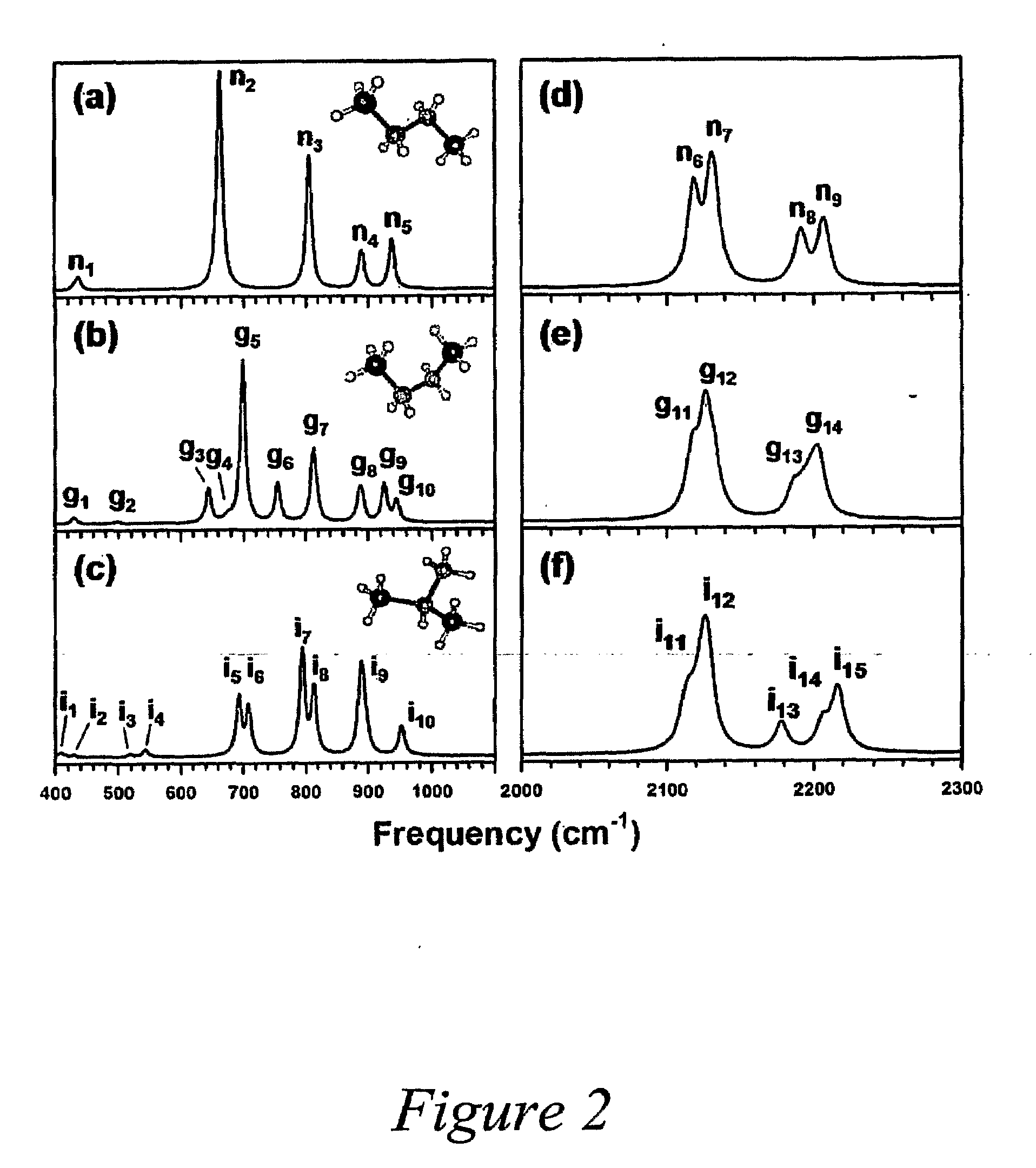

InactiveUS20130302999A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilica hydridePhysical chemistry

Methods for processing a substrate are described herein. Methods can include positioning a substrate in a processing chamber, maintaining the processing chamber at a temperature below 400° C., flowing a reactant gas comprising either a silicon hydride or a silicon halide and an oxidizing precursor into the process chamber, applying a microwave power to create a microwave plasma from the reactant gas, and depositing a silicon oxide layer on at least a portion of the exposed surface of a substrate.

Owner:APPLIED MATERIALS INC

Method for chemical vapor deposition of silicon on to substrates for use in corrosive and vacuum environments

InactiveUS7070833B2Improve propertiesReduce outgassingPretreated surfacesSolid state diffusion coatingRoom temperatureSurface conditions

A method of passivating the surface of a substrate to protect the surface against corrosion, the surface effects on a vacuum environment, or both. The substrate surface is placed in a treatment environment and is first dehydrated and then the environment is evacuated. A silicon hydride gas is introduced into the treatment environment, which may be heated prior to the introduction of the gas. The substrate and silicon hydride gas contained therein are heated, if the treatment environment was not already heated prior to the introduction of the gas and pressurized to decompose the gas. A layer of silicon is deposited on the substrate surface. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the treatment environment. The substrate is then cooled and held at a cooled temperature to optimize surface conditions for subsequent depositions, and the treatment environment is purged with an inert gas to remove the silicon hydride gas. The substrate is cycled through the silicon depositing step until the surface of the substrate is covered with a layer of silicon. The treatment environment is then evacuated and the substrate cooled to room temperature.

Owner:SILCOTEK CORP

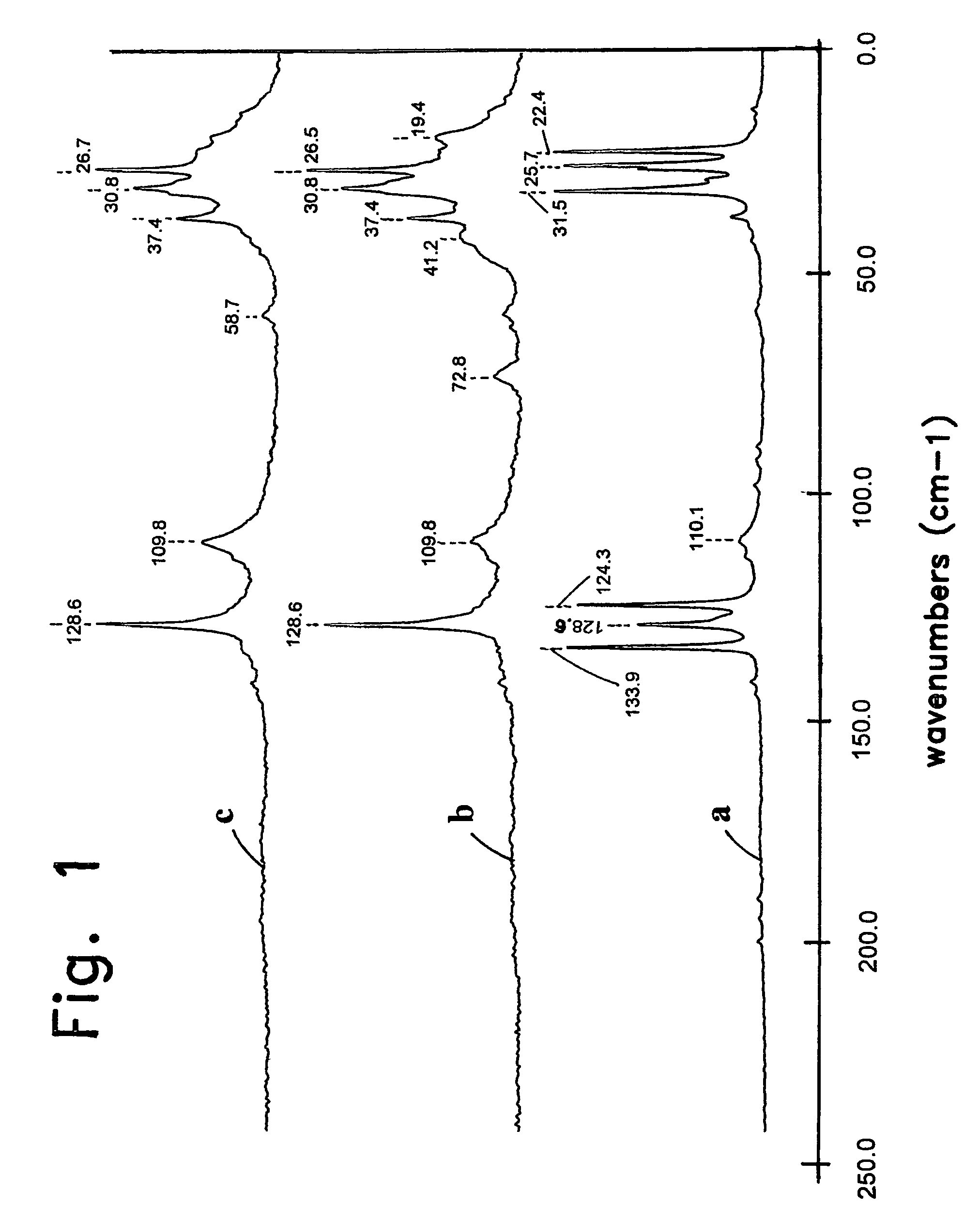

Elastomer, its preparation and use

InactiveUS6056976AEasy to prepareMeet the requirements of mechanical propertiesPowder deliveryPharmaceutical non-active ingredientsElastomerSilicon

The invention relates to a siloxane-based elastomer intended for controlling the permeation of drugs, wherein the elastomer includes 3,3,3,-trifluoropropyl groups attached to the Si-atoms of the siloxane units. The invention relates also to a method for the preparation of a siloxane-based elastomer including 3,3,3,-trifluoropropyl substituents, where the elastomer is intended for controlling the permeation of drugs. In the method either i) a 3,3,3,-trifluoropropyl-substituted vinyl-functional polysiloxane component and a silicon hydride-functional crosslinking agent are crosslinked in the presence of a catalyst, or ii) a 3,3,3,-trifluoropropyl-substituted polysiloxane component is crosslinked in the presence of a peroxide catalyst.

Owner:OY SCHERING +1

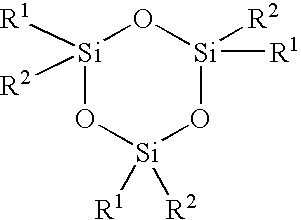

Method for making microporous silicone resins with narrow pore-size distributions

A method for preparing a microporous silicone resin which can be used to form low dielectric constant films useful for electrical insulating coatings on electronic devices comprising (A) contacting a hydridosilicon containing resin with an alkenyltriarylsilane in the presence of a platinum group metal-containing hydrosilation catalyst effecting formation of a silicon resin where at least 5 percent of silicon atoms are substituted with at least one triarylsilylalkylene group and at least 45 percent of silicon atoms are substituted with at least one hydrogen atom and (B) heating the silicon resin of step (A) in an inert atmosphere at a temperature sufficient to effect thermolysis of the triarylsilylalkylene groups from the silicon atoms.

Owner:DOW CORNING CORP

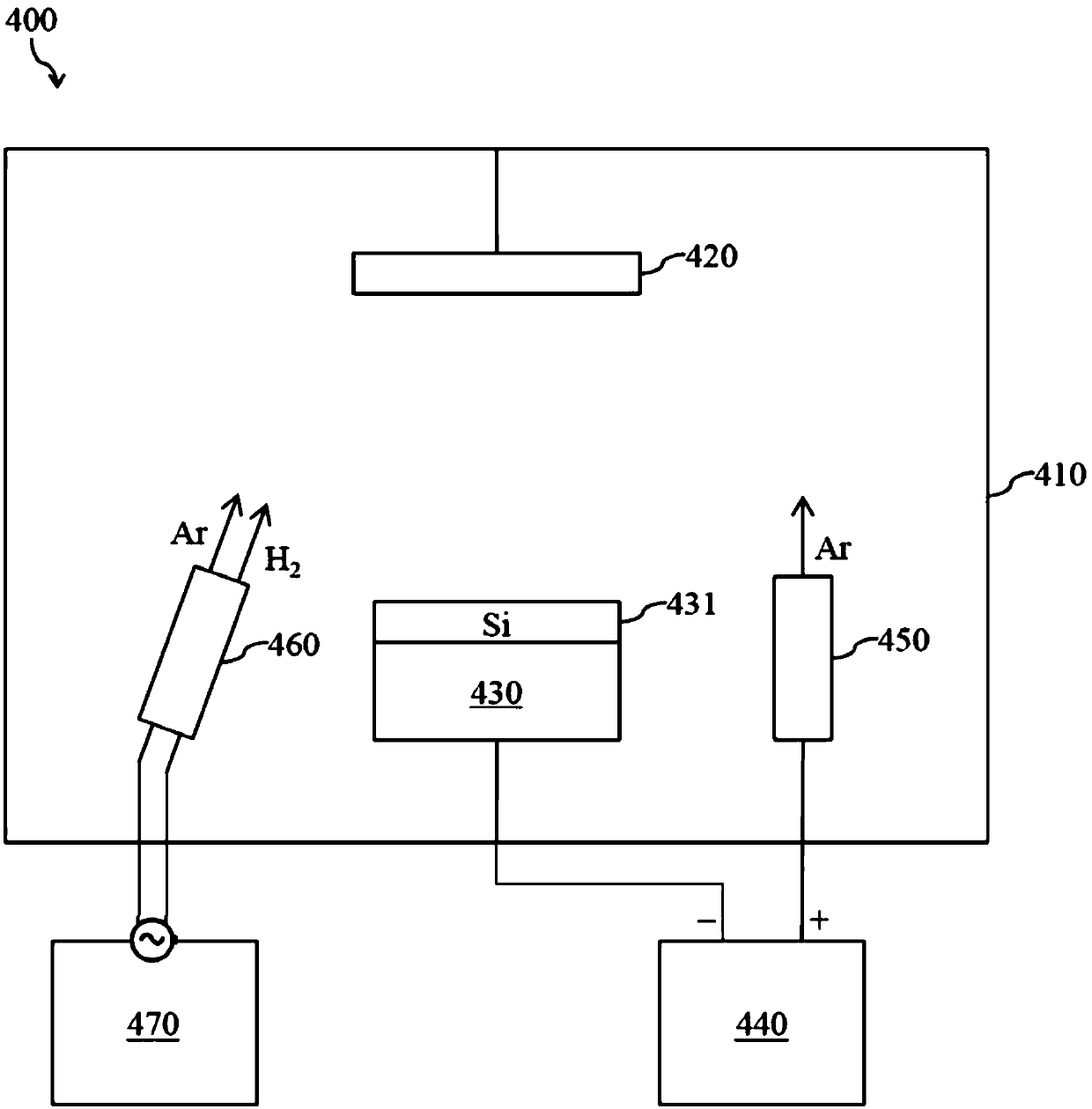

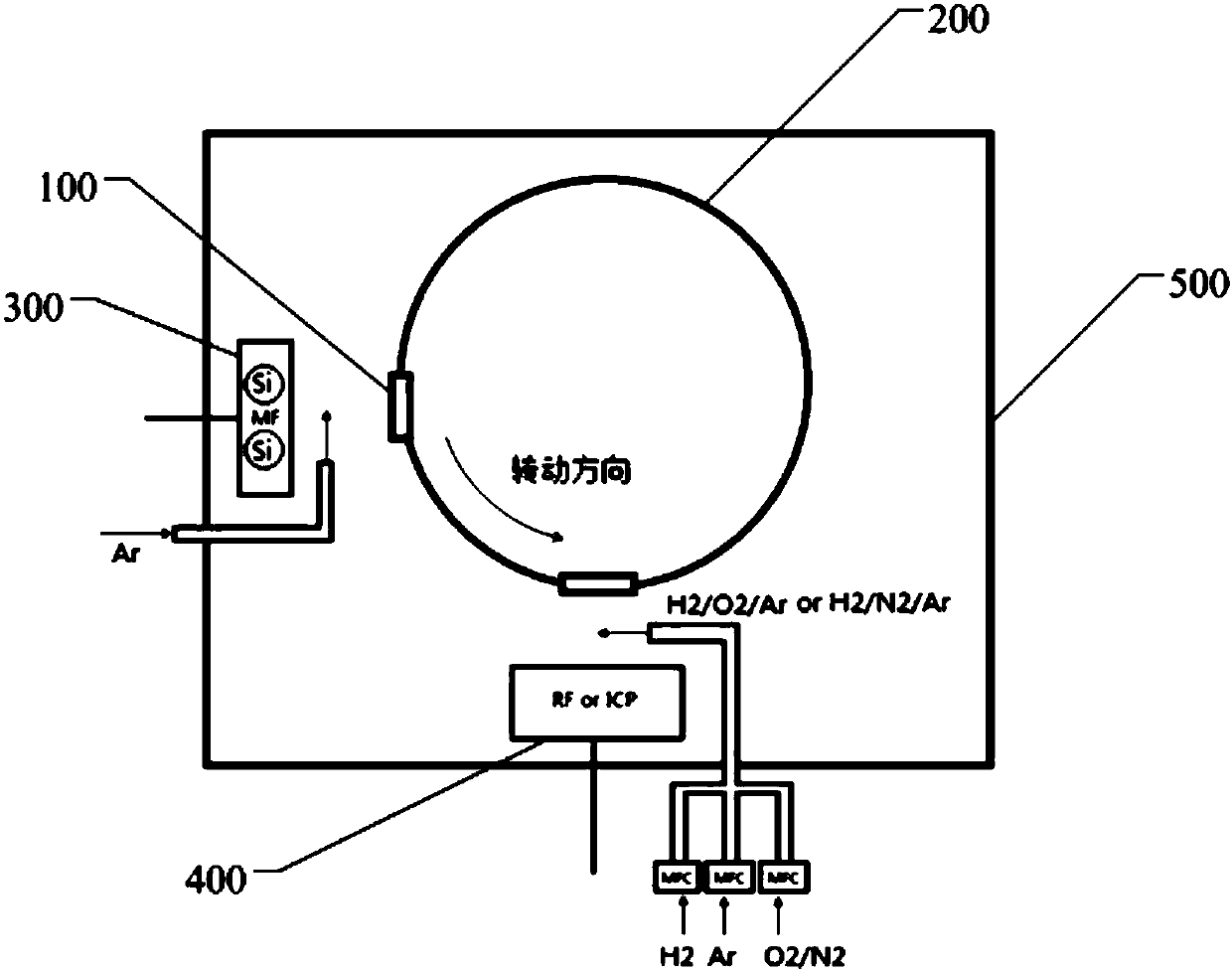

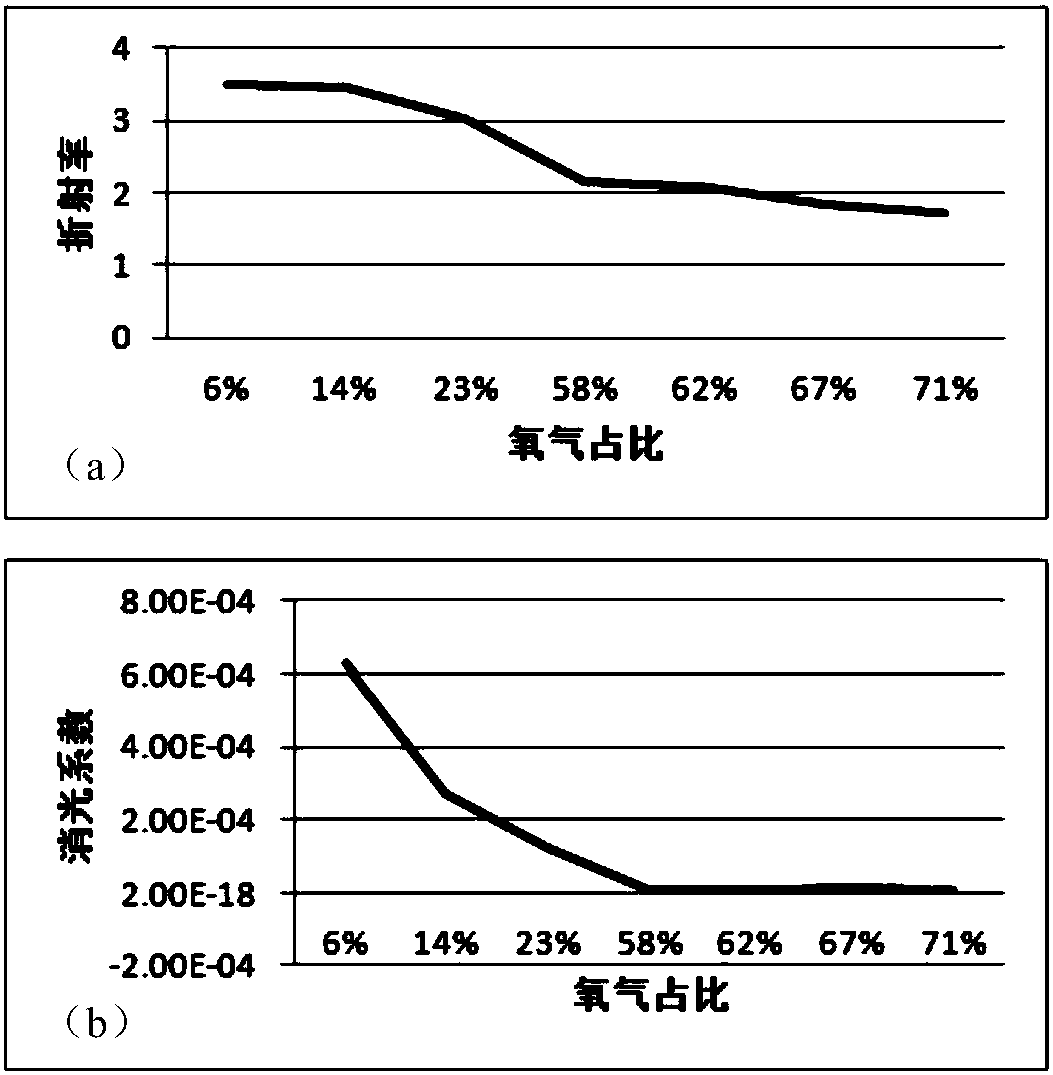

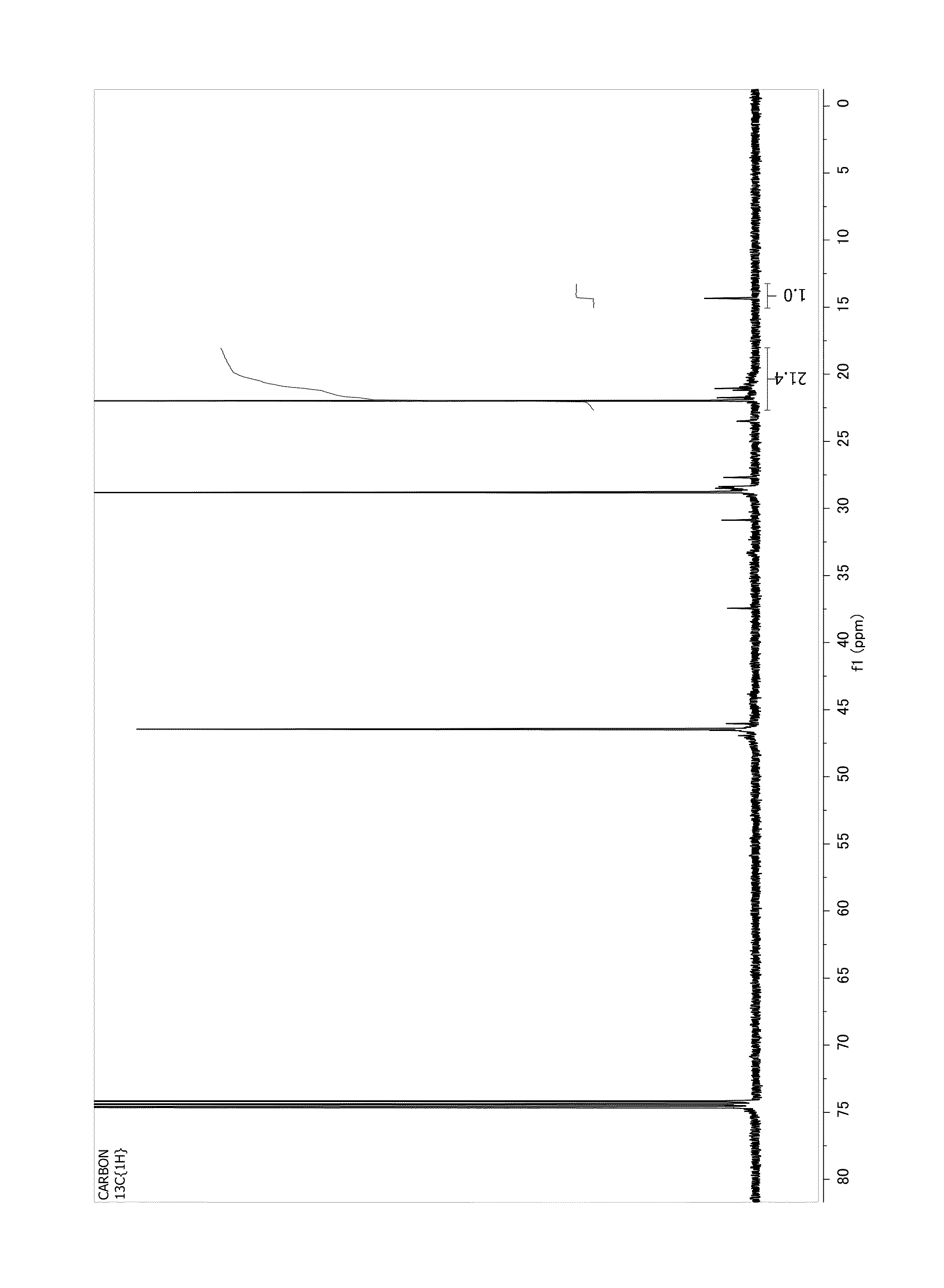

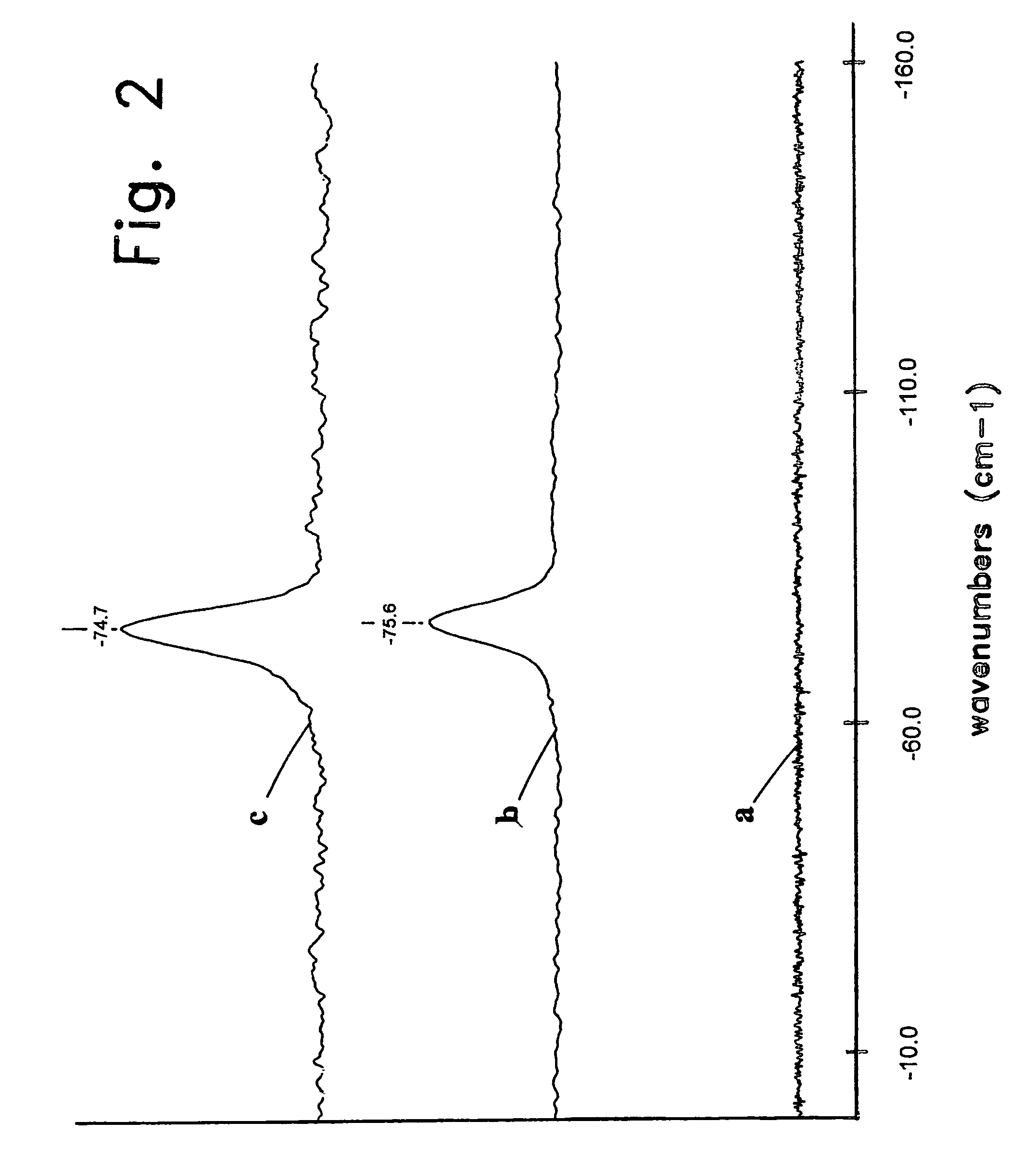

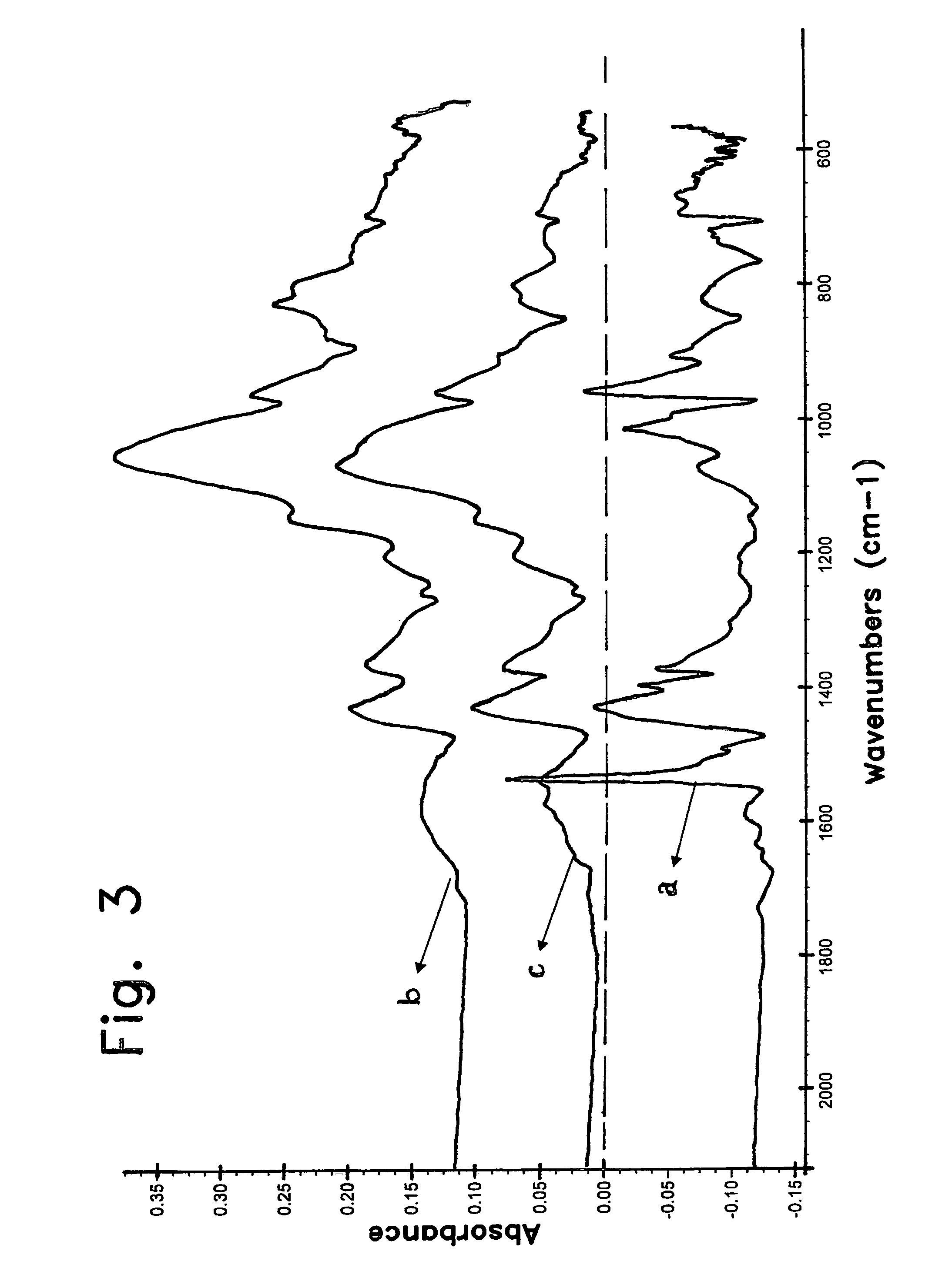

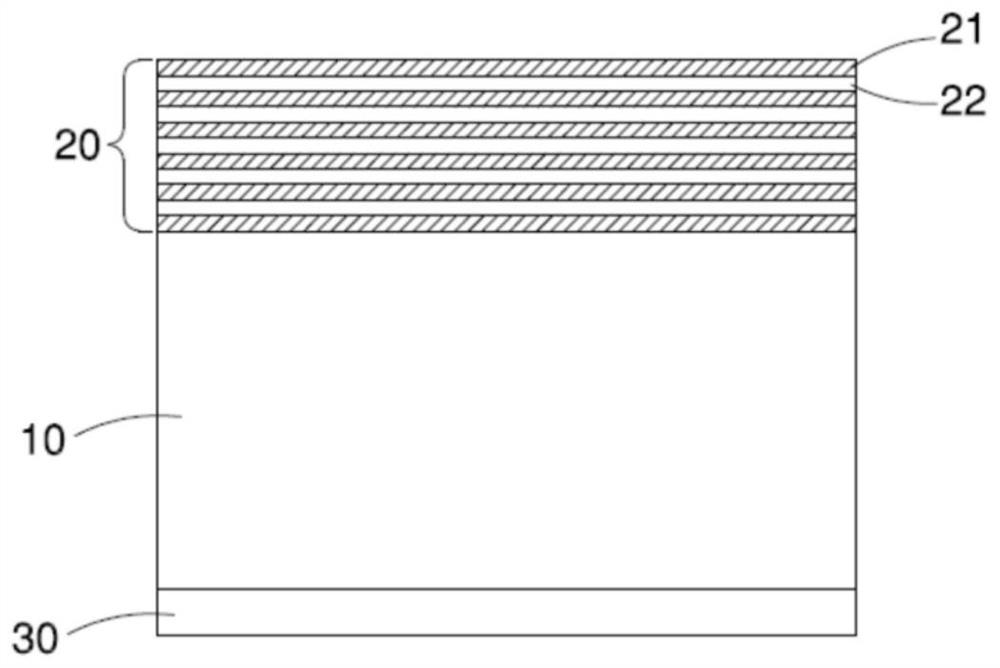

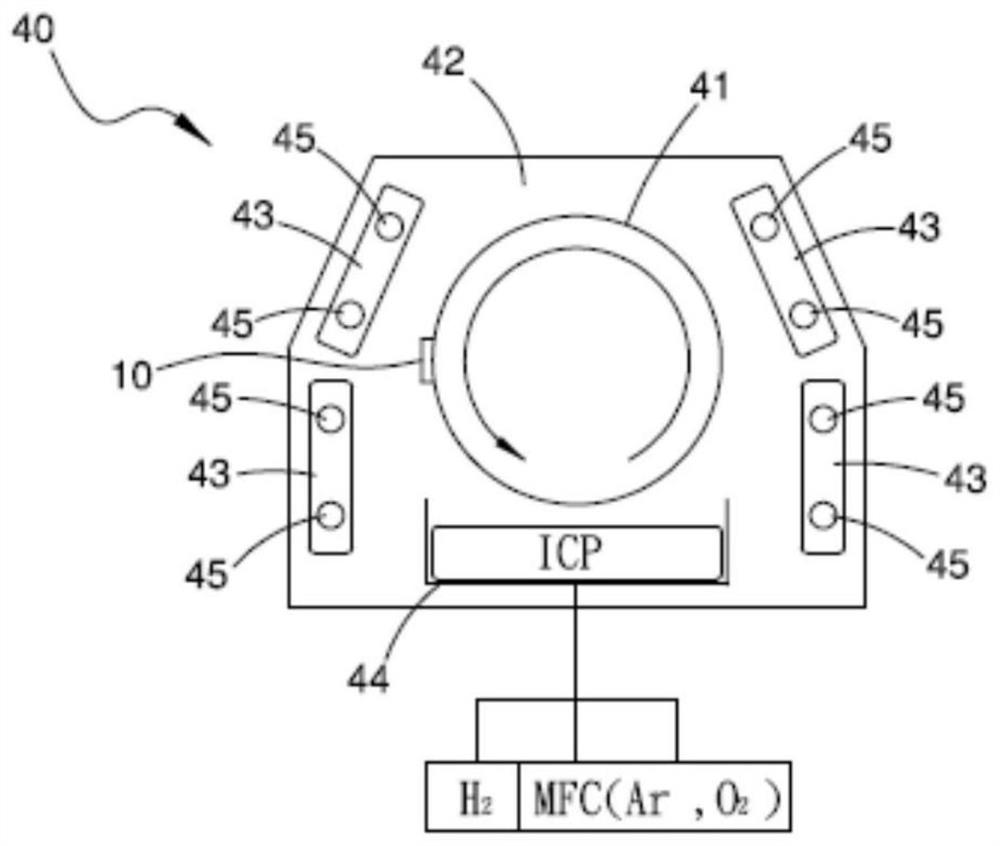

Preparation method for high-refractive index hydrogenated silicon film, high-refractive index hydrogenated silicon film, light filtering lamination and light filtering piece

ActiveCN107841712AHigh refractive indexNot easy to polluteOptical filtersVacuum evaporation coatingSilica hydrideRefractive index

The invention discloses a preparation method for a high-refractive index hydrogenated silicon film, the high-refractive index hydrogenated silicon film, a light filtering lamination and a light filtering piece and relates to the technical field of optical films. The preparation method comprises the following steps that firstly, by means of magnetic controlled Si target sputtering, Si deposits on abase body, and a silicon film is formed; and secondly, the hydrogenated silicon film containing oxygen is formed through the silicon film under the environment where activated hydrogen and active oxygen are contained, the amount of the activated oxygen accounts for 4%-99% of the total amount of the activated hydrogen and the activated oxygen, or, the hydrogenated silicon film containing nitrogenis formed through the silicon film under the environment where the activated hydrogen and the activated nitrogen are contained, and the amount of the activated nitrogen accounts for 5%-20% of the total amount of the activated hydrogen and the activated nitrogen. According to the preparation method, sputtering and a reaction are separately conducted, firstly, by means of magnetic controlled Si target sputtering, Si deposits on the base body, then, plasmas of the activated hydrogen and the activated oxygen / nitrogen react with the silicon to obtain the oxygen or nitrogen containing SiH, the poisoning problem of a target is avoided, and the SiH film has a relatively high refractive index and relatively low absorption.

Owner:ZHEJIANG CRYSTAL OPTECH

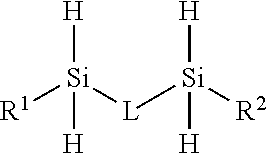

Block copolymers from silylated vinyl terminated macromers

This invention relates to a process to functionalize polyolefins comprising contacting a metallocene catalyst with a difunctional diblock hydrosilane, and one or more vinyl terminated polyolefins. This invention further relates to the diblock hydrosilane-functionalized polyolefins produced thereby.

Owner:EXXONMOBIL CHEM PAT INC

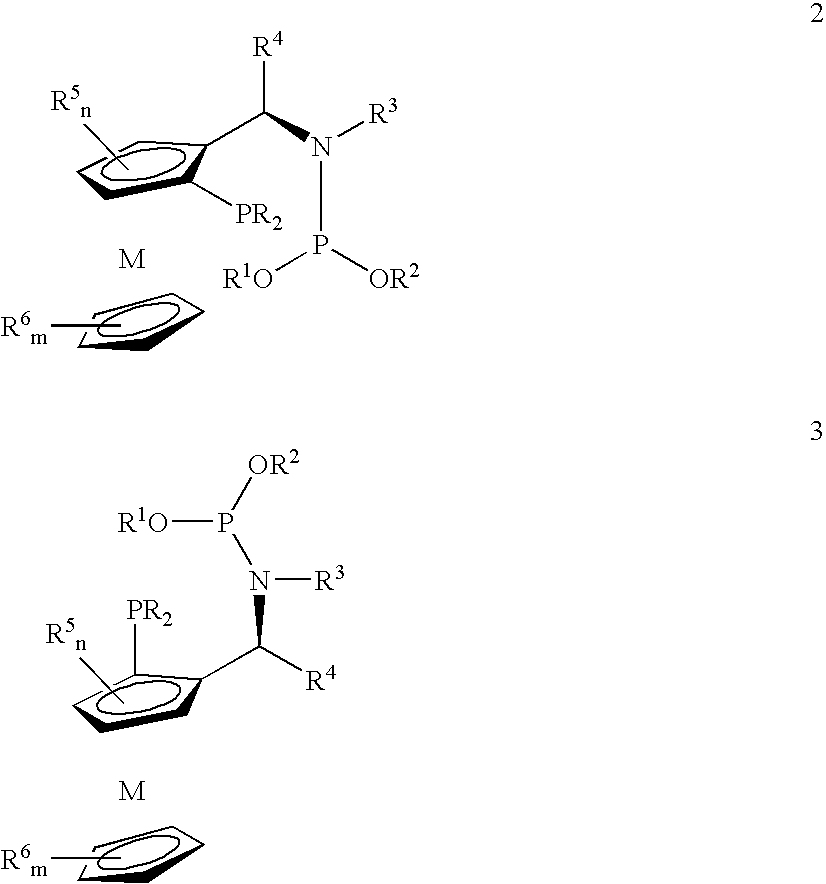

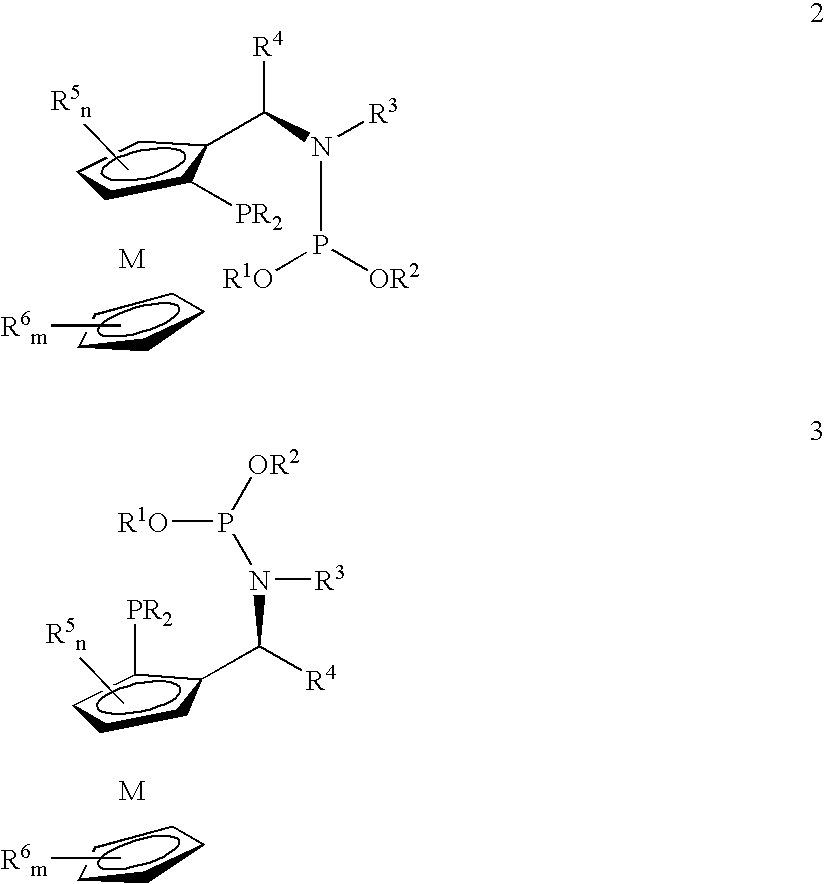

Phosphine-phosphoramidite compounds

ActiveUS6906212B1Hydrocarbon by hydrogenationGroup 8/9/10/18 element organic compoundsIsomerizationSilica hydride

Disclosed are novel phosphine-phosphoramidite compounds which may be employed in combination with a catalytically-active metal to effect a wide variety of reactions such as asymmetric hydrogenations, asymmetric reductions, asymmetric hydroborations, asymmetric olefin isomerizations, asymmetric hydrosilations, asymmetric allylations, asymmetric conjugate additions, and asymmetric organometallic additions. Also disclosed are a process for the preparation of the phosphine-phosphoramidite compounds, metal complex compounds comprising at least one of the phosphine-phosphoramidite compounds and a catalytically-active metal and hydrogenation processes utilizing the metal complex compounds.

Owner:JOHNSON MATTHEY PLC

Curing rubber by hydrosilation

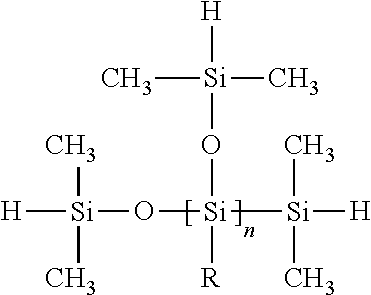

A method for preparing a thermoplastic vulcanizate, the method comprising dynamically vulcanizing a rubber within a blend that includes the rubber and a thermoplastic polymer, where said dynamically vulcanizing is effected with a cure system that includes a hydrosilating agent and a catalyst, where the hydrosilating agent includes a compound including at least 3 silicon hydride groups defined by the formulawhere each R is independently a monovalent organic group or hydrogen, and where the silicon atoms of the respective silicon hydride groups are spatially separated by at least 6 atoms.

Owner:CELANESE INT CORP

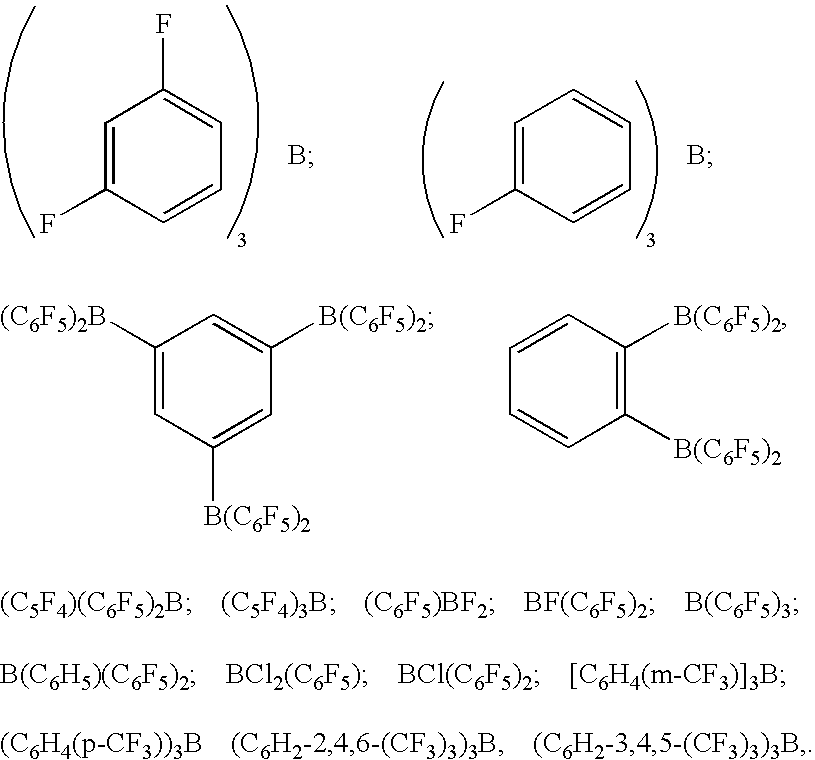

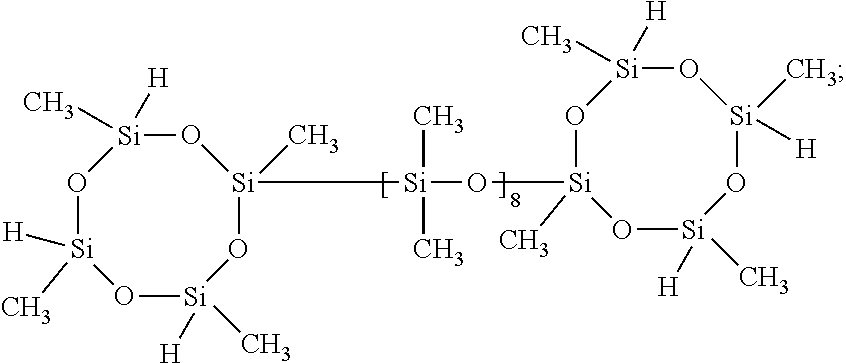

Disproportionation of hydridosiloxanes and crosslinked polysiloxane network derived therefrom

Disclosed is a crosslinked polysiloxane network comprising both residual Si—H linkages and a Lewis acid catalyst, wherein the network is derived from a linear hydridosiloxane, a branched hydridosiloxane, a cyclic hydridosiloxane or a mixture of a linear hydridosiloxane or branched hydridosiloxane and a cyclic hydridosiloxane. Disclosed also is a method to produce the crosslinked polysiloxane network, alternatively accompanied by a silane with aliphatic, aromatic, or cycloaliphatic substituents by reacting in the presence of an effective amount of a Lewis acid catalyst a linear hydridosiloxane, a branched hydridosiloxane, a cyclic hydridosiloxane or a mixture of a linear hydridosiloxane or branched hydridosiloxane and a cyclic hydridosiloxane.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

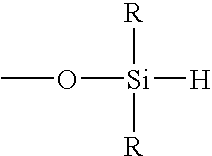

Process for making siloxane oligomer

A process for making a Si—H functional siloxane oligomer from the reaction between silicon hydride compositions and cyclic siloxane oligomer in the presence of a Lewis acid is provided. The Lewis acid is operable to interact with the hydrogen of the silicon hydride to promote ring opening of the cyclic siloxane oligomer and the insertion a siloxane oligomer segment between Si and H atom to thereby form the Si—H functional siloxane oligomer.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Silicon-Germanium Hydrides and Methods for Making and Using Same

InactiveUS20090050935A1Liquid surface applicatorsLayered productsSemiconductor structureMedicinal chemistry

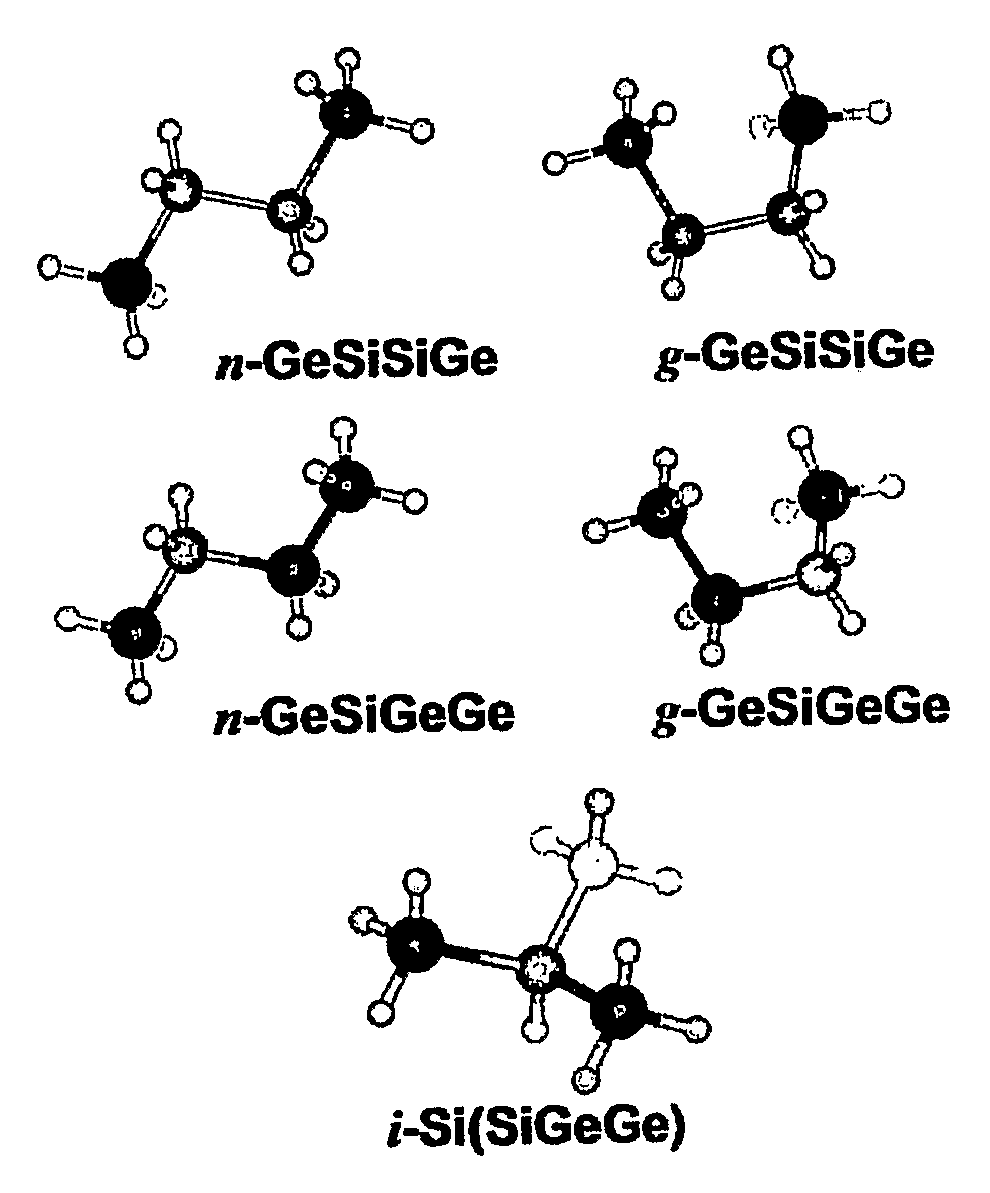

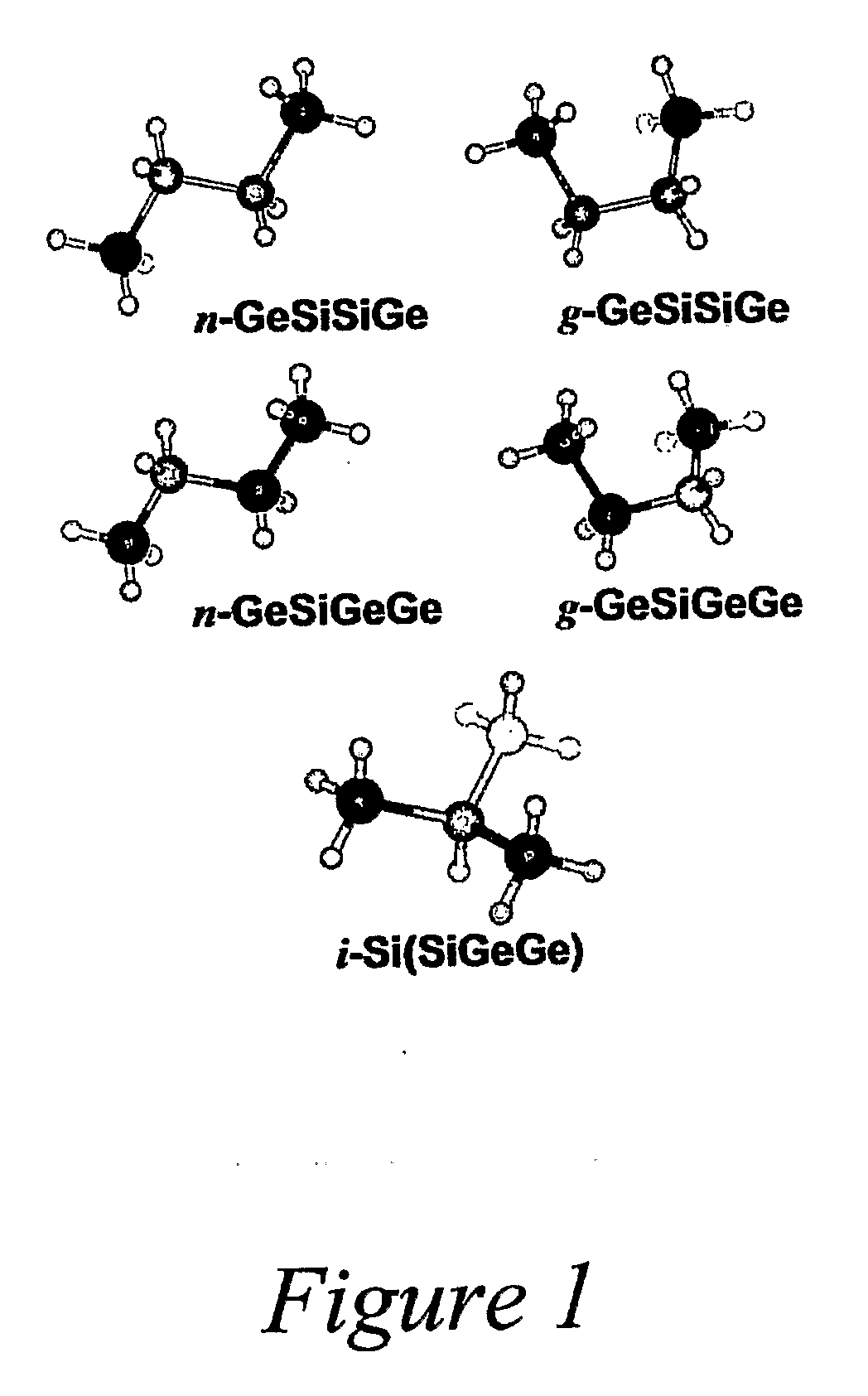

The present invention provides silicon-germanium hydride compounds, methods for their synthesis, methods for their deposition, and semiconductor structures made using the compounds. The compounds are defined by formula: SiHnI (GeHn2)y, wherein y is 2, 3, or 4 wherein n1 is 0 1, 2 or 3 to satisfy valency and wherein n2 is independently 0, 1, 2 or 3 for each Ge atom in the compound, to satisfy valency.

Owner:ARIZONA STATE UNIVERSITY

Polysiloxane composition, molded body obtained from the same, and optodevice member

ActiveUS8299198B2Impart resistanceImpart retardancyRecord information storageOptical recording/reproducingPolymer sciencePtru catalyst

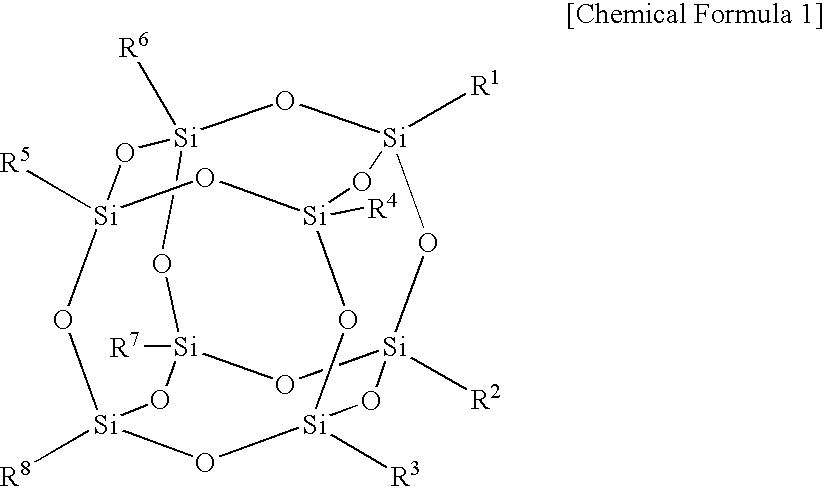

The present invention provides a polysiloxane composition maintaining high transparency over a wide wavelength region and a wide temperature region and being excellent in heat resistance, low-dielectric characteristics, workability, and the like. A polysiloxane composition includes (A) a polysiloxane which is composed of a polysiloxane compound having a polyhedral skeleton having 6 to 24 Si atoms in its molecule and which has at least one alkenyl group bonded directly or indirectly to a Si atom constituting the polyhedral skeleton, (B) a polysiloxane having a hydrosilyl group, and (C) a hydrosilylation catalyst.

Owner:KANEKA CORP

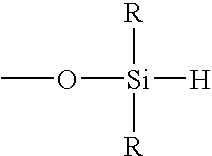

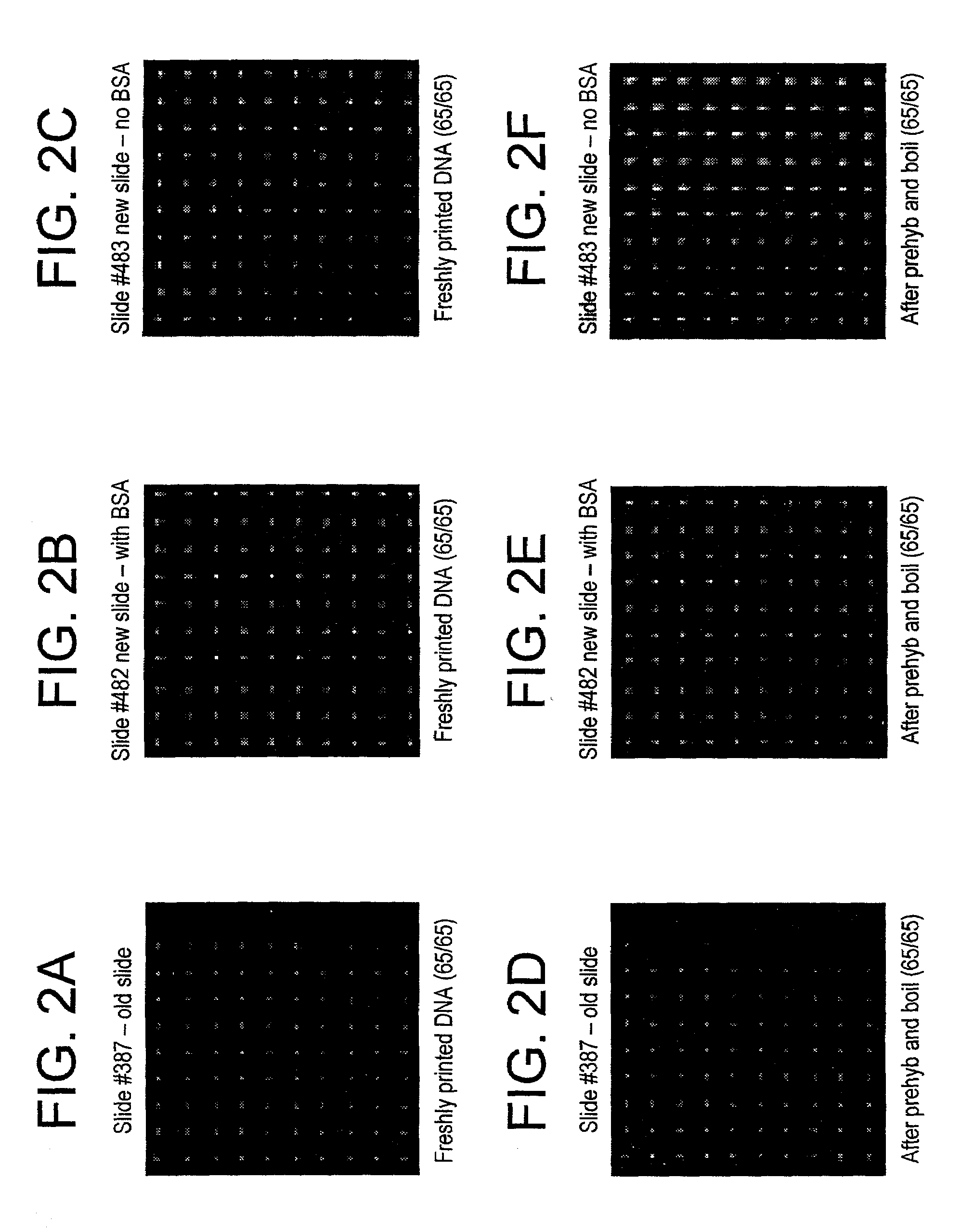

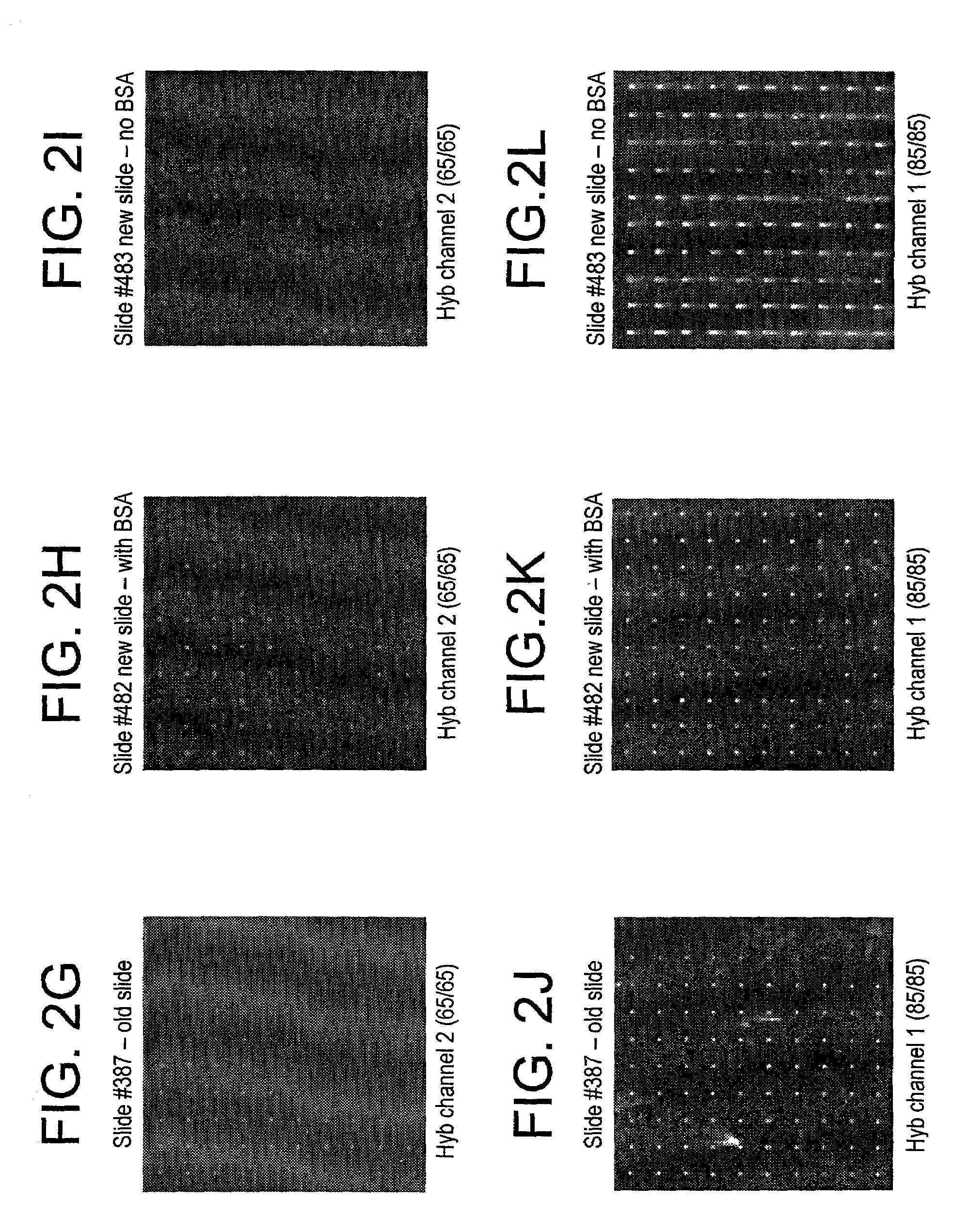

Reagent and method for attaching target molecules to a surface

InactiveUS7217512B2Bioreactor/fermenter combinationsBiological substance pretreatmentsMicroscope slidePlastic materials

The present invention provides a method and reagent composition for attachment of target molecules onto the surface of a substrate, such as microwell plates, tubes, beads, microscope slides, silicon wafers or membranes. In one embodiment, the method and composition are used to immobilize nucleic acid probes onto plastic materials such as microwell plates, e.g., for use in hybridization assays. In a preferred embodiment, the method and composition are adapted for use with substantially flat surfaces, such as those provided by microscope slides and other plastic, silicon hydride, or organosilane-pretreated glass or silicone slide support surfaces. The reagent composition can then be used to attach a target molecule such as a biomolecule (e.g., a nucleic acid) which in turn can be used for specific binding reactions (e.g., to hybridize a nucleic acid to its complementary strand).

Owner:CORNING INC

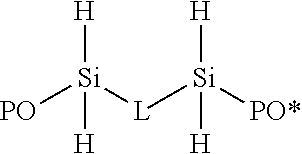

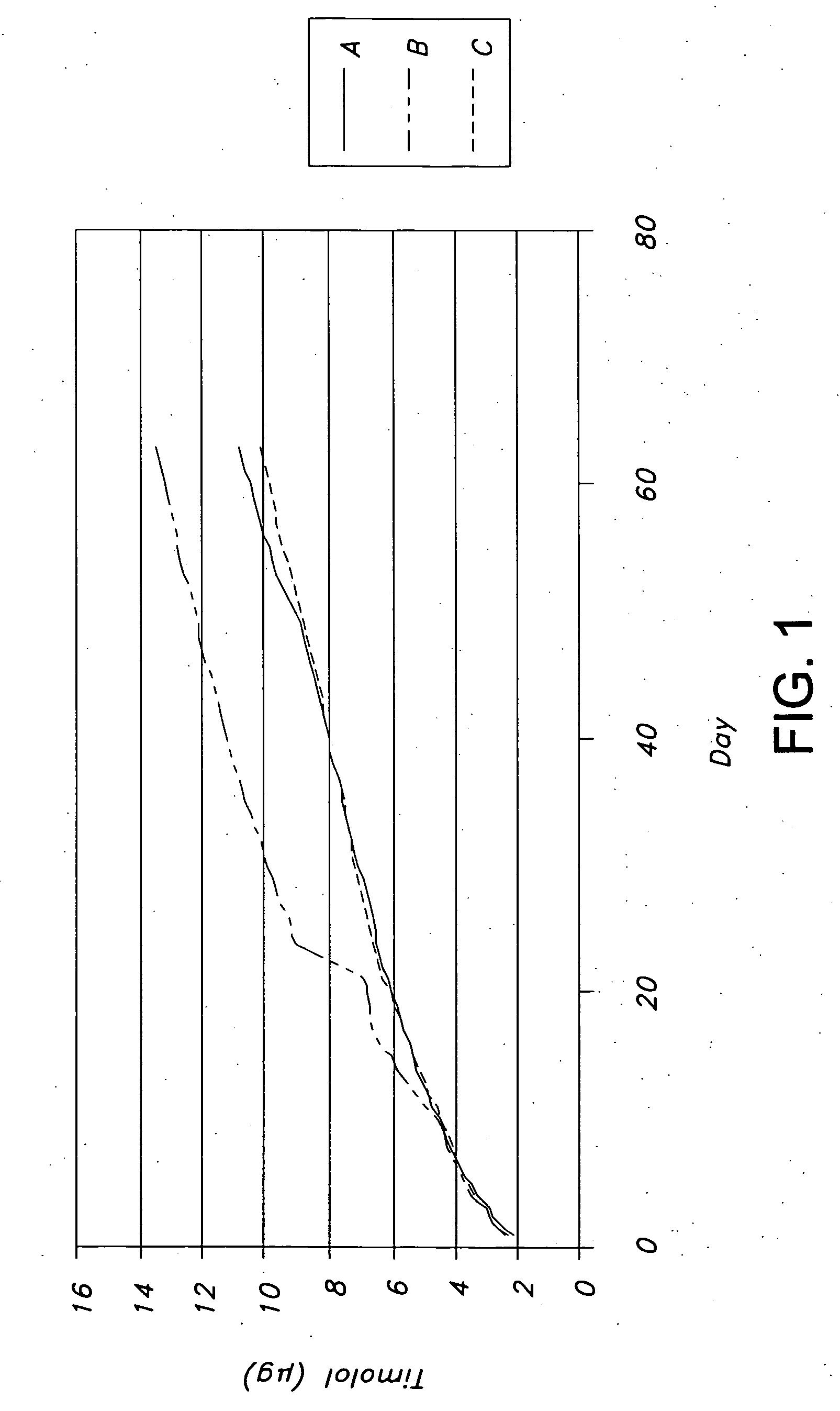

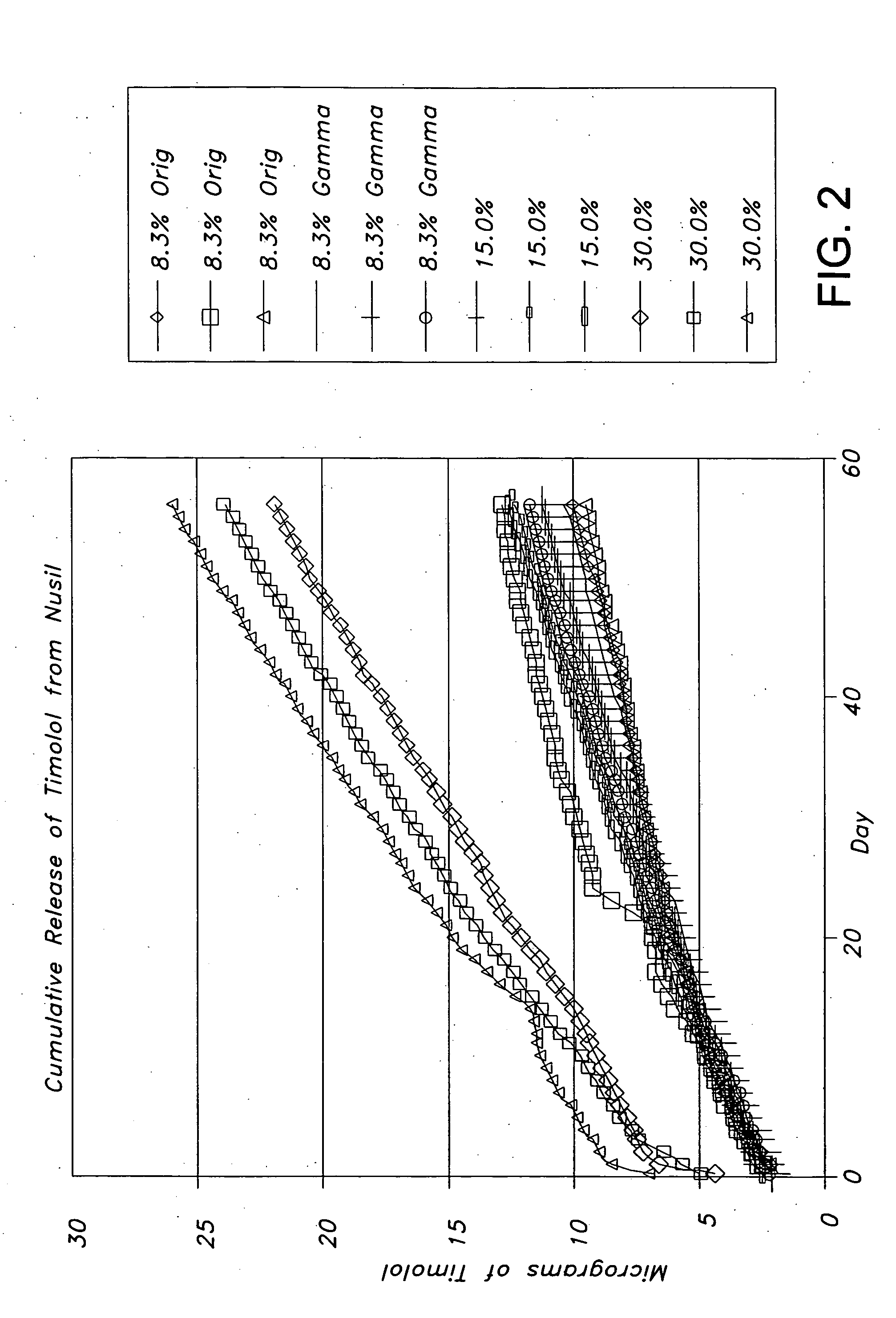

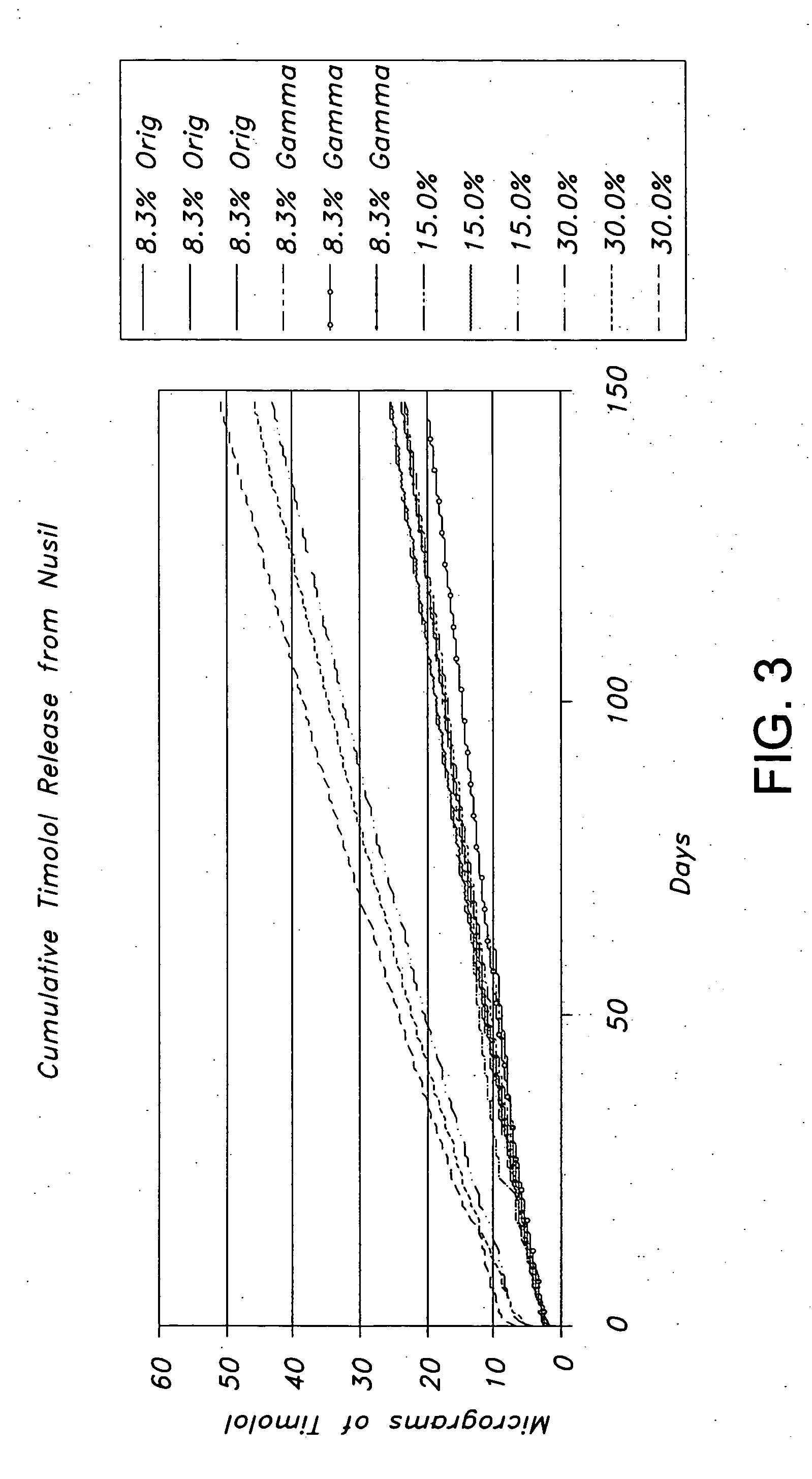

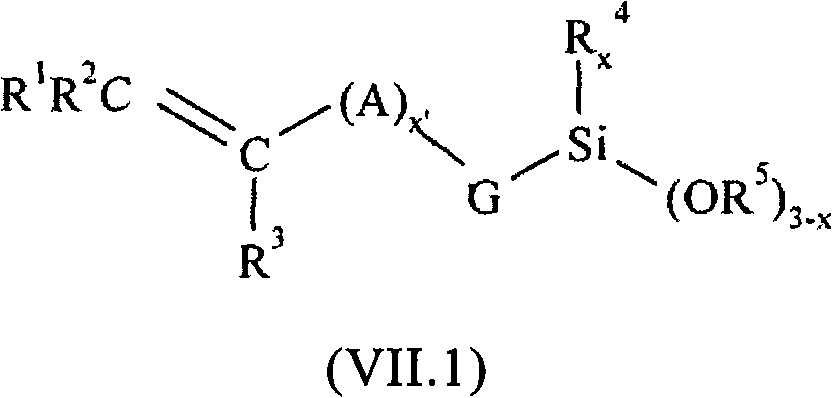

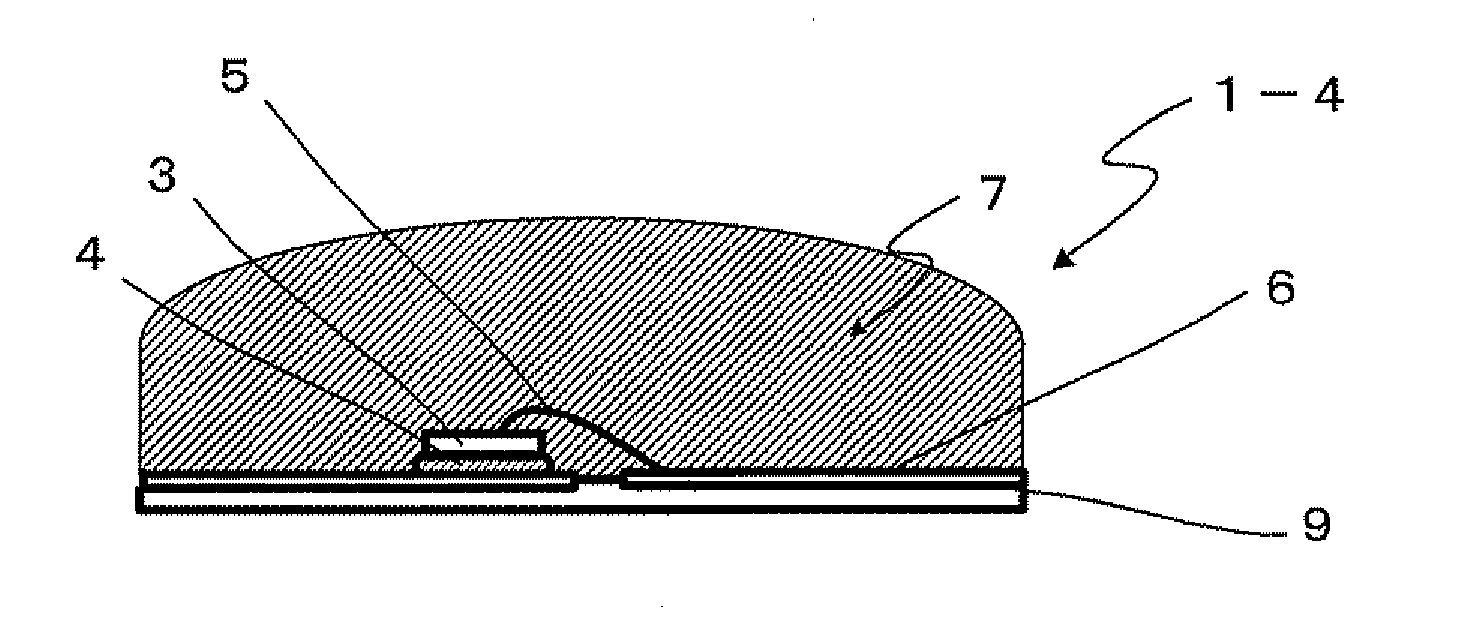

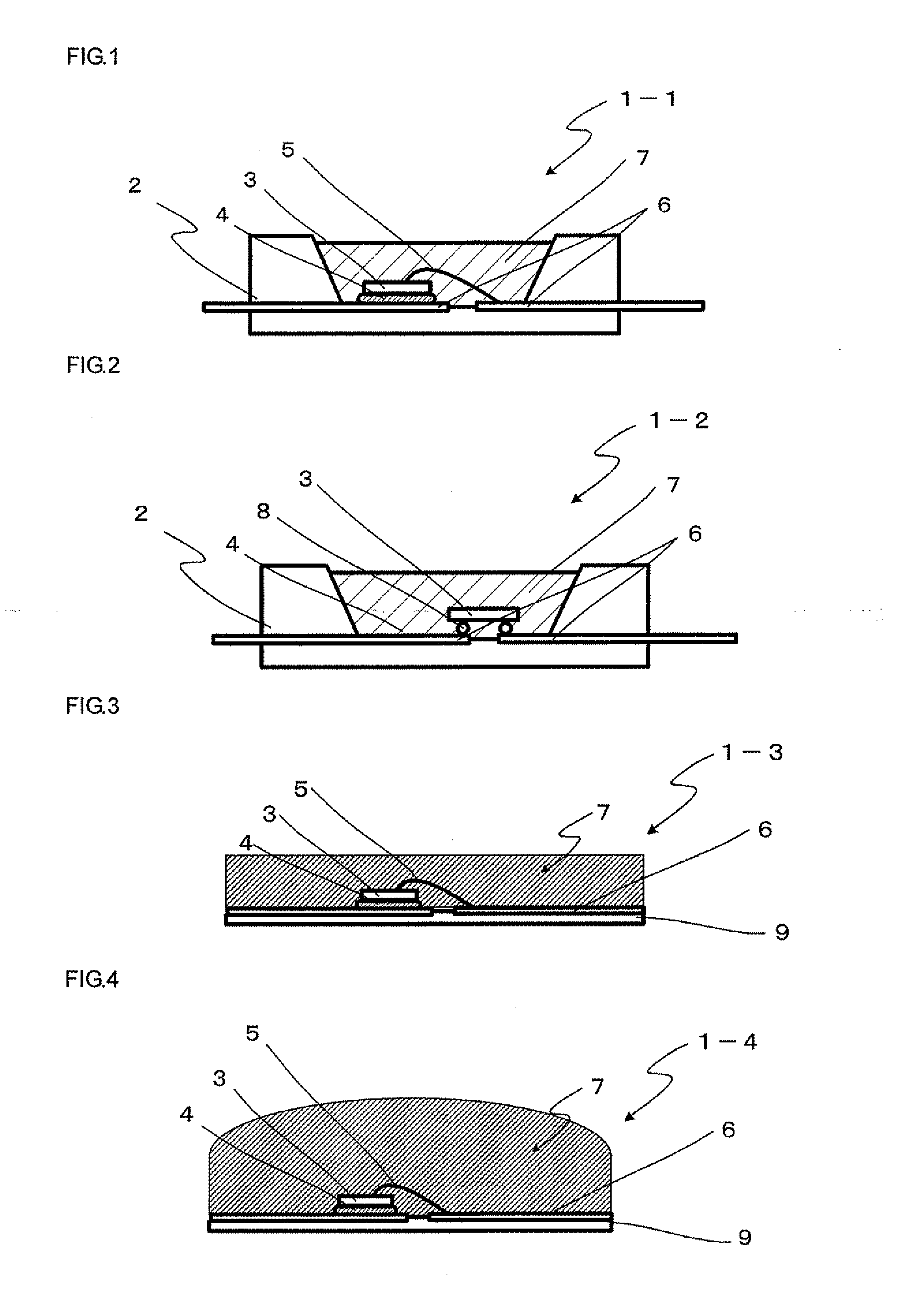

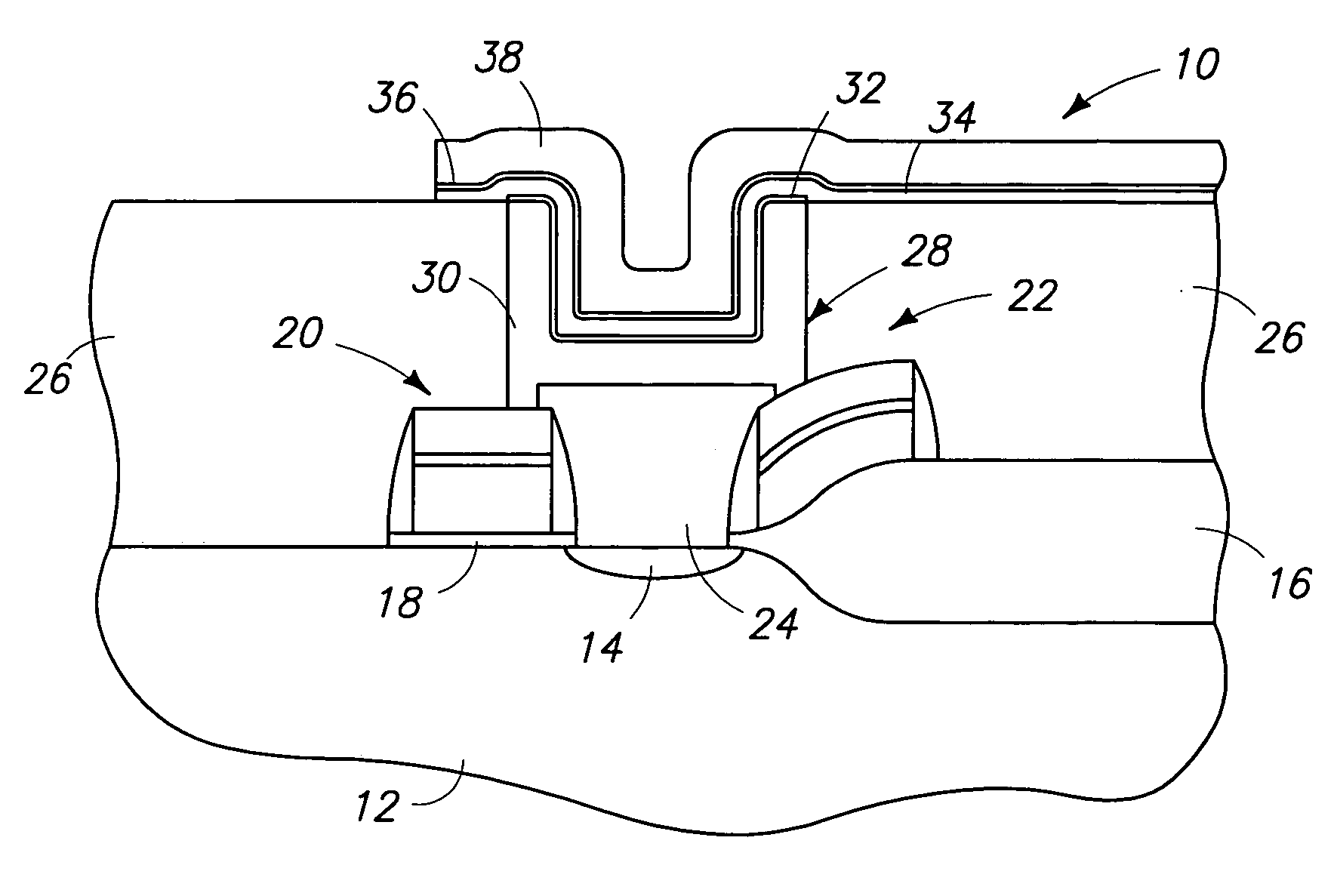

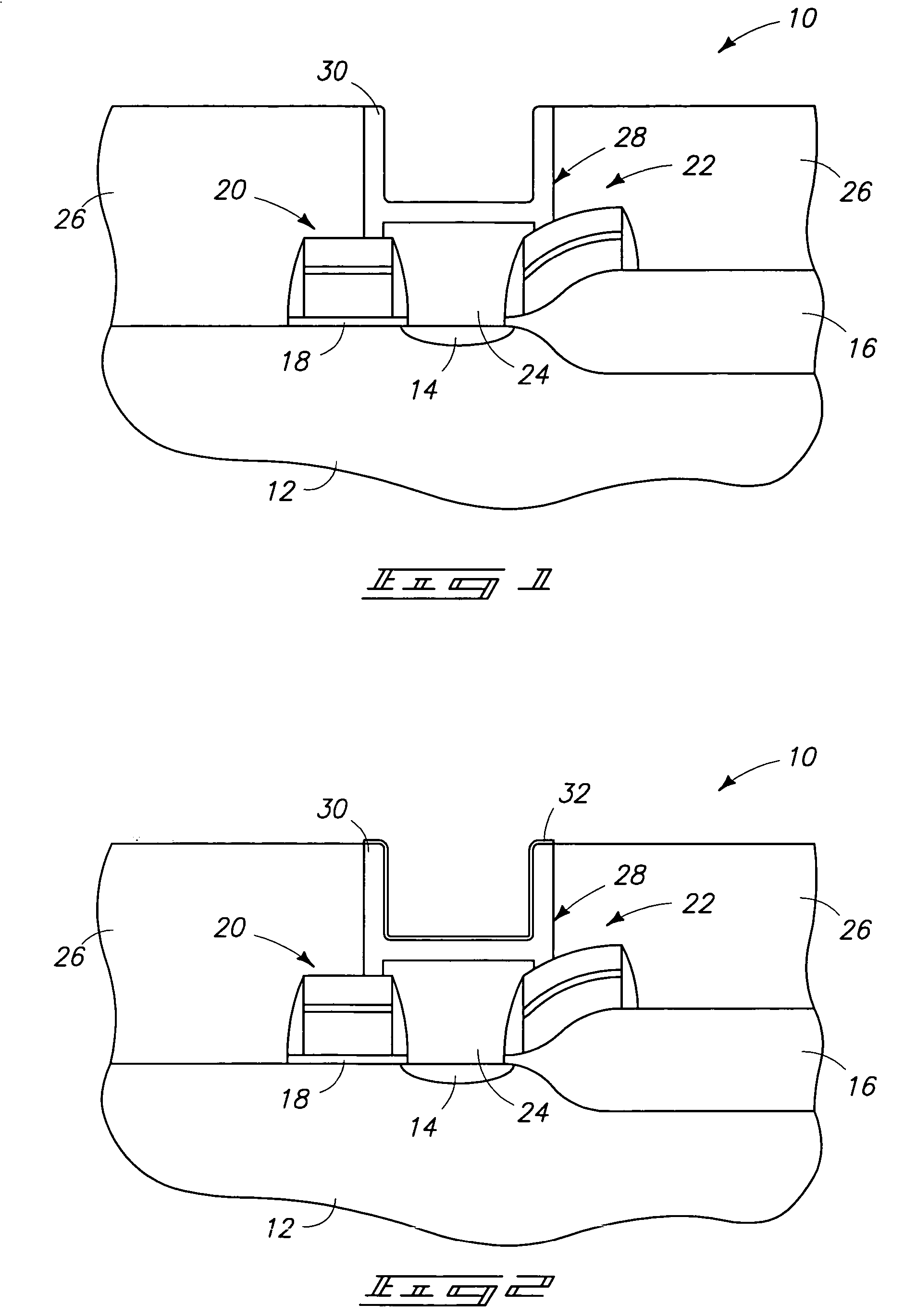

Drug delivery systems

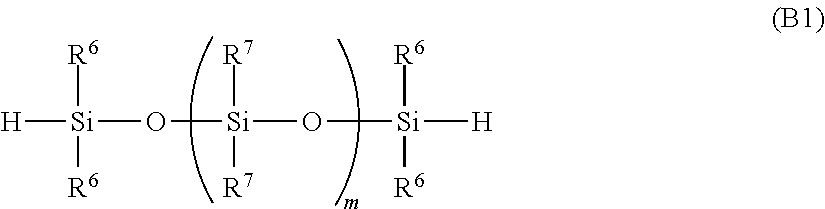

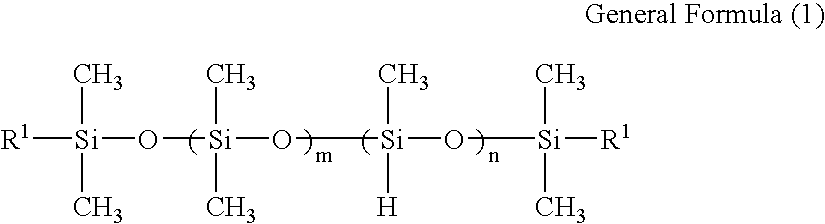

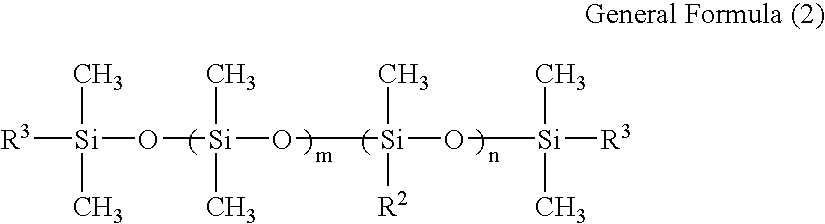

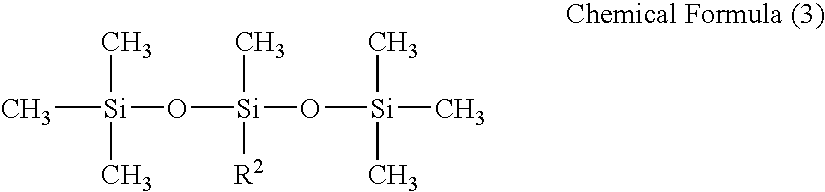

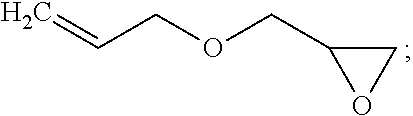

Matrix controlled diffusion drug delivery systems based on polymerization products of monomeric mixture comprising (a) one or more silicone-containing monomers of the general formula: wherein x, y, m, m′, R, R1, R2, R3, R4, R5, R6, R7, X, Z and Z′ are as defined herein and (b) silicon hydride-containing monomers are provided, wherein the matrix controlled diffusion drug delivery systems are sized and configured for back of the eye delivery.

Owner:BAUSCH & LOMB INC

Adhesive silicone elastomer composition

The present invention relates to a high-performance silicone elastomer composition that is adhesive and that can be crosslinked at high temperature for the assembly of silicone-based substrates, both by platinum and peroxide catalysis, and that may lend itself to a strip conformation. The composition comprises at least one gum, one catalyst and one adhesion promoter of polyorganohydrogensiloxane type, the nature and the amount of said adhesion promoter having been chosen so that Si-H groups are in excess following the reaction for crosslinking the composition, so as to obtain a potential surface density of covalent Si- bonds with the silicone substrate to be bonded of at least one covalent Si- bond per 60 nm2.

Owner:BLUESTAR SILICONES FRANCE SAS

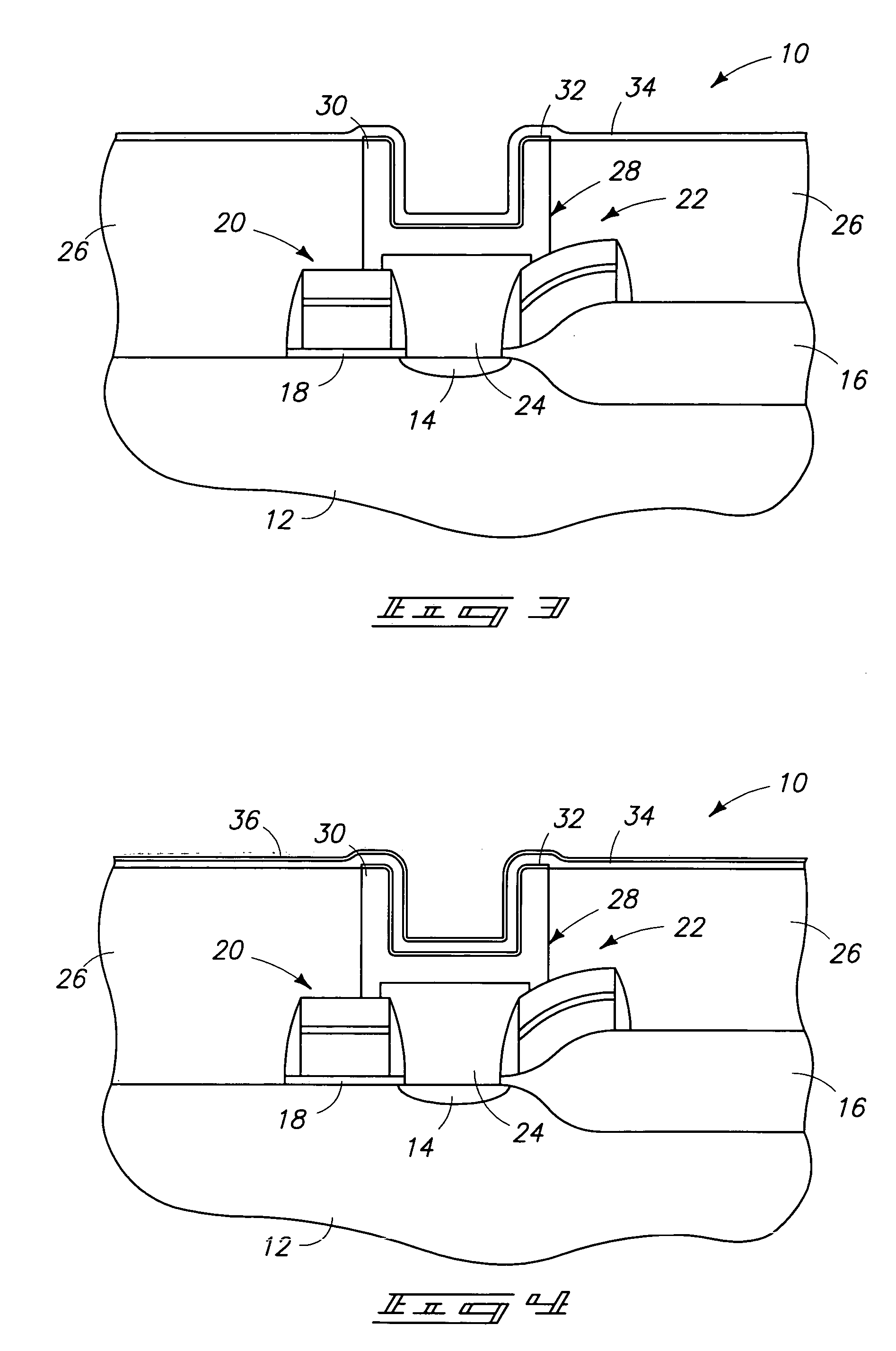

Optical semiconductor device

ActiveUS20130056786A1Prevent discolorationIncreased durabilitySolid-state devicesSemiconductor devicesArylSilylene

An optical semiconductor device in which an optical semiconductor element connected to a silver-plated copper lead frame is sealed with an addition curing silicone resin composition, the addition curing silicone resin composition having (A) organopolysiloxane that contains an aryl group and an alkenyl group and does not contain an epoxy group; (B) organohydrogenpolysiloxane that has at least two hydrosilyl groups per molecule and an aryl group, the organohydrogenpolysiloxane that contains 30 mol % or more of an HR2SiO0.5 unit in a constituent unit having an amount that a molar ratio of the hydrosilyl group in the component (B) with respect to the alkenyl group in the component (A) is 0.70 to 1.00; and (C) a hydrosilylation catalyst having a catalytic amount.

Owner:SHIN ETSU CHEM IND CO LTD

High-Temperature Ionic State Compound Crystallization Technology

InactiveUS20100320075A1High purityIncrease productionVacuum evaporation coatingSputtering coatingHigh pressureHigh voltage

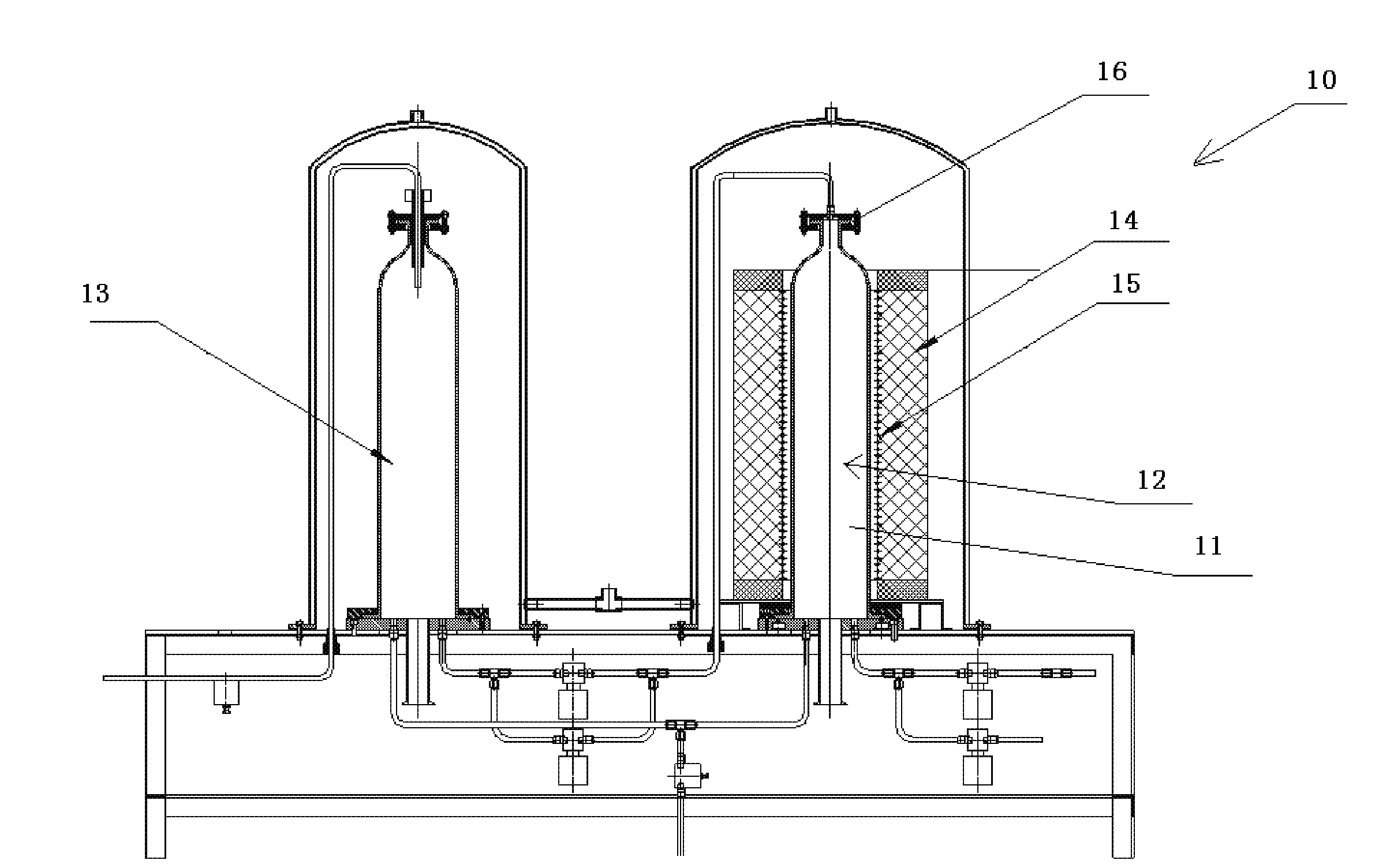

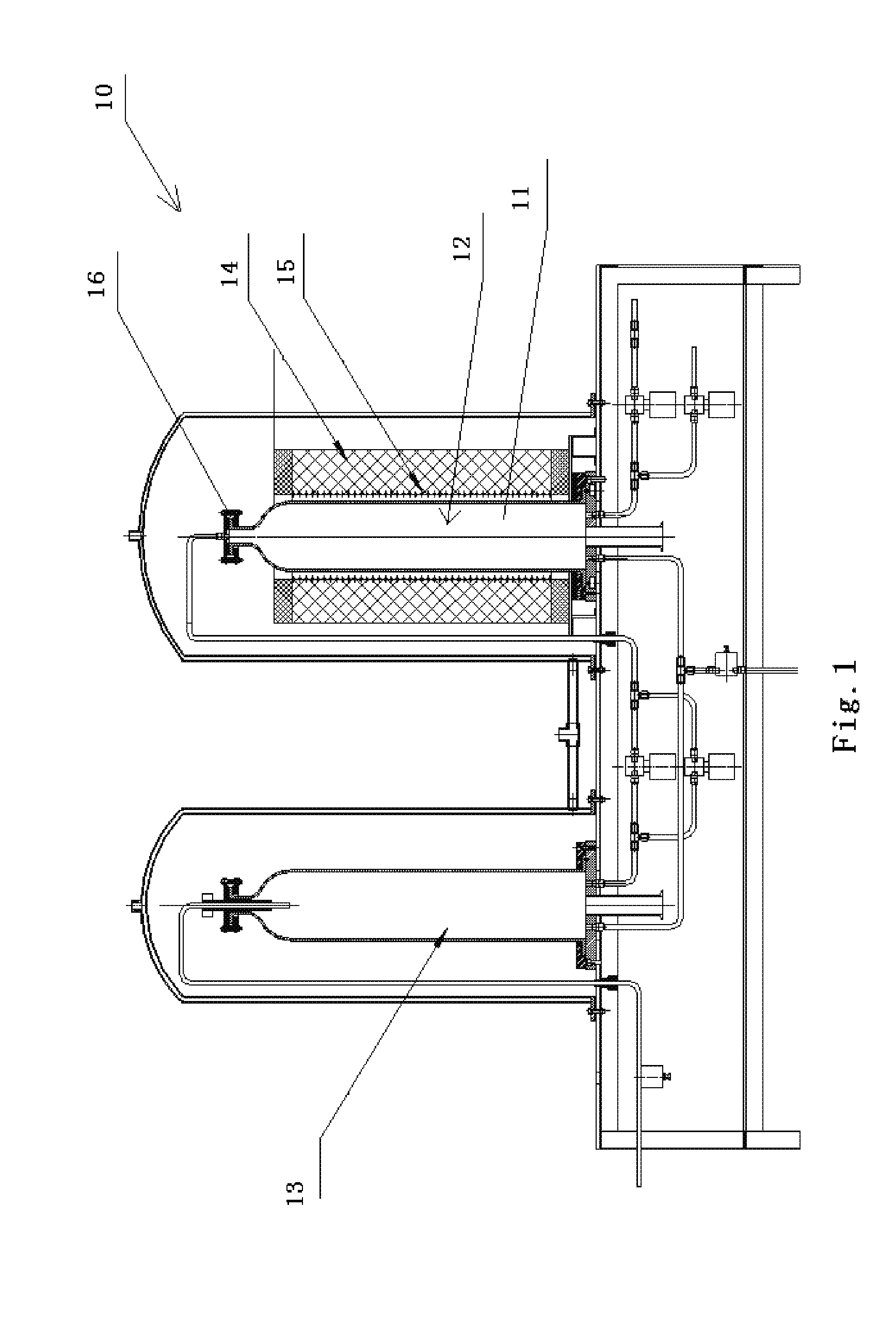

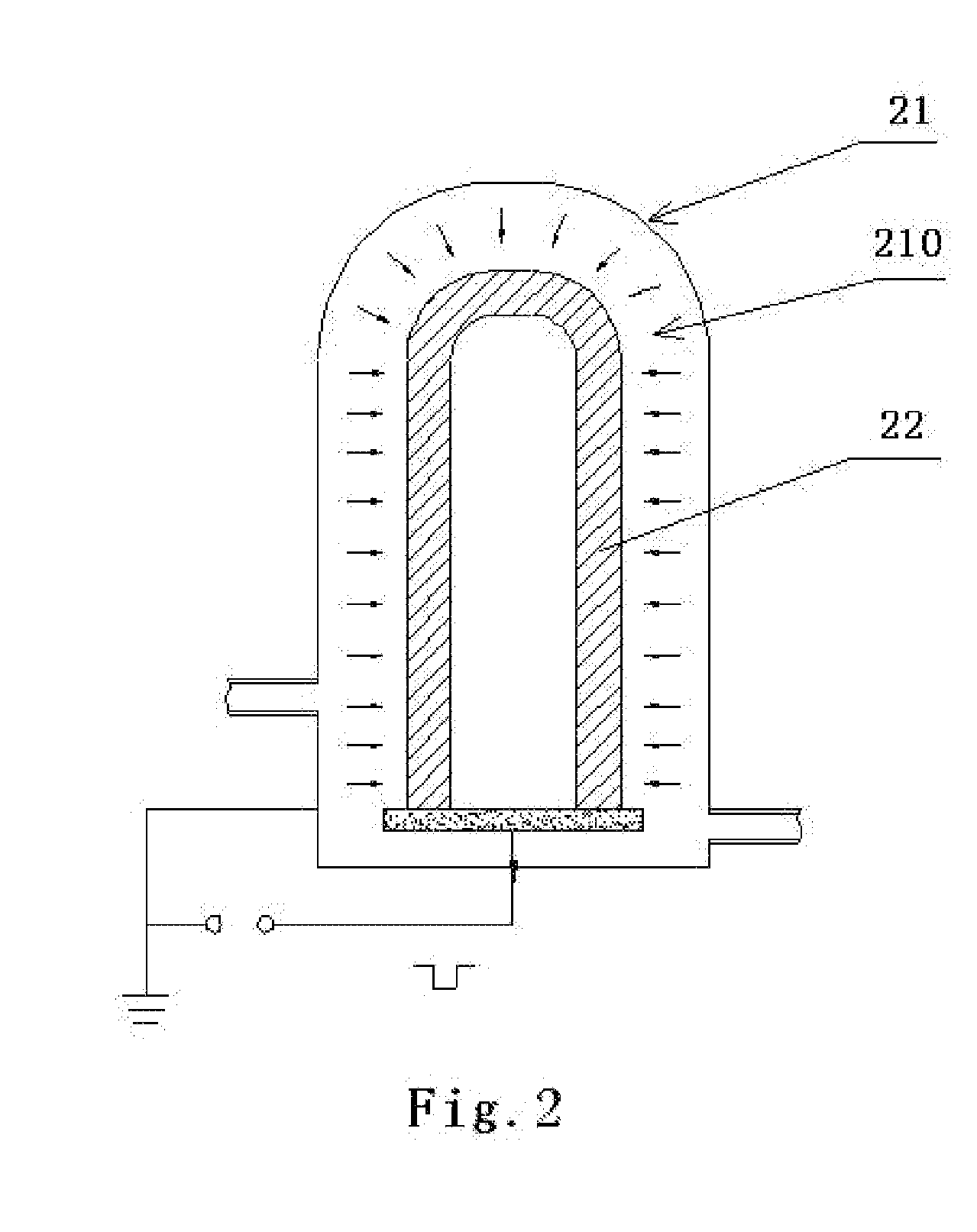

The present invention provides a high-temperature ionic state fluidized bed compound crystallization technology and an internal reactor structure thereof. The principle of the present invention is that reaction gas is effected by a group of high-frequency external magnetic fields and forms the high-temperature gaseous ion in the first quartz vacuum tube, then forms ion deposition diffusion in the second quartz vacuum tube preheated at constant temperature. As a result, other high-temperature gaseous ions except the silicon hydride are decomposed, rapidly deposited and crystallized in the ion diffusion chamber. And the un-decomposed silicon hydride gas is directly poured into the surface of the silicon heating body of the compound fluidized bed by the static negative high-voltage quartz spray hole to decompose and crystallize, or crystallize by a way of fluid state in the arched heating quartz tube communicating with the top of two quartz reaction furnaces.

Owner:WANG HAIBIAO +2

Synthesis of siloxane resins

InactiveUS20050003215A1High yieldGood coating performanceLayered productsThin material handlingAlcoholSilanes

Novel processes for preparing hydridosiloxane and organohydridosiloxane resins are disclosed. The processes of the invention broadly provide for the steps of contacting a silane monomer with a phase transfer catalyst in the presence of a reaction mixture that includes a nonpolar, e.g., hydrocarbon, solvent, and a polar solvent, e.g., alcohol and water. The process is conducted under conditions effective to catalytically convert said silane monomer into hydridosiloxane and organohydridosiloxane resins. Recovery of the products is advantageously aided by the ease of separating the phase transfer catalyst from the dual phase reaction mixture by separating the immiscible polar solvent carrying the catalyst from the nonpolar solvent that carries the product. Hydridosiloxane and organohydridosiloxane resins produced by the processes of the invention are also provided.

Owner:HACKER NIGEL +2

Thermoplastic silicone polyamide elastomers made of nylon resin

A method for preparing a thermoplastic elastomer is disclosed, said method comprising (I) mixing(A) a rheologically stable polyamide resin having a melting point or glass transition temperature of 25° C. to 275° C.,(B) a silicone base comprising(B') 100 parts by weight of a diorganopolysiloxane gum having a plasticity of at least 30 and having an average of at least 2 alkenyl radicals in its molecule and(B'') 5 to 200 parts by weight of a reinforcing filler,the weight ratio of said silicone base to said polyamide resin is from 35:65 to 85:15,(C) 0.01 to 5 parts by weight of a stabilizer per 100 parts by weight of said polyamide resin plus said silicone base, said stabilizer being selected from hindered phenols; thioesters; hindered amines; 2,2'-(1,4-phenylene)bis(4H-3,1-benzoxazin-4-one); and 3,5-di-tert-butyl-4-hydroxybenzoic acid, hexadecyl ester,(D) an organohydrido silicon compound which contains an average of at least 2 silicon-bonded hydrogen groups in its molecule and(E) a hydrosilation catalyst,components (D) and (E) being present in an amount sufficient to cure said diorganopolysiloxane (B'); and(II) dynamically curing said diorganopolysiloxane (B'),wherein at least one property of the thermoplastic elastomer selected from tensile strength or elongation is at least 25% greater than the respective property for a corresponding simple blend wherein said diorganopolysiloxane is not cured and said thermoplastic elastomer has an elongation of at least 25%.

Owner:DOW CORNING CORP +1

Dietary supplement

Owner:RBC LIFE SCI

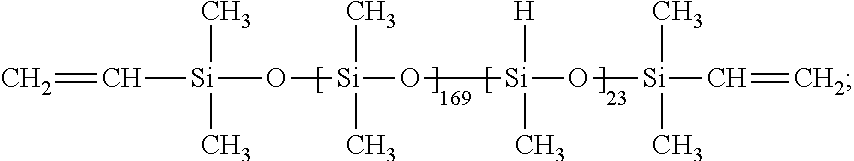

Method of manufacturing purified products of liquid medium-chain alkyl-modified polydimethysiloxane and cosmetics prepared therefrom

A method of manufacturing a purified product of a liquid medium-chain alkyl-modified polydimethylsiloxane that is free of a specific (unpleasant) odor and is practically odorless, the method comprising the steps of: [A] synthesizing a liquid medium-chain alkyl-modified polydimethylsiloxane by carrying out a hydrosilylation reaction between a hydrosilyl-containing polydimethylsiloxane and an α-olefin with 4 to 18 carbon atoms; and [B] subjecting a crude product of the liquid medium-chain alkyl-modified polydimethylsiloxane obtained in preceding step [A] to an odor-removing treatment by conducting a hydrogenation reaction which is carried out in the presence of a hydrogenation catalyst.

Owner:DOW TORAY CO LTD

Preparation method of silica gel sealing medium partition plate

The invention discloses a preparation method of a silica gel sealing medium partition plate, relating to a preparation method of a heat-resistant sealing gasket. The silica gel sealing medium partition plate comprises the following raw material components in parts by weight: 100 parts of dimethyl siloxane and vinyl siloxane polymers, 50 parts of special white carbon black for silicon rubber, 2 parts of zinc oxide, 6 parts of silane, 10 parts of silicon hydride oil, 1 part of DBPMH (2,5-dimethyl-2,5-di (tert-butylperoxy) hexane) and 1.5 parts of boric acid ester and is prepared by copolymerizing, forming and vulcanizing the raw materials in parts by weight per se. The silica gel sealing medium partition plate is formed by copolymerizing dimethyl siloxane and a small amount of vinyl siloxane, wherein the content of vinyl is 0.1%-0.3%, the tensile strength of a finished product reaches 7.2 MPa, the elongation at break reaches 600%, the hardness reaches 61 (A), the breakdown voltage reaches 19 Mv / m, the volume resistance reaches 9.2*1014 omega.cm, the brittleness temperature reaches -65 DEG C, and the using temperature range is -50 DEG C-+250 DEG C.

Owner:江苏亚邦新材股份有限公司

Polymerizable Hybrid Polysiloxanes and Preparation

The present invention relates to a process of making a polymerizable hybrid polysiloxane or a polymerizable hybrid siloxane. The process includes reacting an organopolysiloxane or organosiloxane having an average of at least 3 silicon hydride (SiH) groups per molecule, a polyoxyethylene, and a catalyst. The process also optionally includes adding a stabilizer, a catalytic inhibitor, a solvent, and an unsaturated reactant selected from substituted and unsubstituted unsaturated organic compounds.

Owner:DOW CORNING TAIWAN

Methods to form electronic devices and methods to form a material over a semiconductive substrate

InactiveUS20060166431A1Semiconductor/solid-state device manufacturingCapacitorsSilica hydrideDoped oxide

Owner:THAKUR RANDHIR

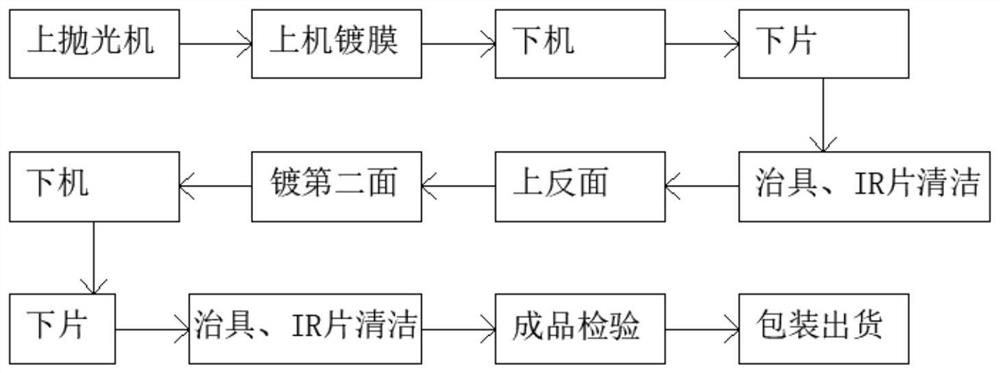

3D structured light 940nm narrow-band optical filter and preparation method thereof

ActiveCN111638572AMeet the requirements of large angle and small offsetReduce offsetOptical elementsSilica hydrideRefractive index

Owner:苏州京浜光电科技股份有限公司

Silicon-modified crumb rubber composition

Owner:MICHELIN RECH & TECH SA

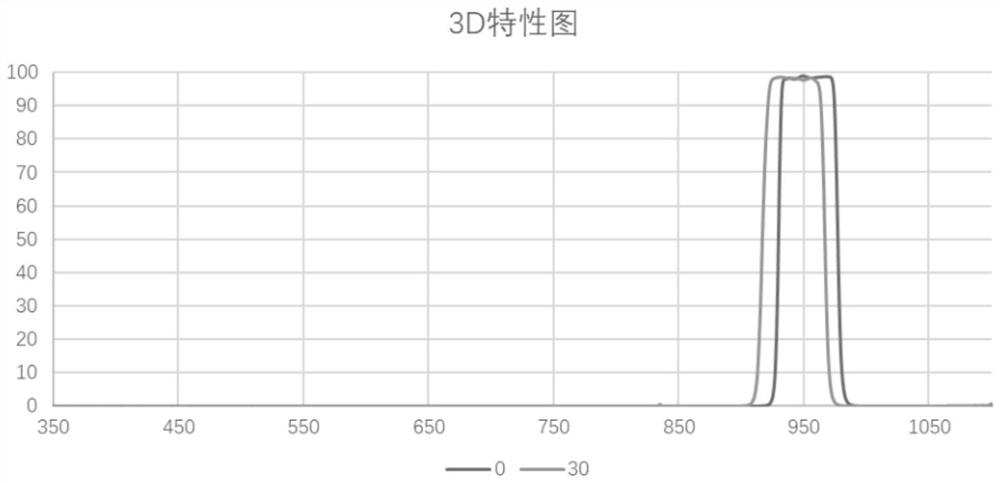

Infrared band-pass filtering structure and infrared band-pass filter using same

PendingCN112462461AReduce internal stressLess identifiableOptical filtersBandpass filteringAngle of incidence

The invention provides an infrared band-pass filtering structure which is formed by alternately stacking a plurality of silicon aluminum hydride layers and a plurality of lower refractive index layers, the lower refractive index layers are oxide, the infrared band-pass filtering structure is provided with a passband which is at least partially overlapped within the wavelength range of 800 nm to 1600 nm, the passband is provided with a central wavelength, and the incident angle of the central wavelength is changed from 0 degree to 30 degrees, the magnitude deviation amplitude of the central wavelength is smaller than 11 nm; the infrared band-pass filter is characterized in that the infrared band-pass filtering structure is formed on a first side surface of a substrate, and an anti-reflection layer is formed on a second side surface, opposite to the first side surface, of the substrate; therefore, the sputtering efficiency can be improved, the manufacturing cost can be greatly reduced, the warping amount of the film layer can be reduced, and the problem that corners are prone to breakage during post-processing cutting is solved.

Owner:KINGRAY TECH CO LTD

Curable resins for LED encapsulation

InactiveUS20130190446A1High transparencyEasy to prepareSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceSilica hydride

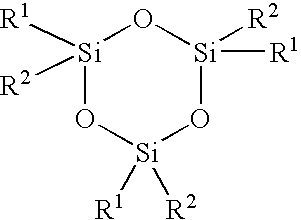

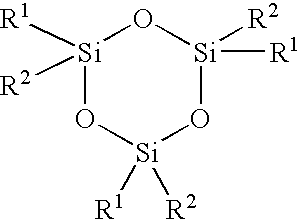

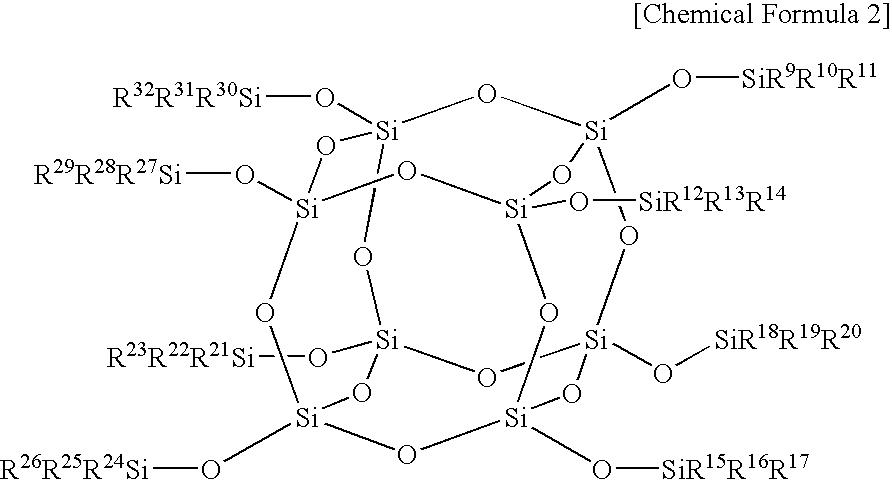

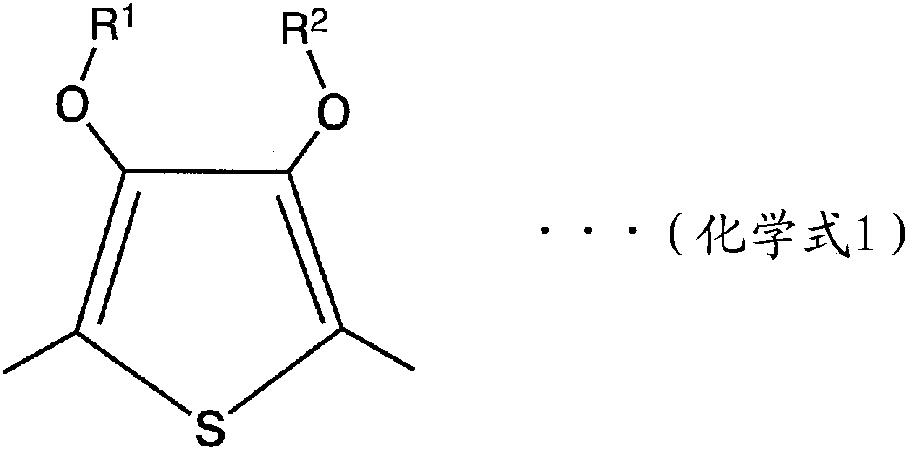

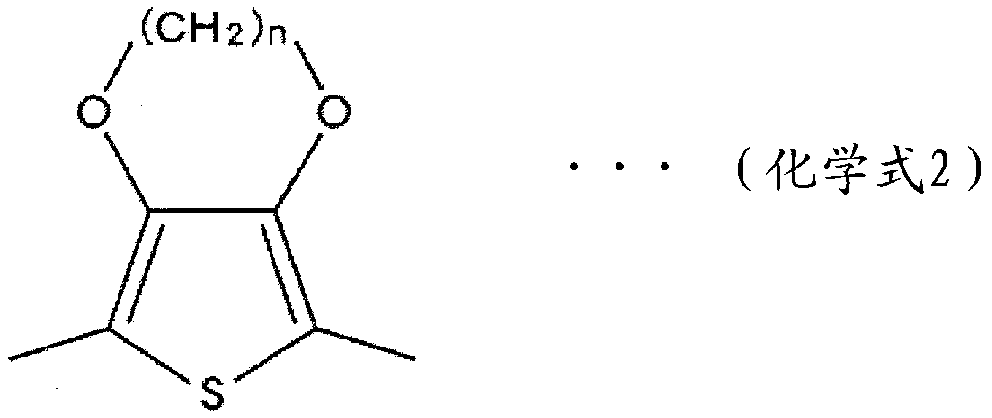

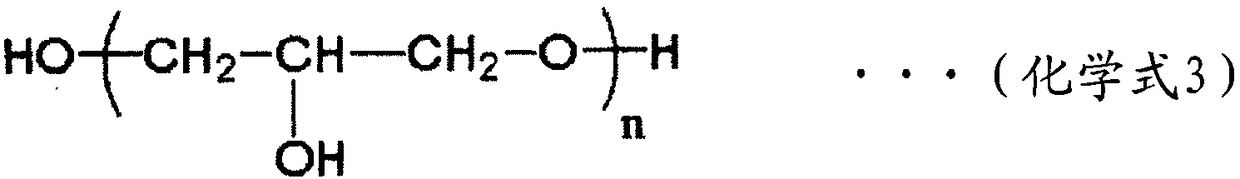

The present invention relates to a curable organopolysiloxane composition, which comprises:(A) an organocyclosiloxane having alkenyl groups, represented by the following formula (I)wherein n=3 or 4;(B) a hydrosilicone resin of formula (II)(R1R2R3SiO1 / 2)m.(R4R5SiO2 / 2)D.(R6SiO3 / 2)T.(SiO4 / 2)Q (II)wherein R1 to R5 are identical or different groups selected from organic groups and hydrogen atom, and at least one of R1 to R5 is a hydrogen atom directly bonded to a silicon atom, and on average at least two hydrogen atoms directly bonded to silicon atoms are contained in one hydrosilicone resin molecule, R6 is an organic group identical to or different from R1 to R5, as organic groups R1 to R6 may independently be linear / branched alkyl or alkenyl groups having 1-20 carbon atoms or halides thereof; cycloalkyl groups or cycloalkenyl groups having 5-25 carbon atoms or halides thereof;M, T and Q each represents a number ranging from 0 to less than 1, 0<D<1, M+D+T+Q=1, and T+Q>0; and(C) platinum-based catalysts.

Owner:HENKEL KGAA

Mold release film

ActiveCN108883615ASuitable for protective purposesFilm/foil adhesivesSynthetic resin layered productsPolyesterPlatinum

Provided is a mold release film which exhibits excellent releasability from an adhesive, while being suppressed in migration, and which is suitable for the purpose of protecting various adhesive layers. A mold release film which has, on at least one surface of a polyester film, a silicone-based mold release layer that is formed from a mold release agent composition containing a first polydimethylsiloxane which has a weight average molecular weight of from 500 to 30,000 (inclusive), while having at least one alkenyl group in each molecule, a second polydimethyl siloxane which has a weight average molecular weight of from 150 to 10,000 (inclusive), while having at least one hydrosilyl group in each molecule, and a platinum-based catalyst.

Owner:MITSUBISHI CHEM CORP

Terrace and construction method thereof

The invention provides a terrace and a construction method thereof, and belongs to the research field of terraces. The invention provides a terrace for overcoming the problem that the exiting terrace material cannot be directly applied to a swimming pool. The terrace is prepared from the following components in parts by weight: 25-30 parts of sawdust, 30-40 parts of plastic, 10-20 parts of polyacrylate, 10-15 parts of butyl acetate, 3-5 parts of corundum powder, 3-5 parts of butadiene rubber, 5-10 parts of hydrogenated silicon oil, 1-3 parts of plasticizer, 0.2-0.3 part of preservative, 3-5 parts of diethylene triamine and 2-4 parts of toner. The terrace provided by the invention is used for reducing possible risks of hard bottom and side walls of the swimming pool on users, reinforcing the adaptability of the inner walls of the swimming pool on impact caused by water, non-water and different water temperatures and enhancing the adaptability of the swimming pool, so that the terrace is conducive to popularization and application.

Owner:哈尔滨中建璟园科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com