Infrared band-pass filtering structure and infrared band-pass filter using same

A band-pass filter and filter structure technology, applied in the field of infrared band-pass filter structure, can solve the problems of high production cost, low sputtering efficiency, and easy chipping of the film layer, so as to reduce resource costs, improve yield, and improve competition advantage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

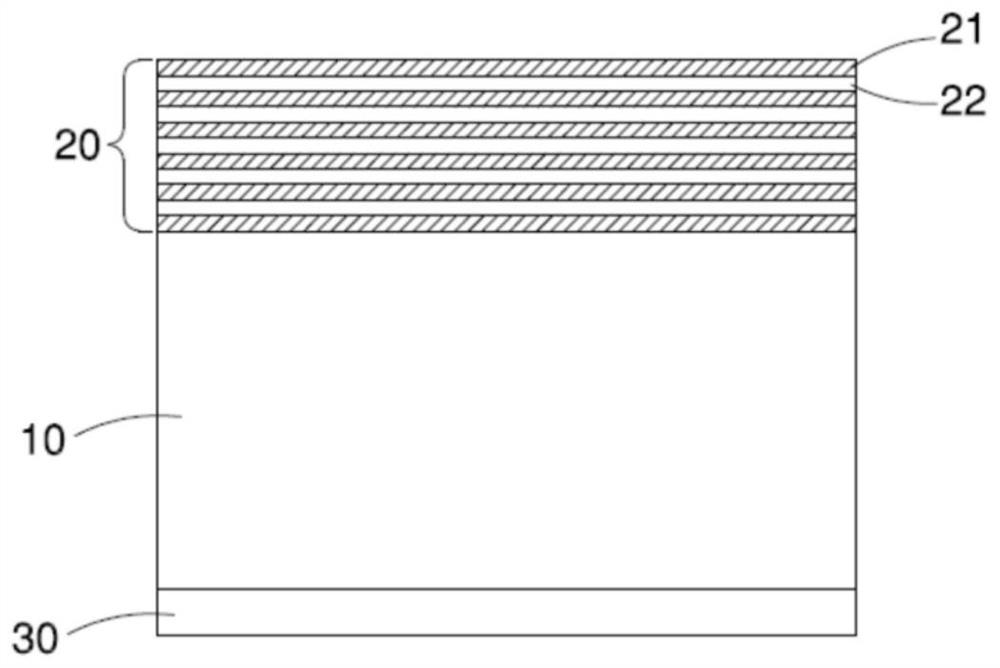

[0026] see figure 1 As shown, it is shown that the infrared bandpass filter of the present invention includes a substrate 10, an infrared bandpass filter structure 20 and an anti-reflection (AR) layer 30, wherein:

[0027] The substrate 10 is glass, and has a first side and a second side opposite to the first side.

[0028] The infrared bandpass filter structure 20 is formed on the first side of the substrate 10, and is formed by stacking multiple silicon aluminum hydride (SiAl:H) layers 21 and multiple lower refractive index layers 22 alternately, so that the infrared bandpass filter structure 20 Having a passband at least partially overlapping in the wavelength range from 800nm to 1600nm, the passband having a central wavelength that varies in magnitude when the angle of incidence changes from 0° to 30° The magnitude of shifts is less than 11nm (about 10.3-10.5nm). Moreover, the infrared bandpass filter structure 20 has a thickness of 3000-5500nm, has a high OD value in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com