Assembly tool special for ship subsection and slipway closure bulb code-free

A technology for assembling tooling and ball joints, which is applied to ships and other directions, to improve the working environment, save consumables and labor, and facilitate installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

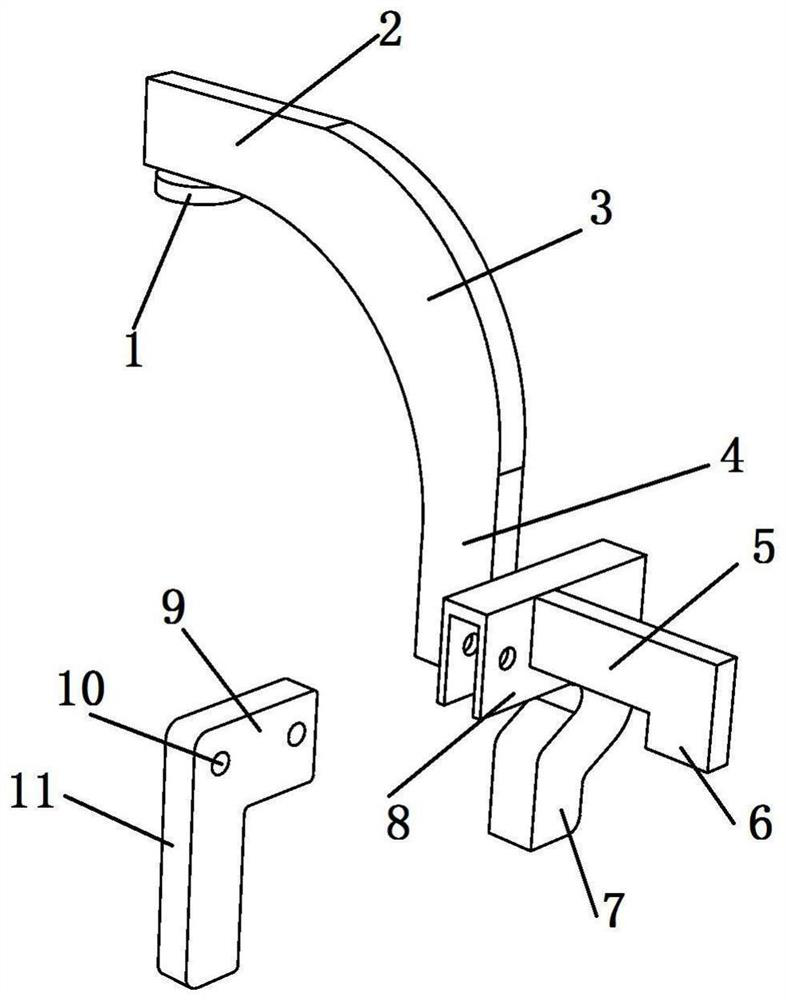

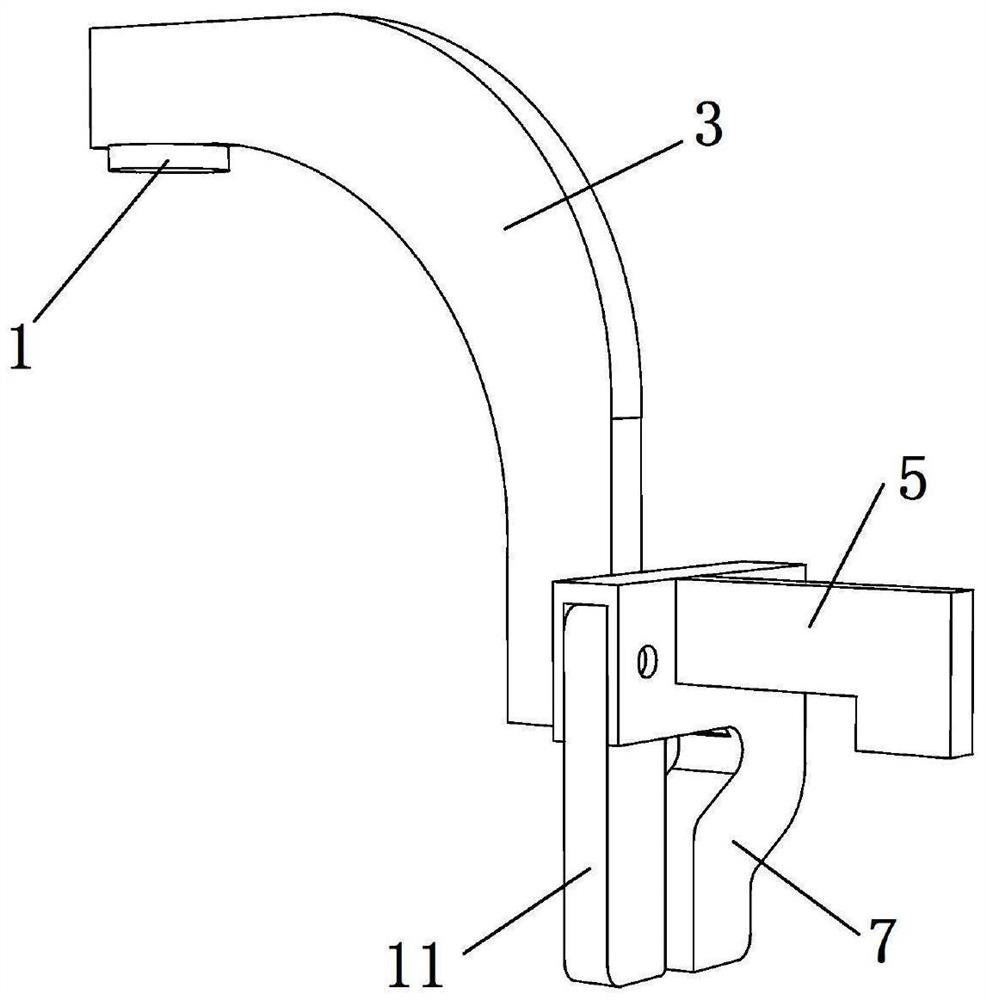

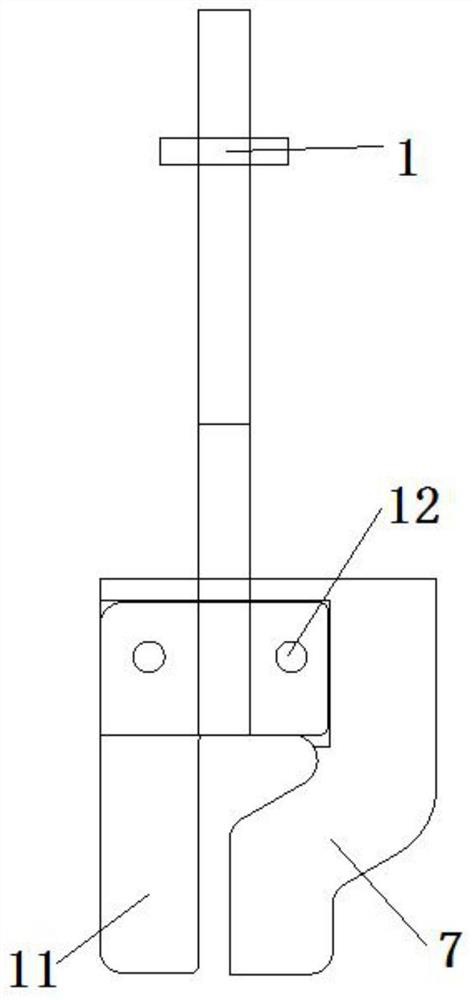

[0015] Such as Figure 1-4 As shown, this embodiment provides a special assembly tool for ship segmentation and ship berth closing ball head without code, including a tightening plate, a fixed groove seat, a longitudinal support plate, and a ball head fixing base, and the tightening plate includes a horizontal plate and a vertical plate , the bottom of the horizontal plate is provided with a fixed groove seat connected with the top of the jack, the outer side of the vertical plate is connected with one side of the ball head fixed base, and the other side of the ball head fixed base is connected with a longitudinal support plate.

[0016] Since the low-spherical flat steel with smaller height and dimension may be located on the left or right, there are two groups of special assembly tools mentioned above, which are arranged symmetrically and selected according to actual needs; the ball head fixing base is installed on the low-spherical flat steel head , the jack sits on top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com