Slender casting mould assembling positioning pin

A positioning pin, thin and high type technology, applied in the field of mechanical casting, can solve the problems of sand rubbing between the cavity and the sand core, unsteady box closing, small cavity space, etc., to achieve reliable and convenient positioning, improve stability, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

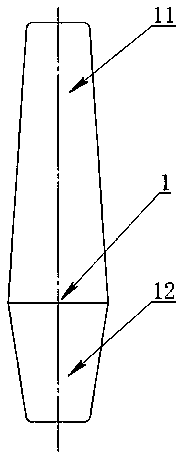

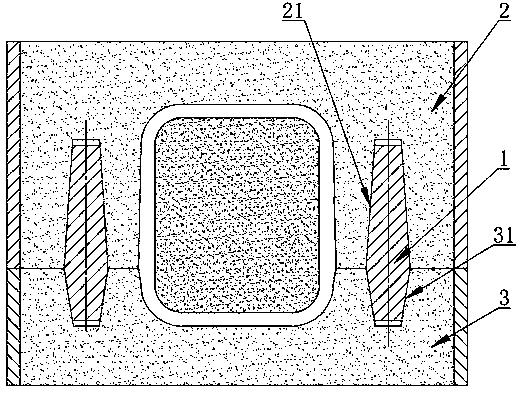

[0016] Such as figure 1 , figure 2 As shown, a kind of slender high-type casting combined box locating pin, comprises locating pin 1 main body, and locating pin 1 main body is the overall structure of the asymmetric conical frustum with big middle, two ends are small, and locating pin 1 body can be divided into upper part 11 and lower part 12 , the upper part 11 is a truncated conical body with a small taper, the lower part 12 is a truncated conical body with a larger taper, and the boundary between the upper part 11 and the lower part 12 is the bottom surface of the truncated conical body and the upper box sand mold 2 and the lower box sand mold 3 combined box parting surface, when the upper box sand mold 2 and the lower box sand mold 3 are combined, the lower part 12 of the positioning pin 1 is placed in the lower po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com