A kind of opening structure, fire extinguishing device, fireproof window and production process of fireproof window

A technology of fire extinguishing device and window frame, which is applied in the production process of fire extinguishing device, fireproof window and fireproof window, and the field of opening structure, can solve the problems of lack of continuity of fire extinguishing and poor effect of fire extinguishing, and achieve good fire protection effect and improve fire extinguishing effect. Effect, the effect of easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

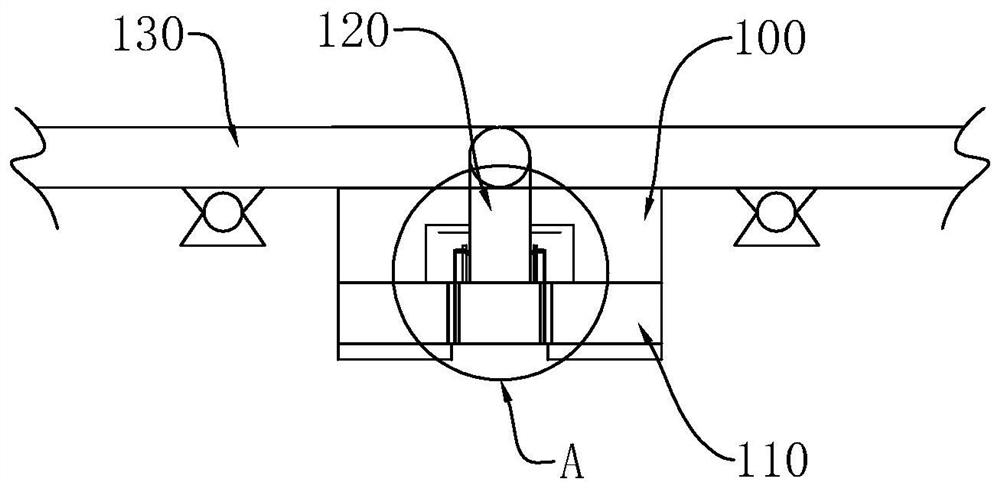

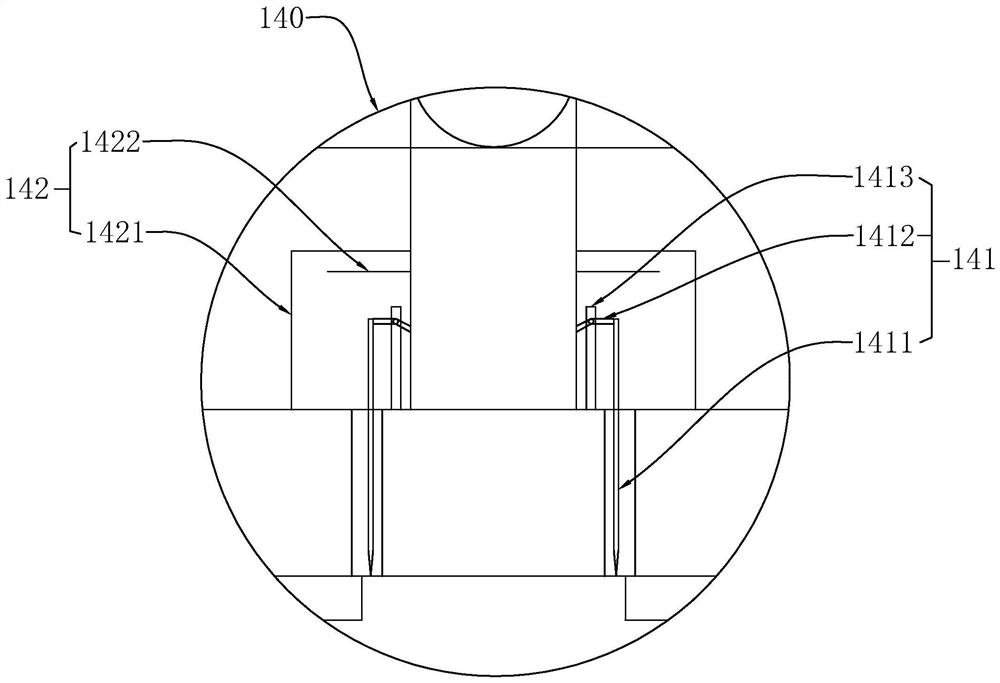

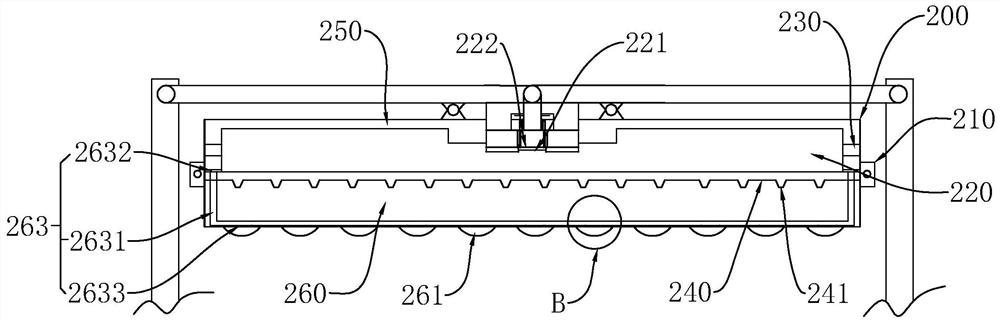

[0055] refer to figure 1 , an opening structure shown in this embodiment includes a drive chamber 100, a piston 110 provided in the drive chamber 100, a drive rod 120 that drives the piston 110 to move upward, and a plurality of hinge rods 130 that are hinged to the upper end of the drive rod 120, The piston 110 is connected to the lower end of the driving rod 120, the upper part of the piston 110 is provided with a stepped transmission assembly 140, and the bottom of the driving chamber 100 corresponds to the air outlet 221 of the air storage chamber 220 of the fire extinguishing device. The initial state of the piston 110 is crimped at the air outlet 221. In the case of external drive, the hinged rod 130 lifts the driving rod 120. During the lifting process of the driving rod 120, the diaphragm 222 of the air outlet 221 is first pierced and opened. The gas outlet 221 continues to lift the driving rod 120 to drive the piston 110 away from the gas storage port to realize the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com