A hammer capable of active beating based on electromagnetic drive

An electromagnetically driven and active technology, applied in the direction of striking tools, manufacturing tools, lightweight impact tools, etc., can solve the problems of inability to complete the striking work, poor nail striking direction, etc., to improve the ability to adapt to multi-space environment and improve the impact force. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

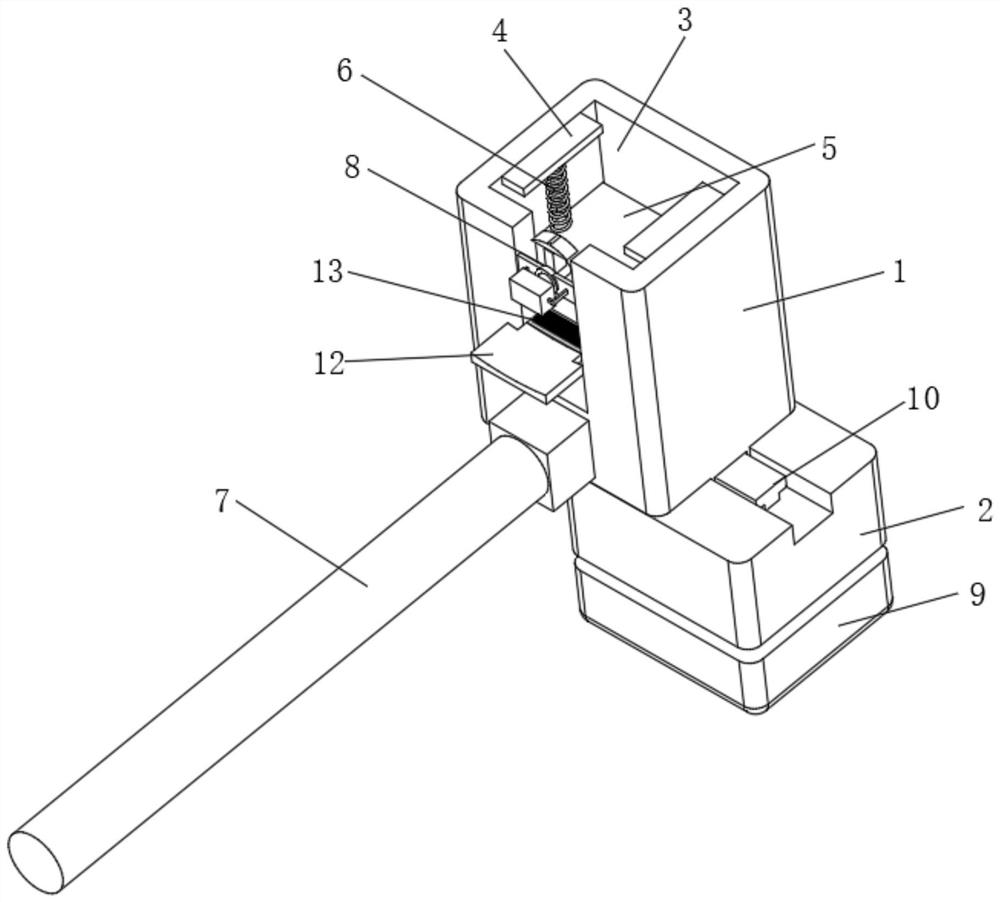

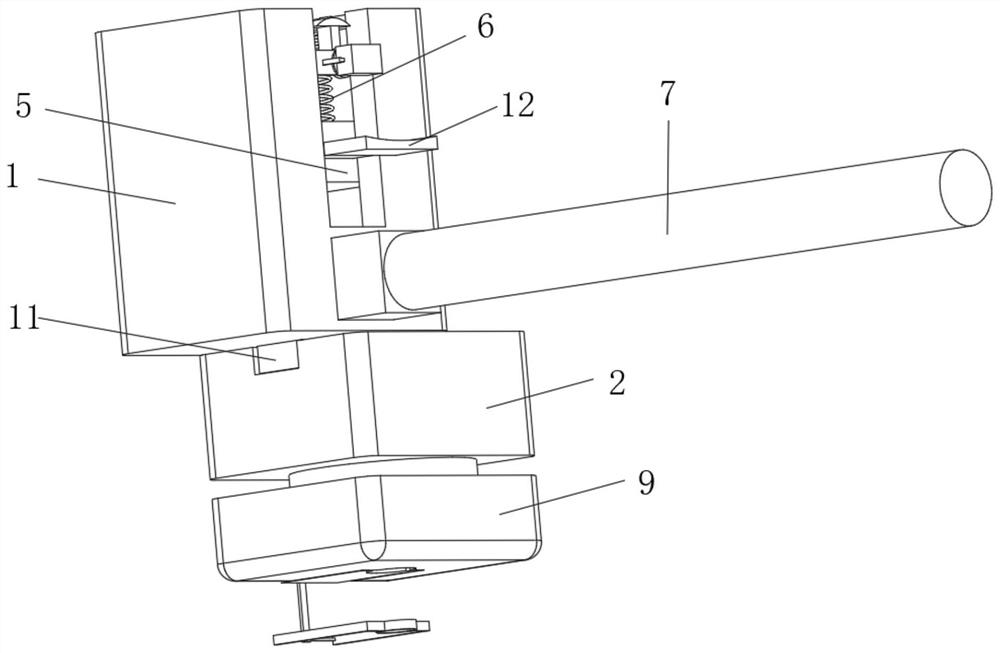

[0036] Such as Figure 1-3 As shown, the present invention provides a technical solution: a hammer that can realize active beating based on electromagnetic drive, including a main driving hammer head 1 and an adjusting auxiliary hammer head 2, and the top of the main driving hammer head 1 is provided with an impact limiting groove 3. Both sides of the top top of the impact limiting groove 3 are fixedly connected with a limiting baffle 4, and the vertical position inside the impact limiting groove 3 is slidingly connected with an impact auxiliary block 5, and both sides of the top of the impact auxiliary block 5 pass through a return spring 6 It is fixedly connected with the limiting baffle 4, the middle position on the back of the main driving hammer 1 and the position corresponding to the impact limiting groove 3 is provided with an opening, the back of the main driving hammer 1 is fixedly connected with a handle 7 at a position close to the bottom, the main driving hammer 1 ...

Embodiment 2

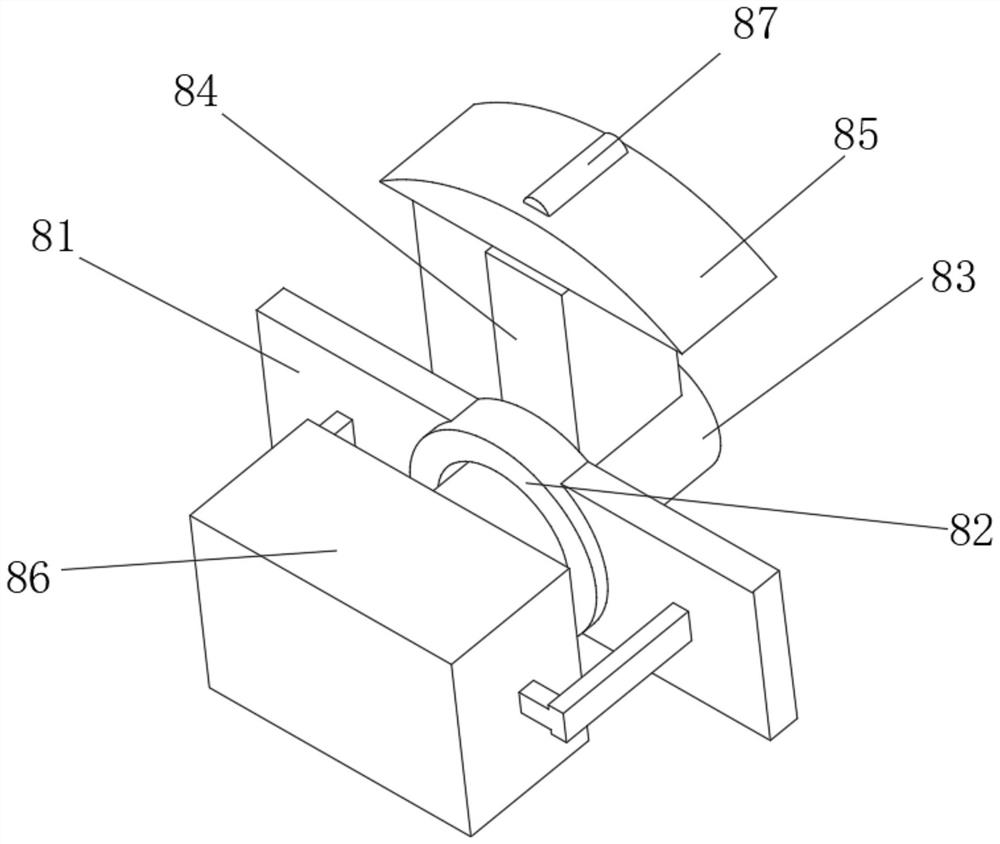

[0040] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a hammer that can realize active beating based on electromagnetic drive. The electromagnetic beating mechanism 8 includes a supporting carrier 81, which is connected with the main driving hammer 1. Open internal fixed connection, the middle position of the support carrier plate 81 is fixedly connected with a limiting bearing 82, the inside of the limiting bearing 82 penetrates and is connected with a limiting rotating shaft 83, and the limiting rotating shaft 83 is fixed close to the top of the main driving hammer head 1 inner measuring A transmission strut 84 is connected, and an electromagnet 85 is fixedly connected to one end of the transmission strut 84 away from the limiting rotating shaft 83 . The active striking force of the hammer is improved through the magnetic repulsion, so that the hammer can complete the striking without swinging.

Embodiment 3

[0042] Such as Figure 4 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a hammer that can realize active beating based on electromagnetic drive, and a micro motor 86 is fixedly connected to the outer surface of the support carrier The output shaft of the motor 86 is fixedly connected with the limiting rotating shaft 83 . The mechanical cycle rotation realizes the active striking ability of the hammer and improves the impact force of the hammer without swinging.

[0043] The intermediate position of electromagnet 85 outsides is rotatably connected with limiting roller 87, and the outer surface of electromagnet 85 is correspondingly arranged with magnet block 13. The electromagnet 85 adopts an outwardly protruding arc, avoiding the damage caused when the electromagnet 85 touches with the magnet block 13, and improving the safety of the structural work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com