Environment-friendly composite adhesive and processing equipment thereof

A technology for processing equipment and compound glue, applied in the field of compound glue, can solve the problems of not green environmental protection, difficult to clean, and the colloid is not pure enough, so as to achieve the effect of increasing the mixing area and reducing the damage caused by knocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

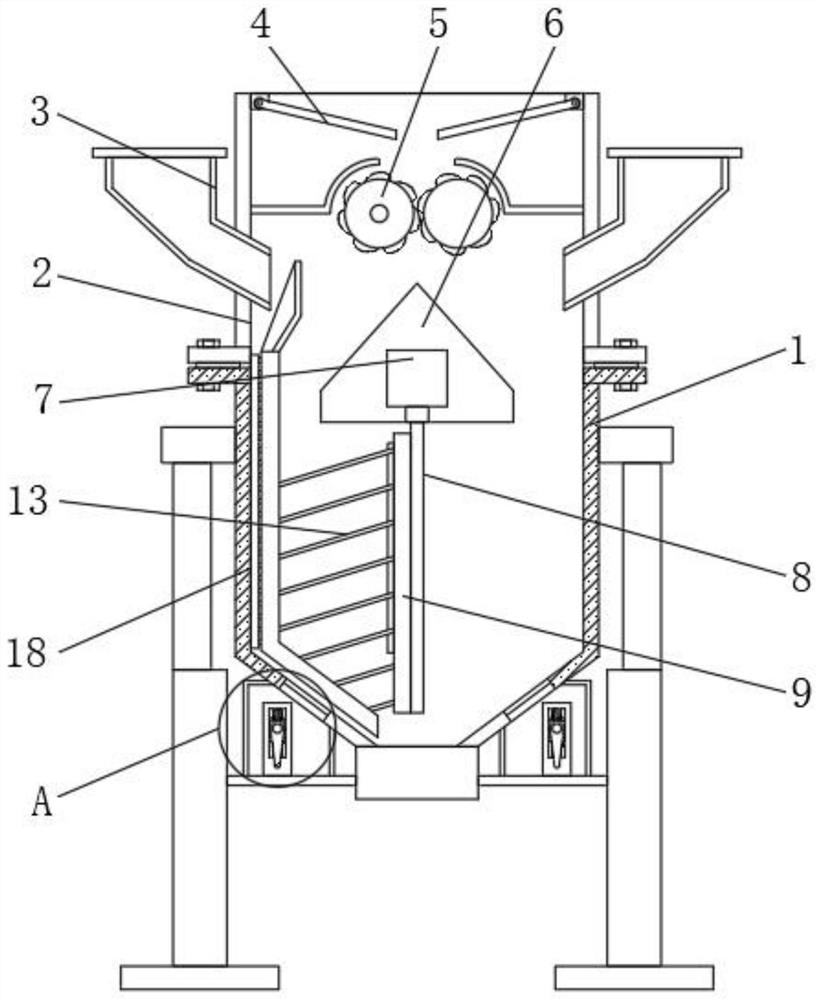

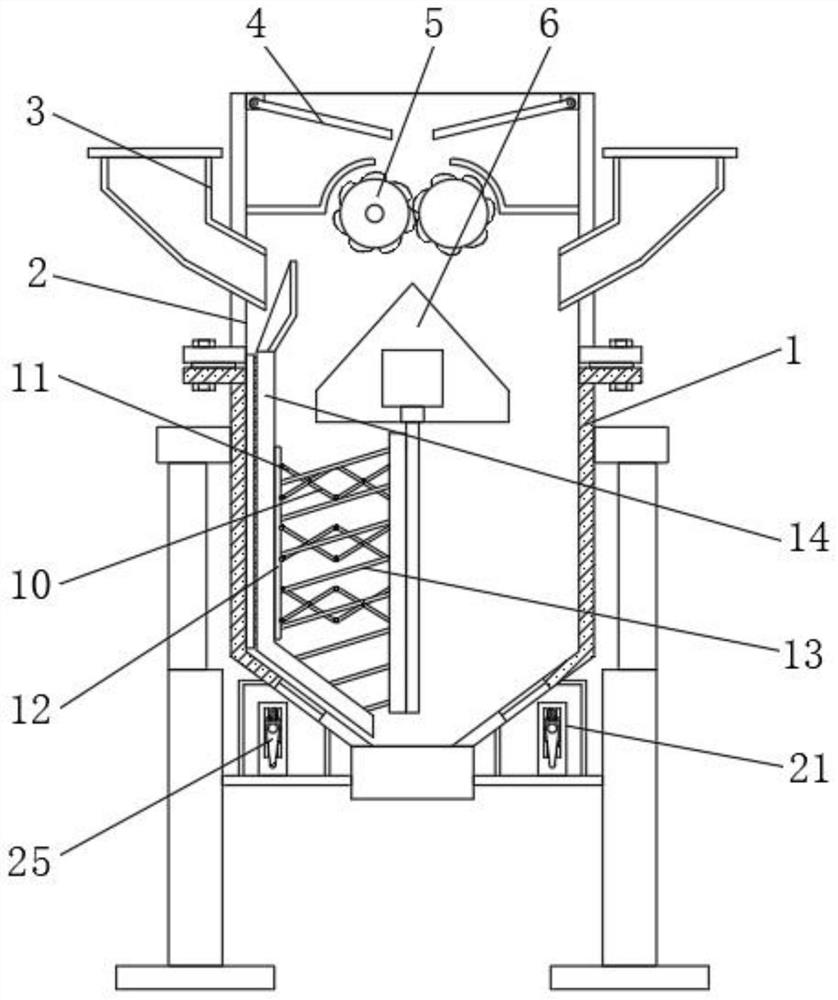

[0037] see Figure 1-4 , an environment-friendly composite glue and its processing equipment, the mass percentage of ingredients of the composite glue includes: 60% of cornstalks, 25% of white Portland cement, 10% of viscous agent, and 5% of trace elements.

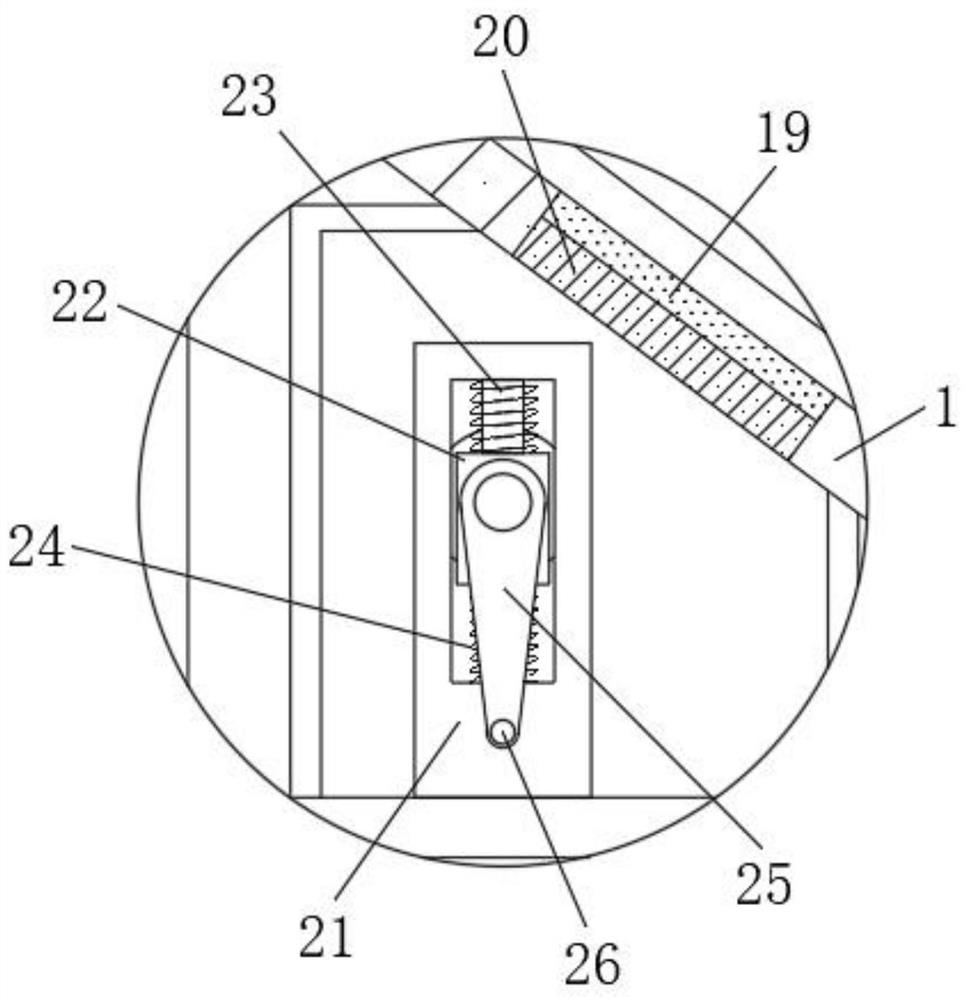

[0038] The processing equipment includes a mixing box 1, a feeding box 2 is fixedly installed at the top of the mixing box 1, a feeding port 3 is fixedly installed on the left and right sides of the feeding box 2, and a vibration panel 4 is connected to the inner side of the top of the feeding box 2. , the lower side of the vibration panel 4 is provided with a pulverizing shaft 5, the lower side of the pulverizing shaft 5 is fixedly installed with a buffer cone 6, the inside of the buffer cone 6 is fixedly installed with a drive motor 7, and the bottom output end of the drive motor 7 is connected with a mixing shaft 8 , the left end of the mixing shaft 8 is fixedly installed with a restraint shaft 9, the left side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com