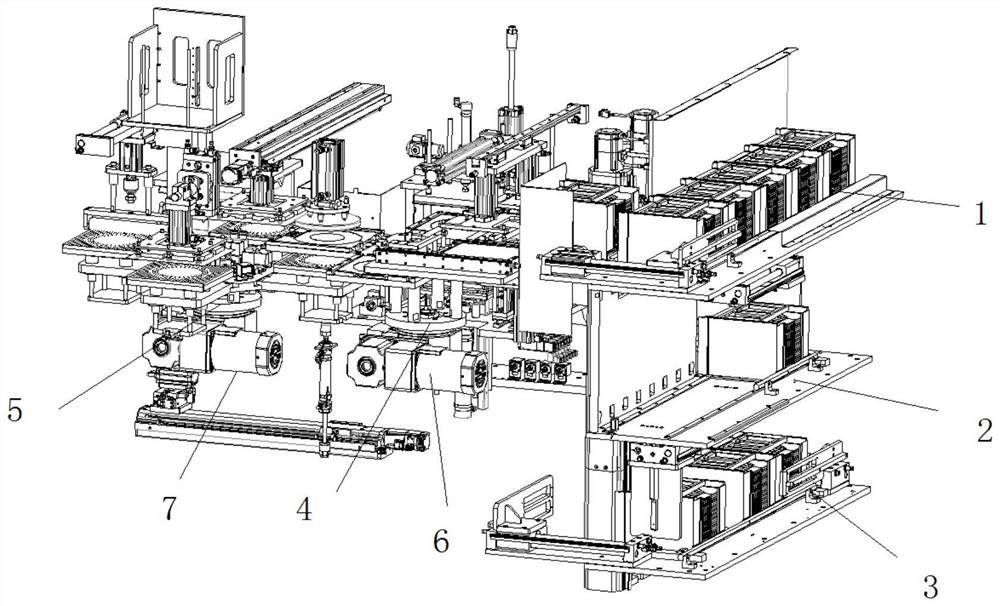

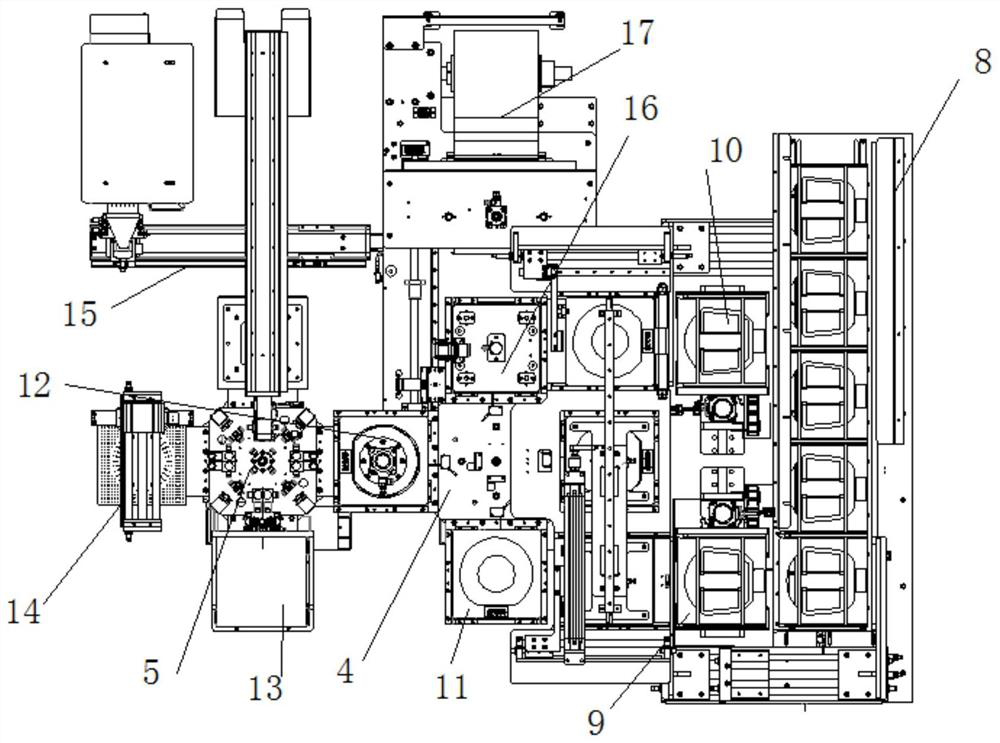

Double-rotary-disc type film discharging and pasting machine

A technology of double turntables and turntables, used in rotary conveyors, conveyors, electrical components, etc., can solve the problems of complex mechanism and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0018] refer to Figure 1-2 , a double turntable type film laminating machine, comprising an iron frame transfer turntable 4, a film transfer turntable 5, a clamping device 8, an iron frame clamping operation device 9 for the film to be lowered, and an iron frame clamp loading device after the film is pasted 10. Counting device 11, film lowering device 12, release paper sticking device 13, roller rolling device 14, discharge labeling device 15, iron frame film sticking device 16, blue film or white film feeding device 17, clamping device 8 includes the iron frame clamp feeding device 1, the iron frame clamp discharge device 2, the empty clamp transfer device 3, the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap