Hydraulic platform vehicle for installing instrument in limited space and installation method

A hydraulic platform technology in a confined space, applied in the direction of hoisting devices, lifting frames, etc., can solve the problems of high installation precision, inability to use cranes for installation, and large man-hour consumption, so as to ensure safety, reduce manpower input, and ensure The effect on success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

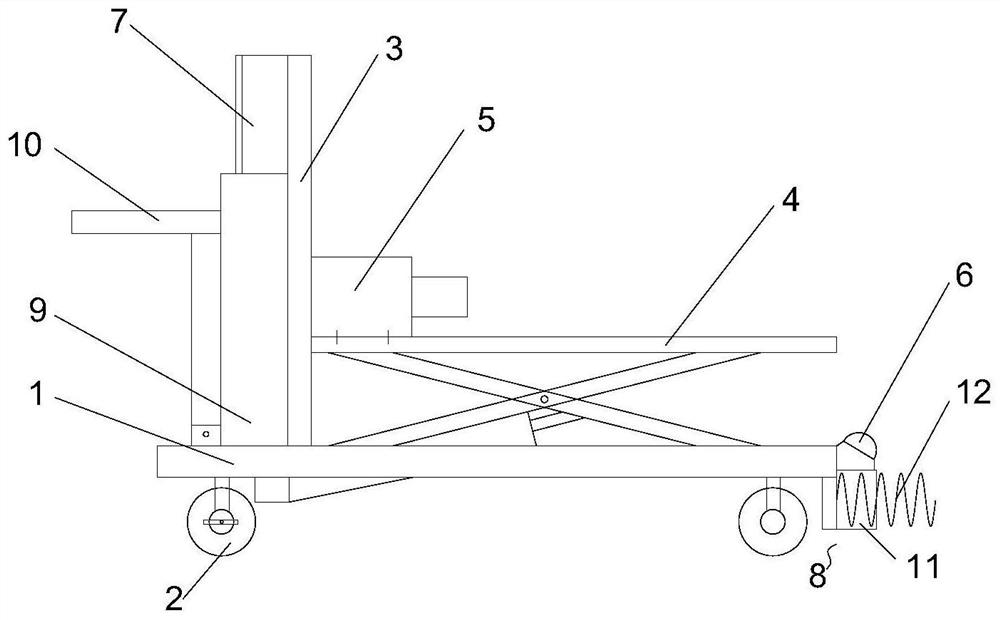

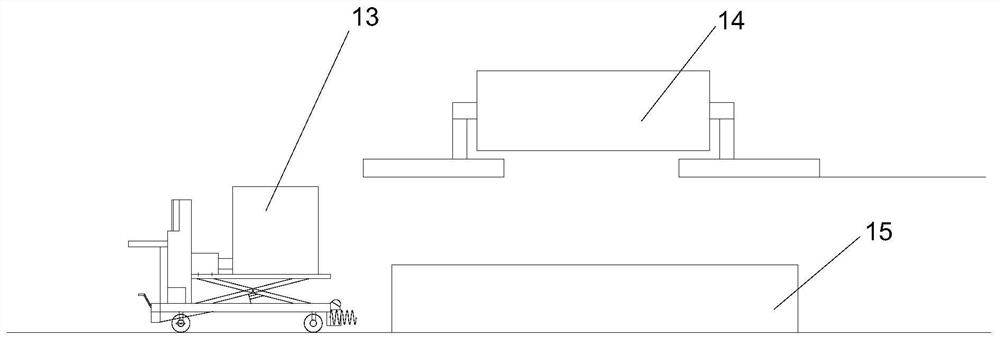

[0015] like figure 1 , a hydraulic platform vehicle for installing instruments in a confined space, comprising a vehicle floor 1, wheels 2, columns 3, a hydraulic lifting platform 4, a propulsion hydraulic cylinder 5, a camera 6, a monitor 7, an anti-collision device 8, and a vehicle floor 1 The bottom of the car floor is provided with wheels 2, and the upper surface of the vehicle floor 1 is provided with a column 3, and one side of the column 3 is provided with a hydraulic lifting platform 4 on the vehicle floor 1. The front end is fixedly connected with the anti-collision device 8, and the anti-collision device 8 includes an outer cylinder 11, and the outer cylinder 11 and the vehicle floor 1 are welded and fixed. A spring 12 is fixedly connected in the outer cylinder 11, and the length of the spring 12 is greater than that of the outer cylinder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com