Follow-flying-type differential lock structure

A differential lock and flywheel technology, applied in the differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem that the turning action of the differential lock is difficult to achieve on the opposite side of the in-situ tank turning action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

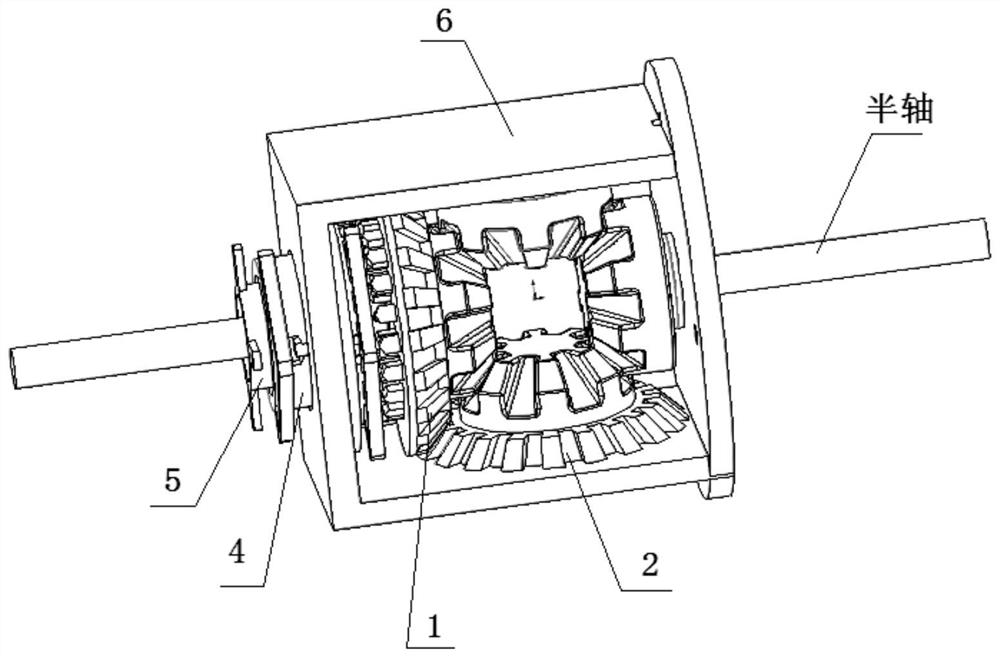

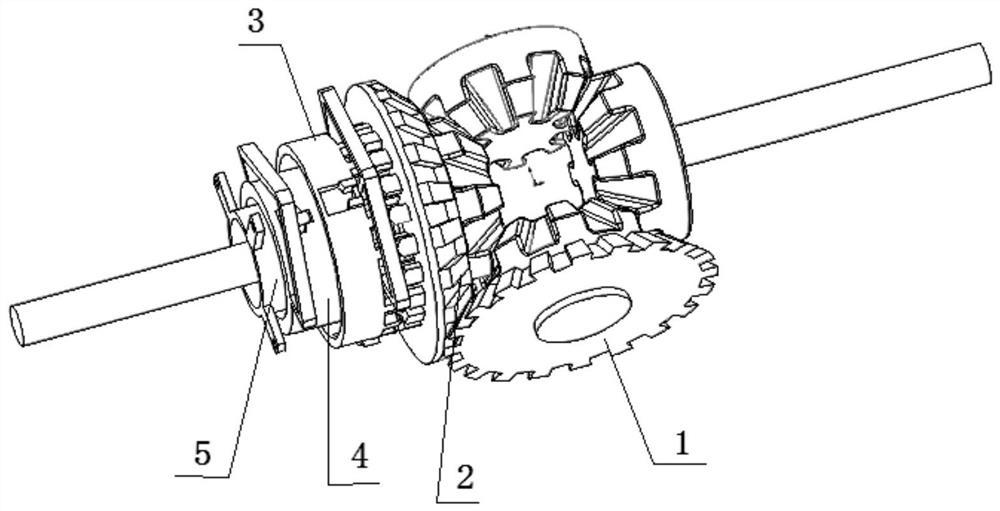

[0038] Such as figure 1 and 2 As shown, a fly-on differential lock structure includes a flywheel 1, a central driven planetary gear 2, a housing fault-tolerant sliding sleeve 3, a housing fault-tolerant sliding sleeve 4, a housing 5 and a housing 6;

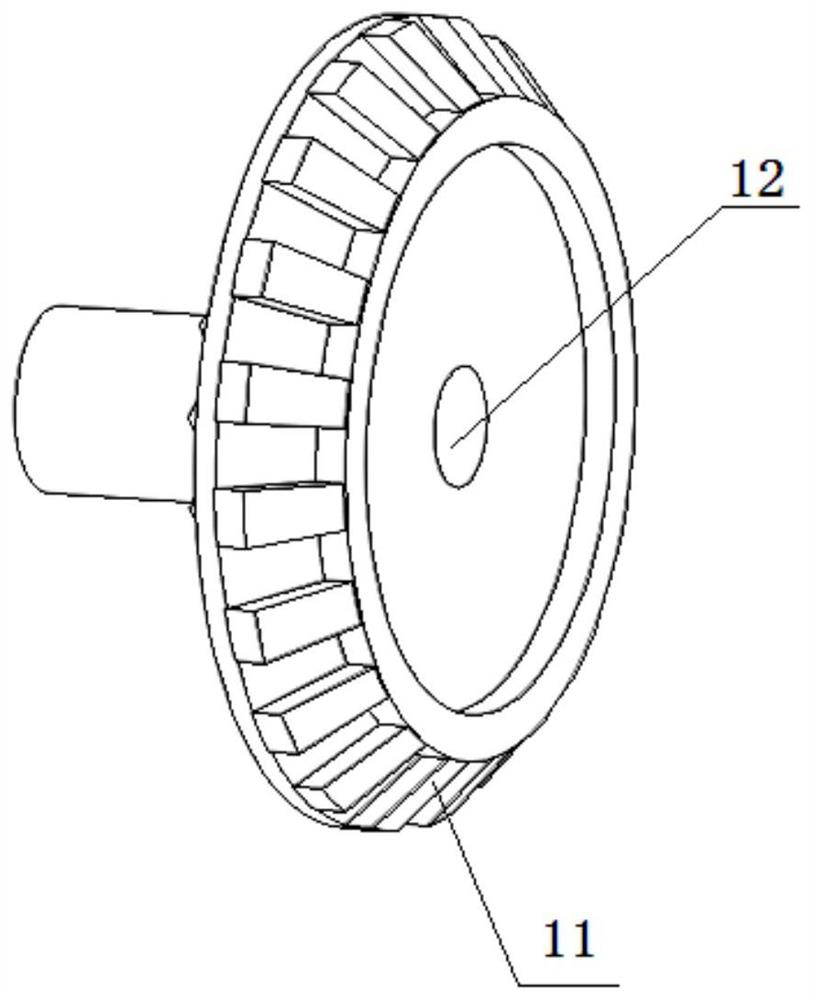

[0039] Such as image 3 and 4 As shown, the front edge of the flywheel 1 is provided with a flywheel bevel tooth 11, the middle is provided with a light through hole 12, the outer ring of the back side of the flywheel 1 is provided with an outer wheel back tooth 13, and the inner ring is provided with an inner wheel back tooth 14;

[0040] Such as Figure 5 As shown, the housing fault-tolerant sliding sleeve 3 is socketed with the casing fault-tolerant sliding sleeve 4, and is toothed with the outer wheel of the flywheel 1. The casing fault-tolerant sliding sleeve 4 is socketed on the casing 5, and the casing The fault-tolerant sliding sleeve 3 is sleeved on the housing 6 .

[0041] Such as Figure 6 As shown, the central d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com