Flow guiding assembly and oil fume treatment device

A technology of oil fume treatment and deflectors, which is applied in the field of range hoods, can solve the problems of consumers such as cleaning troubles and runny noses, and achieve the effect of improving oil pollution and reducing cleaning frequency and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

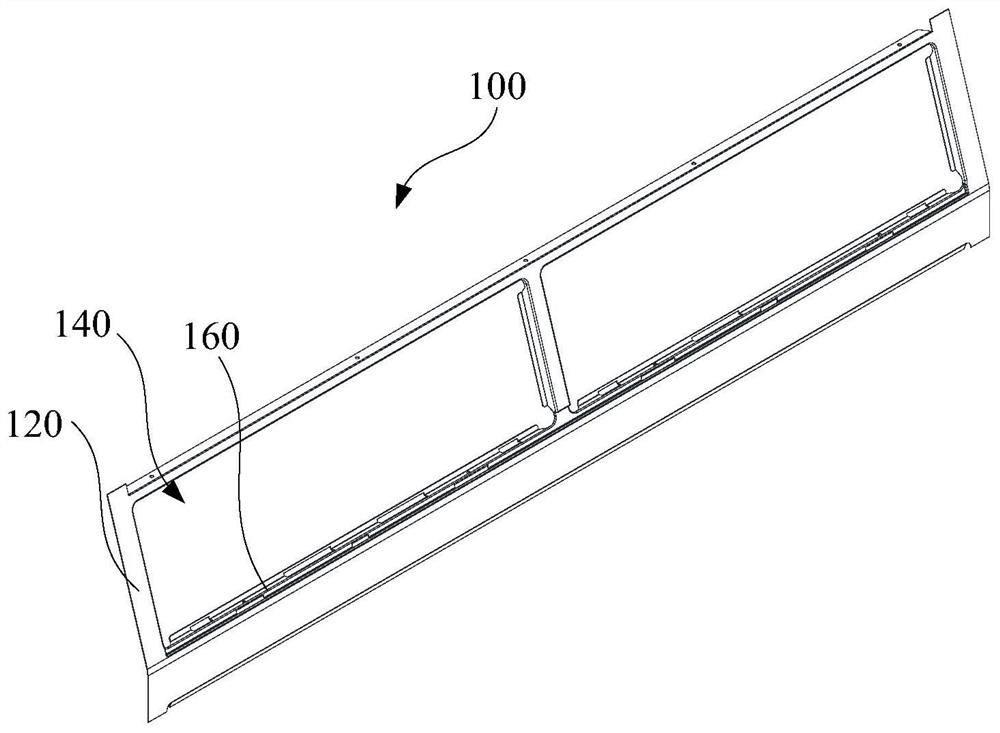

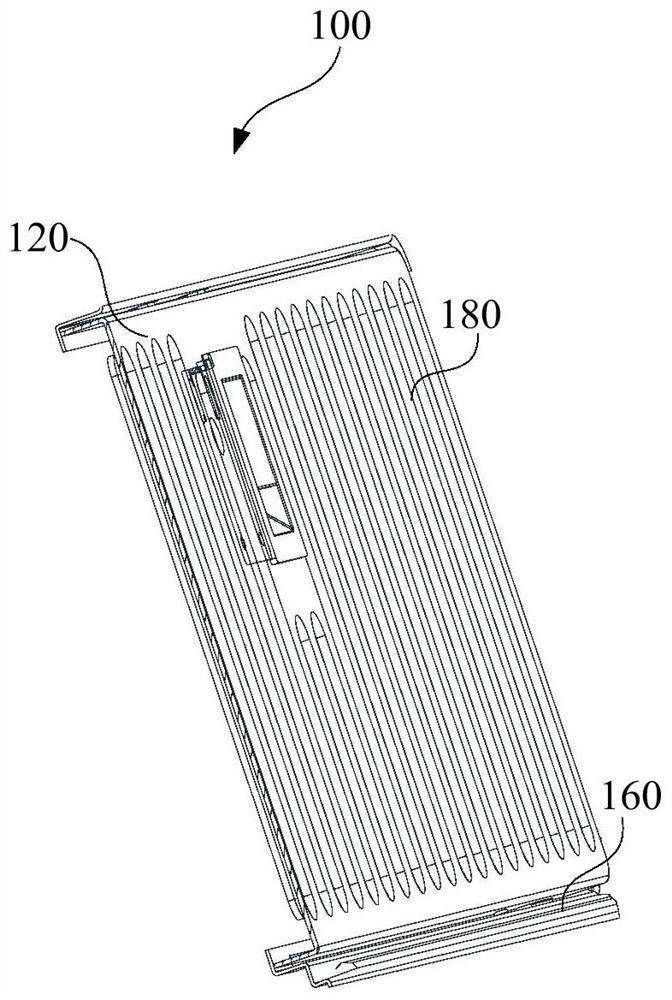

[0065] Such as figure 1 with figure 2 As shown, an embodiment of the present invention provides a deflector assembly 100 for an oil fume treatment device 200 , including: a frame body 120 , a grille 180 and a first deflector 160 , and the air inlet 140 is located in the frame body 120 Above, the grille 180 is connected to the frame body 120, and the grille 180 covers the air inlet 140; The first deflector 160 is located between the bottom surface of the grid 180 and the frame body 120, the first deflector 160 is located below the grid 180, and the first deflector 160 can control the flow of water flowing down from the grid 180. Liquid diversion.

[0066] In this embodiment, the air guide assembly 100 includes a frame body 120 , a grille 180 and a first air guide member 160 , the frame body 120 is provided with an air inlet 140 , and the grille 180 is embedded in the air inlet 140 of the frame body 120 , the grille 180 can guide the air flowing through the air inlet 140, th...

Embodiment 2

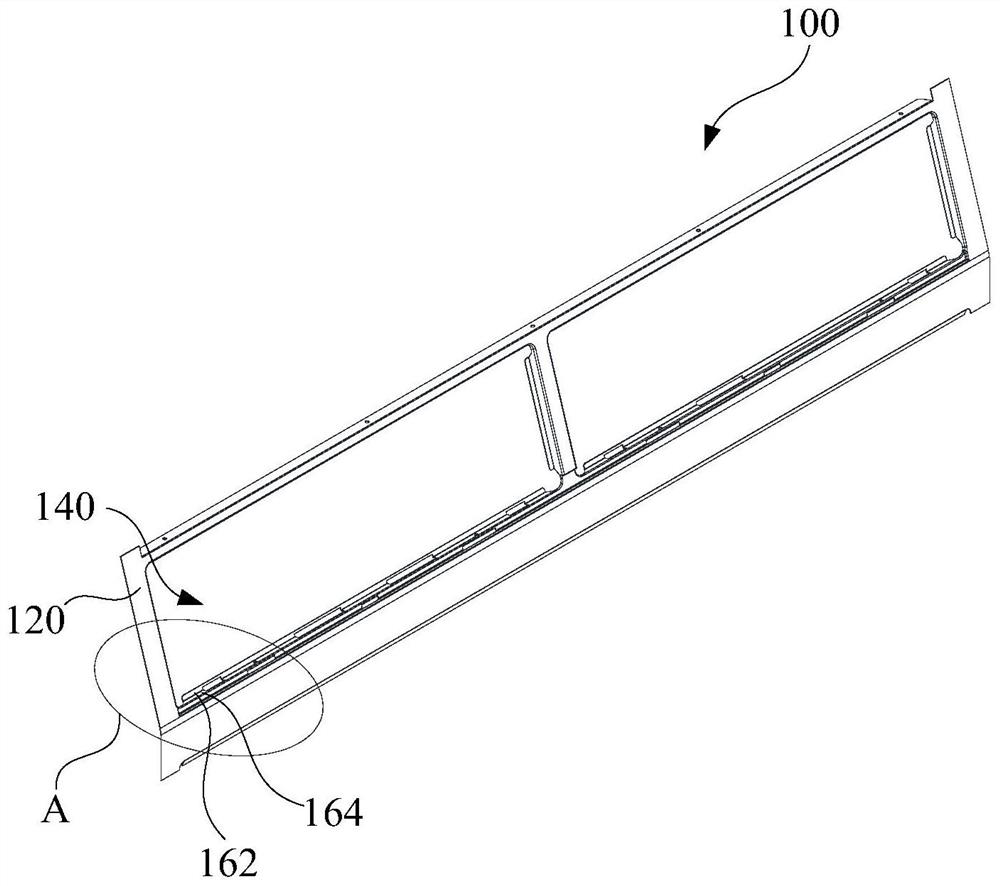

[0085] Such as figure 1 As shown, an embodiment of the present invention provides a deflector assembly 100 for an oil fume treatment device 200 , including: a frame body 120 , a grille 180 and a first deflector 160 , and the air inlet 140 is located in the frame body 120 Above, the grille 180 is connected to the frame body 120, and the grille 180 covers the air inlet 140; The first deflector 160 is located between the bottom surface of the grid 180 and the frame body 120, the first deflector 160 is located below the grid 180, and the first deflector 160 can control the flow of water flowing down from the grid 180. Liquid diversion.

[0086] The first deflector 160 also includes: a connected first plate 162 and a second plate 164, a positioning protrusion 166, an angle is provided between the first plate 162 and the second plate 164, and the angle Greater than or equal to 90° and less than or equal to 180°, the first plate 162 is connected to the frame body 120 , and the firs...

Embodiment 3

[0100] Such as image 3 As shown, an embodiment of the present invention provides a cooking fume treatment device 200, including: a body 210; a smoke guide channel 220, the smoke guide channel 220 is set in the body 210; a smoke baffle 230, the smoke baffle 230 is set in On the body 210; as the flow guide assembly 100 in the first and / or second embodiment above, the flow guide assembly 100 is connected to the smoke baffle 230, and the flow guide assembly 100 is configured to guide the fluid to the smoke guide channel 220 Inside, wherein, the top surface of the smoke baffle 230 is higher than the first deflector 160 in the deflector assembly 100 along the direction of gravity. Therefore, it has all the beneficial effects of the above-mentioned embodiment 1 and embodiment 2, which will not be repeated here.

[0101] In this embodiment, the oil fume treatment device 200 includes a body 210 , a smoke guide channel 220 , a smoke baffle 230 and a flow guide assembly 100 . The smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com