Spray cleaning device for production of quartz ceramic products

A technology of quartz ceramics and cleaning devices, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, filtration and separation, etc., which can solve the problems of inability to collect water resources and inability to fix ceramic products, so as to avoid falling and fragmentation, improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

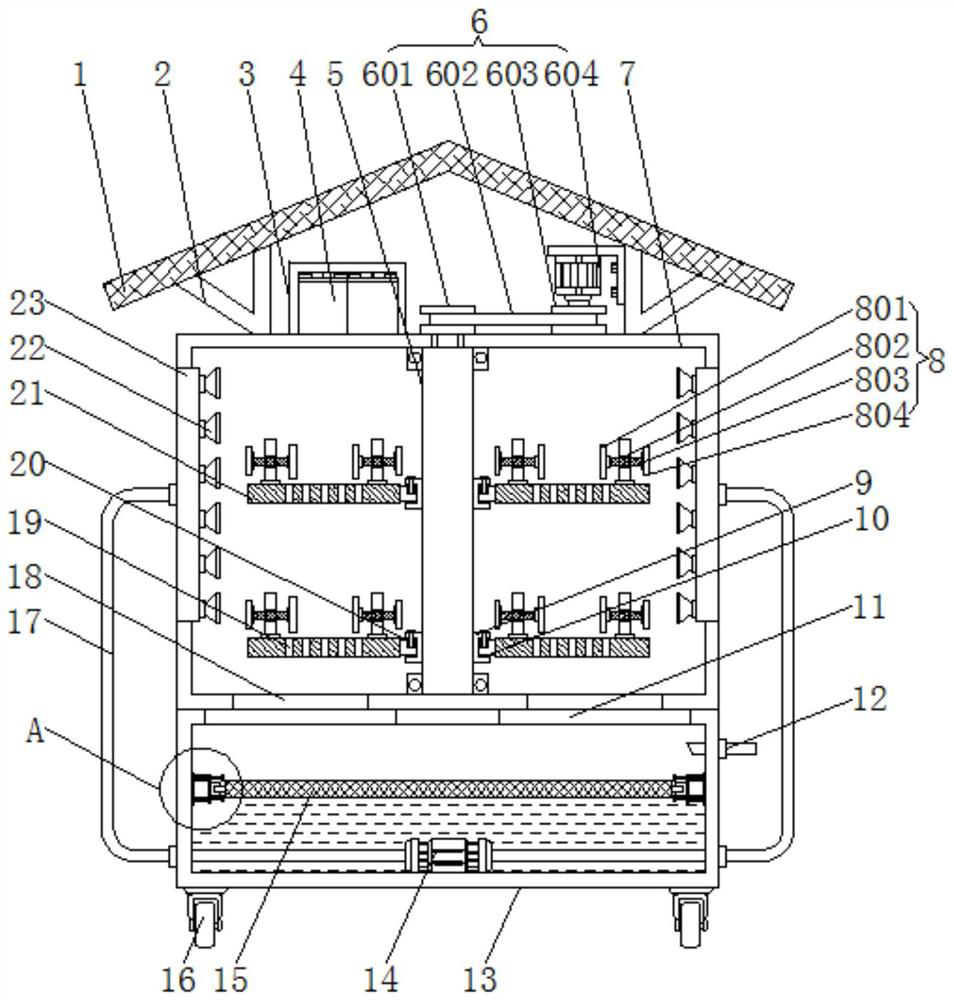

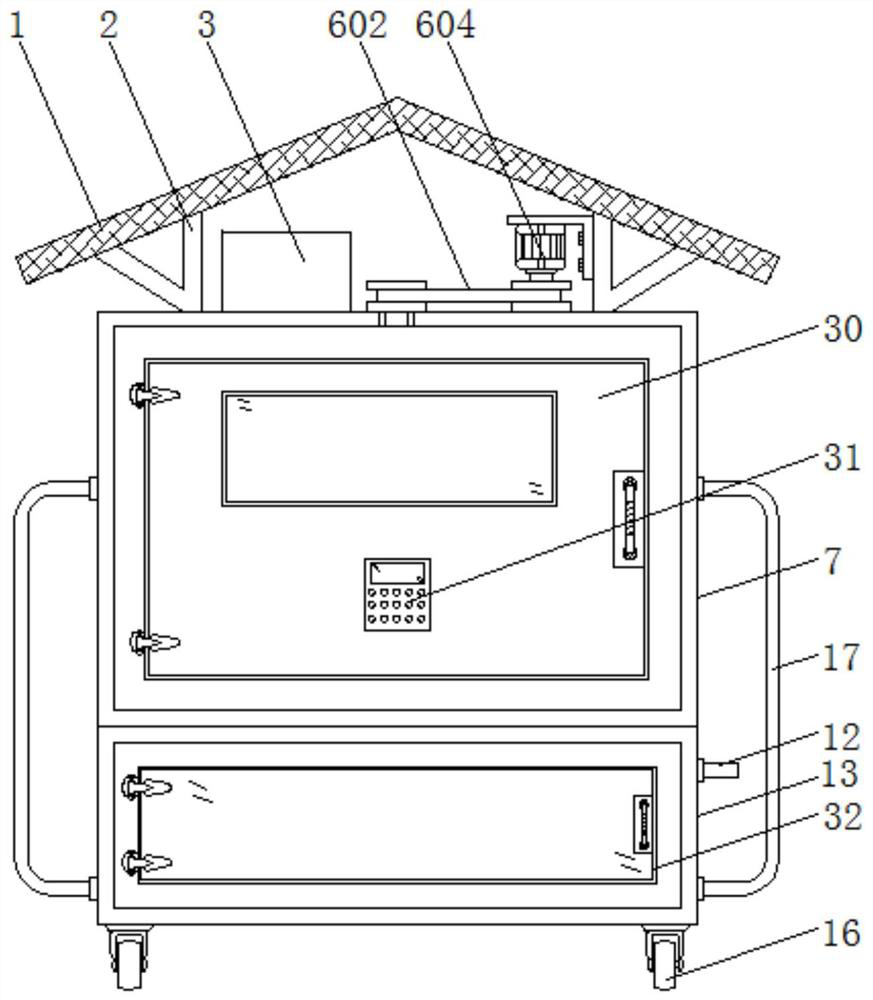

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0032] The present invention provides a technical solution: a spray cleaning device for the production of quartz ceramic products, including a water tank 13, a water pump 14 is installed at the center of the bottom of the inner cavity of the water tank 13, and rollers 16 are installed at the four corners of the bottom of the water tank 13 , and the outer wall of the roller 16 is provided with brake pads, which is convenient to use the roller 16 to move the position of the device at will, and the brake pads are set to facilitate fixing the device and avoid rolling during use (see figure 1 );

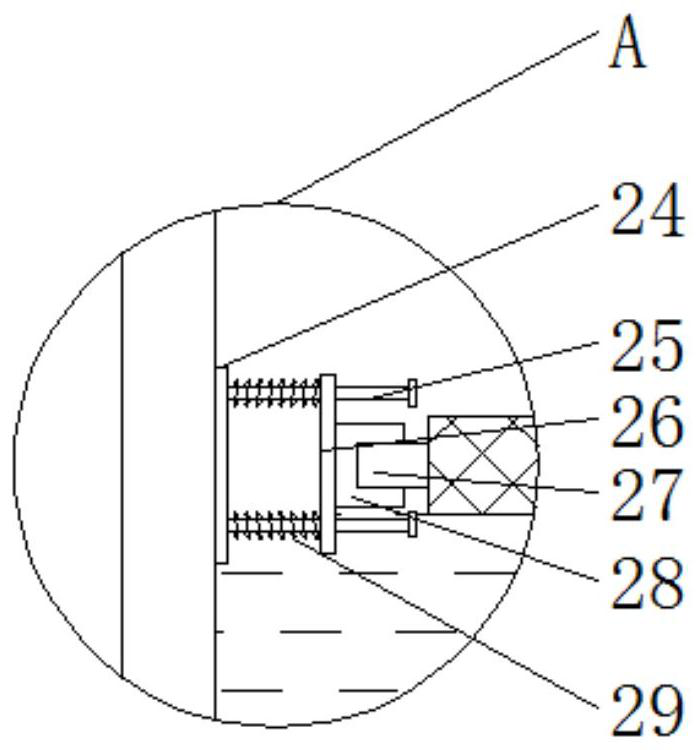

[0033] The center of the water tank 13 inner cavity is horizontally equipped with a filter screen 15, and the left and right ends of the filter screen 15 are symmetrically provided with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com