Preparation method for 800 MPa low-temperature resistant high strength steel

A low-temperature-resistant, high-strength steel technology, applied in the field of steel rolling, can solve problems such as poor shape of low-temperature-resistant high-strength steel plates, improve head and tail warpage and waves, and achieve the effect of efficient energy utilization

Active Publication Date: 2020-09-25

SHOUGANG CORPORATION

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the deficiencies of the above-mentioned prior art, the present invention provides a preparation method of 800MPa low-temperature-resistant high-str

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

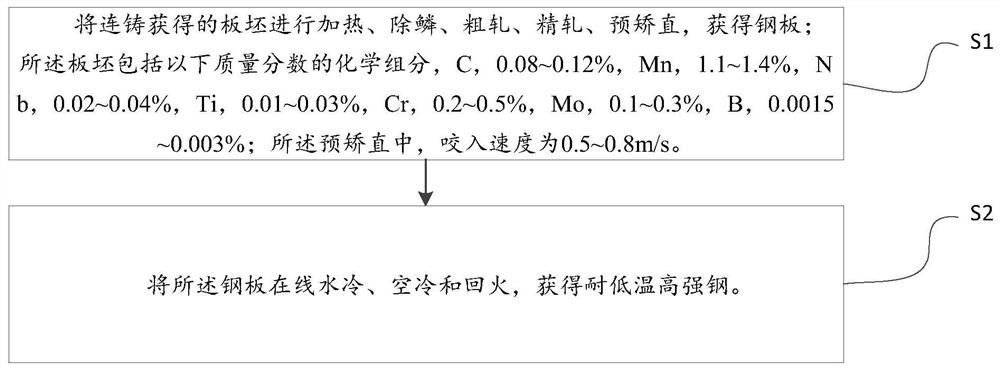

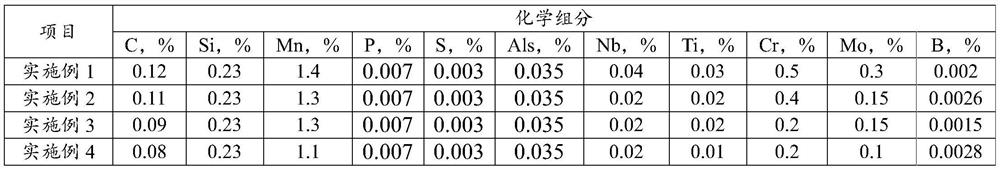

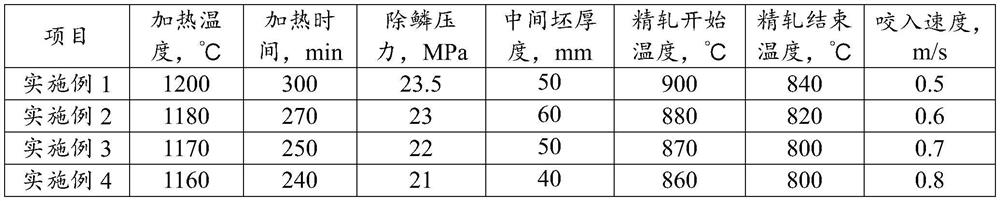

The invention discloses a preparation method for 800 MPa low-temperature resistant high strength steel. The method comprises the steps of heating, descaling, rough rolling, finish rolling and pre-straightening of a plate blank obtained through continuous casting; the plate blank comprises the following chemical components, by mass: 0.08%-0.12% of C, 1.1%-1.4% of Mn, 0.02%-0.04% of Nb, 0.01%-0.03%of Ti, 0.2%-0.5% of Cr, 0.1%-0.3% of Mo and 0.0015%-0.003% of B; in the pre-straightening process, the bite speed is 0.5-0.8 m/s; and a steel plate is water-cooled, air-cooled and tempered on line toobtain the low-temperature resistant high strength steel. According to the preparation method, the hot rolled steel plate is directly subjected to quenching treatment, and reheating after cooling is not required; the waste heat utilization of the steel plate is achieved, and energy sources are saved; and the production cost is reduced.

Description

technical field [0001] The invention belongs to the technical field of steel rolling, and in particular relates to a preparation method of 800MPa low-temperature-resistant high-strength steel. Background technique [0002] Low-temperature-resistant high-strength steel belongs to high-strength welded structural steel, with a thickness of 8-120mm in general, and can be widely used in coal mining machinery, construction machinery and other fields. In order to ensure the strength of the product, this low-temperature-resistant high-strength steel is generally delivered in a quenched and tempered state. Its conventional production process is that the slab obtained by continuous casting is heated by a heating furnace-dephosphorization-rolling-steel plate cooling-steel plate offline quenching-steel plate tempering, this conventional production process is due to production line equipment and layout, etc. After the steel plate rolling process is completed, it is naturally cooled off ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/04C22C38/26C22C38/28C22C38/22C22C38/32C21D8/02C21D1/18

CPCC22C38/04C22C38/26C22C38/28C22C38/22C22C38/32C21D8/0226C21D1/18C21D2211/002C21D2211/008C21D2211/005

Inventor 路士平顾林豪田鹏王志勇李群何元春黄乐庆张学峰狄国标魏运飞邹扬王凯凯

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com