Preparation method of blast furnace slag-based microcrystal luminescent glass

A luminescent glass and slag-based technology, which is applied in the field of direct utilization of luminescent materials and metallurgical solid waste, can solve the problems of difficult to meet the color rendering index of LED lighting, many preparation processes, and heavy, etc., to achieve efficient energy utilization and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 500g blast furnace slag and 10g H 3 BO 3, ground into powder, placed in a graphite crucible, heated to 1360°C in a box-type resistance furnace, kept for 2 hours, sampled in a hot state, in a liquid state, quenched in cold water, cooled to room temperature, dried at 60°C, and ground into CMAS Glass powder (A powder) is set aside.

Embodiment 2

[0025] Weigh 500g blast furnace slag and 10g NaNO 3 , ground into powder, placed in a graphite crucible, heated to 1320°C in a box-type resistance furnace, kept for 2 hours, sampled in a hot state, in liquid state, quenched in 10% NaCl solution, cooled to room temperature, dried at 60°C, Grind it into CMAS glass powder (B powder) for later use.

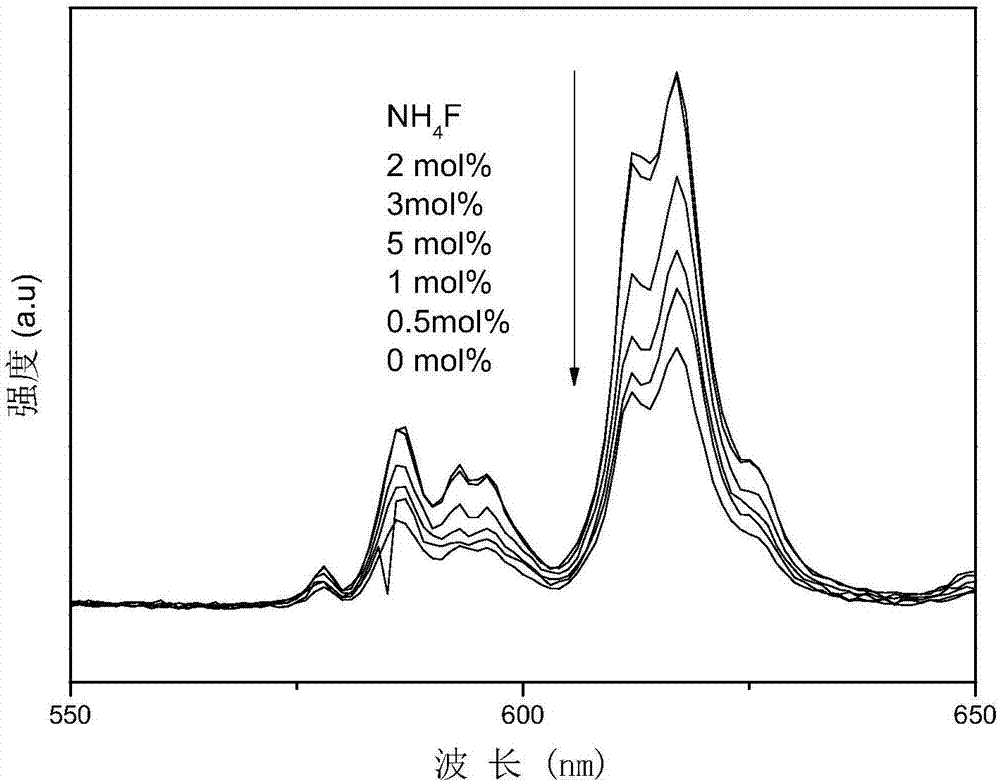

[0026] 2. Preparation of CMASR microcrystalline luminescent glass

Embodiment 3

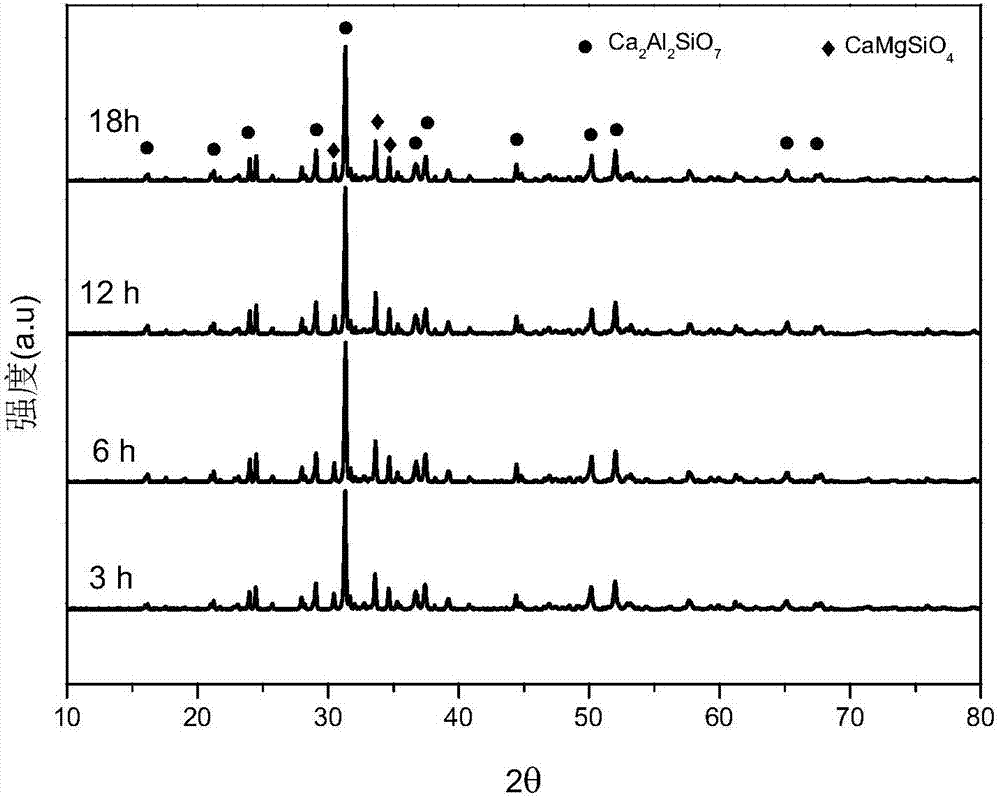

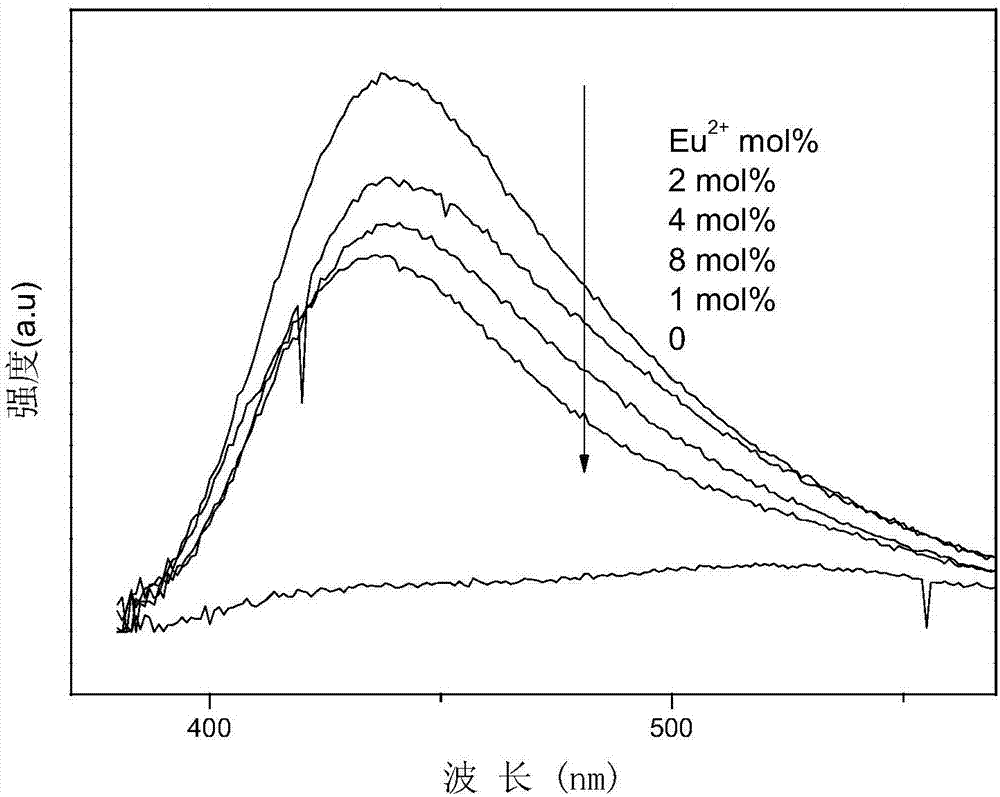

[0028] Weigh 3g CMAS glass powder (A powder), doped with 1mol% Eu 2 o 3 After grinding, put it in a graphite crucible, heat it in a resistance furnace at a rate of 10 °C / min to 600 °C, keep it for 1 hour, then heat it at a rate of 5 °C / min to 1200 °C, keep it at a rate of 6 hours, and then cool it to room temperature with the furnace. Sampling and grinding to obtain CMASE red-emitting microcrystalline luminescent glass powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com