A method for detecting abnormal behavior of on-site process behavior in the manufacturing industry

A detection method and manufacturing technology, applied in the direction of program control, general control system, control/adjustment system, etc., can solve the problems of unstable abnormal detection and prediction results, large data space and time costs, and large storage space, etc., to achieve Unmanned or less-manned operation, improving production efficiency and safety factor, and realizing the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

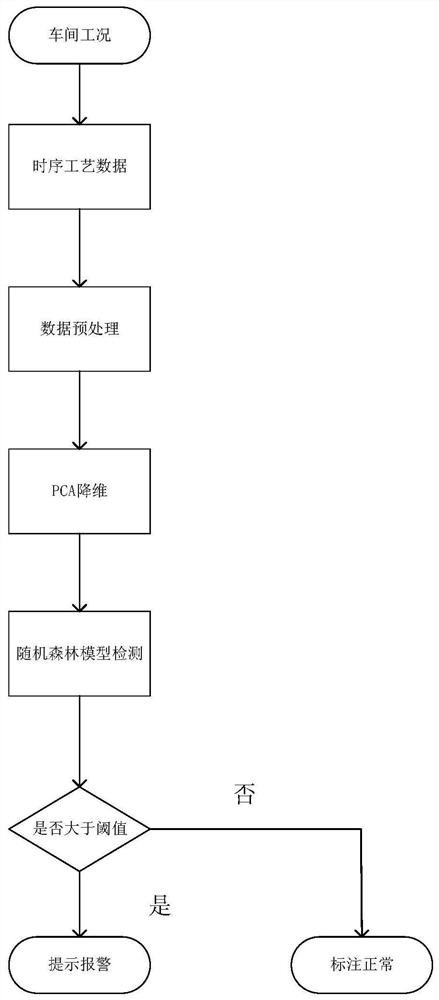

[0027] The present invention comprises the following steps:

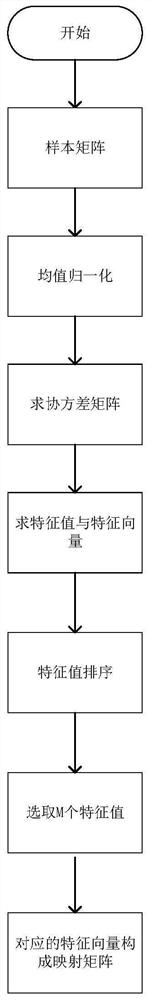

[0028] 1. Perform data preprocessing on process data, visualize data missing values, and perform noise reduction processing on data, use PCA method to reduce dimensionality of data, similar features are merged, reduce the number of features, and reduce data dimension. The projection error is minimized, and the transformed data dimensions are new, which is beneficial to prevent the occurrence of overfitting. The PCA dimensionality reduction steps are as follows:

[0029] 1a) Perform mean normalization on continuous raw data to ensure that the data magnitude of each dimension is the same.

[0030] 1b) Find the covariance matrix of the features:

[0031]

[0032] Among them, cov means covariance, Xi is the i-th eigenvalue, Yi is the i-th predicted value, are feature variance and prediction variance respectively; n is the number of features, and i is each data i=1,2,...n to be substituted into the calculation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com