A laser cladding device

A laser cladding and mounting frame technology, which is applied in the coating process and coating of metal materials, can solve the problems of low cladding layer dilution, affecting cladding quality, strong bonding force, etc., and eliminate uneven cladding , The cladding operation is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

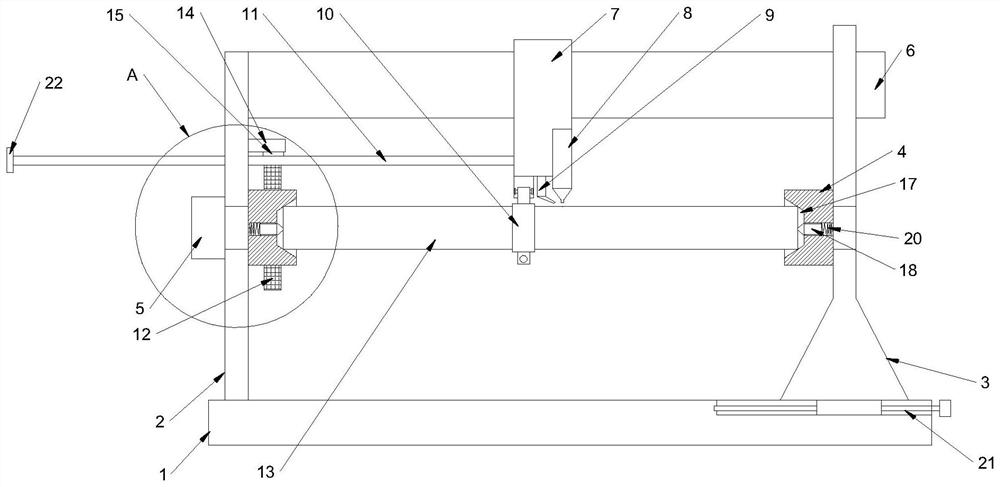

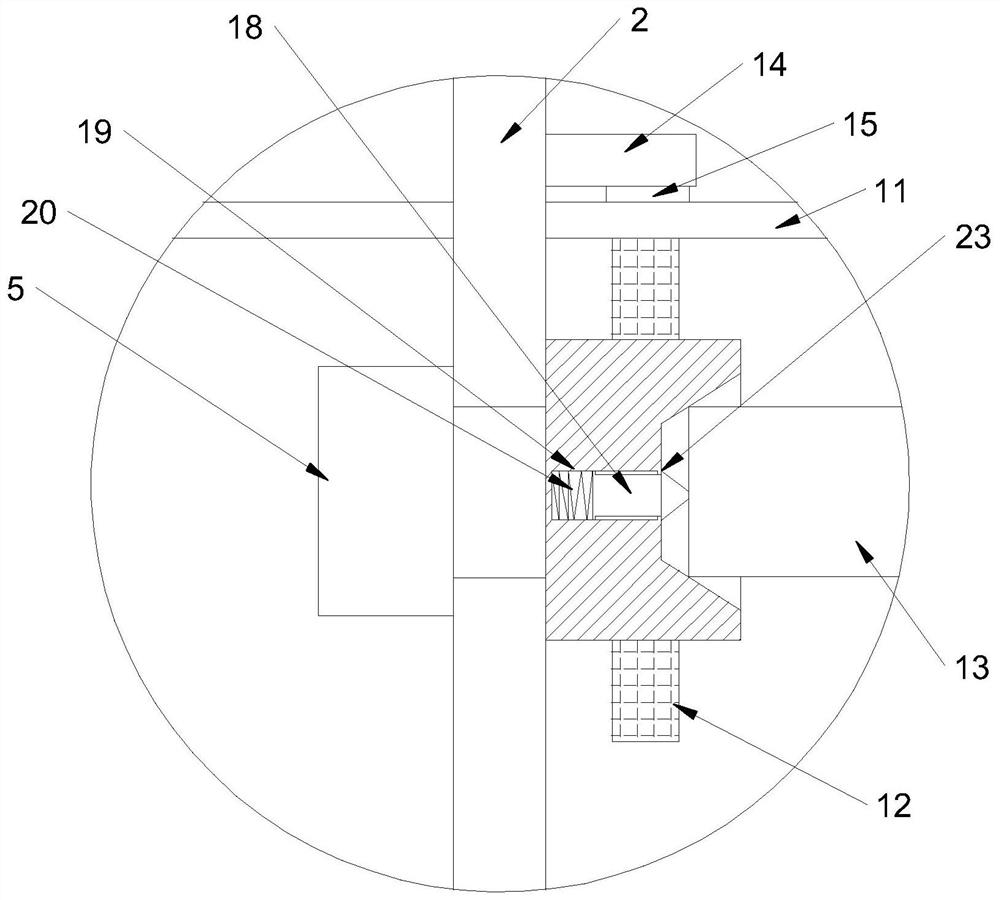

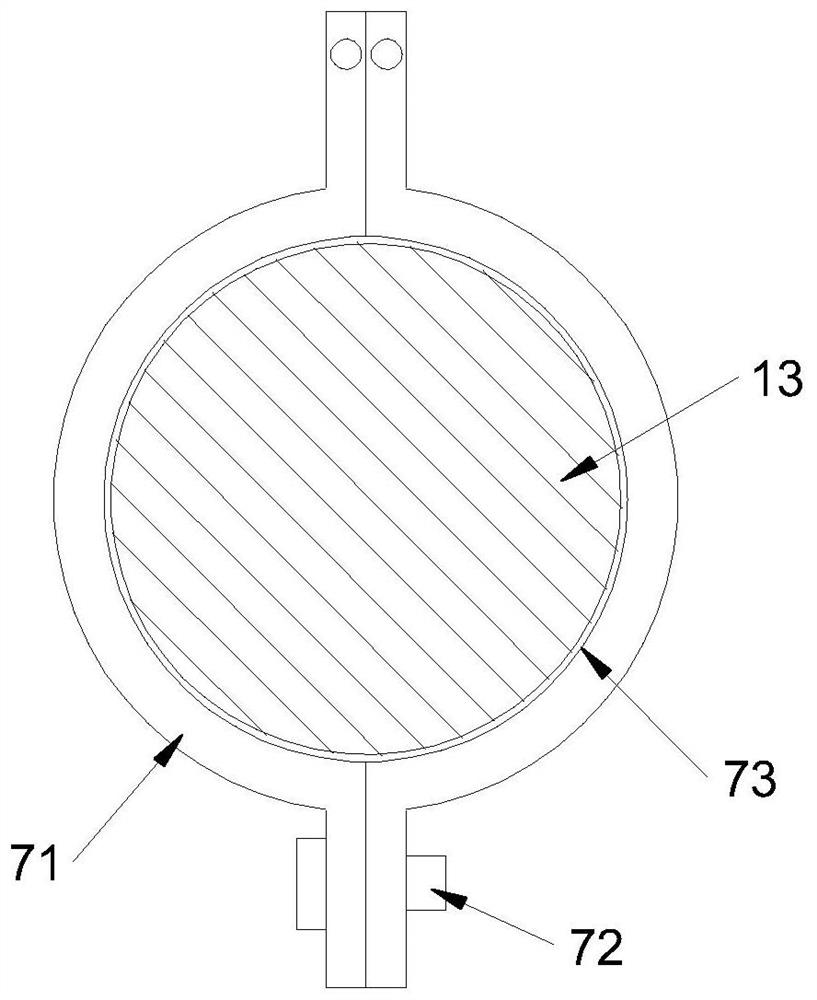

[0021] combine Figure 1 to Figure 5 The shown laser cladding device, in this embodiment, includes a base 1, a mounting frame, a fixture body 4, a rotating motor 5, a guide frame 6, a carriage 7, a laser cladding head 8, a powder feeding tube 9, Supporting hoop 10, guide arc plate 11 and annular threaded block 12; two sets of mounting brackets are arranged on the base 1, and two sets of clamp bodies 4 are respectively rotatably connected to the two sets of mounting brackets, and can be installed on one of the two sets of mounting brackets The two ends of the shaft workpiece 13 are rotated under the drive of the rotating motor 5 on the upper side; the guide frame 6 is horizontally erected between the two sets of mounting frames, and the sliding frame 7 is horizontally slidably connected to the guide frame 6, and the laser cladding head 8 The powder feeding tube 9 for feeding powder on the surface of the workpiece 13 that can be aligned with the laser cladding head 8 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com