Pneumatic metering pump and its measuring method

A metering pump and metering cavity technology, applied in the field of metering pumps, can solve problems affecting normal work, changes in metering accuracy, and wear, and achieve long-term reliable work, high-precision metering, and accurate metering data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

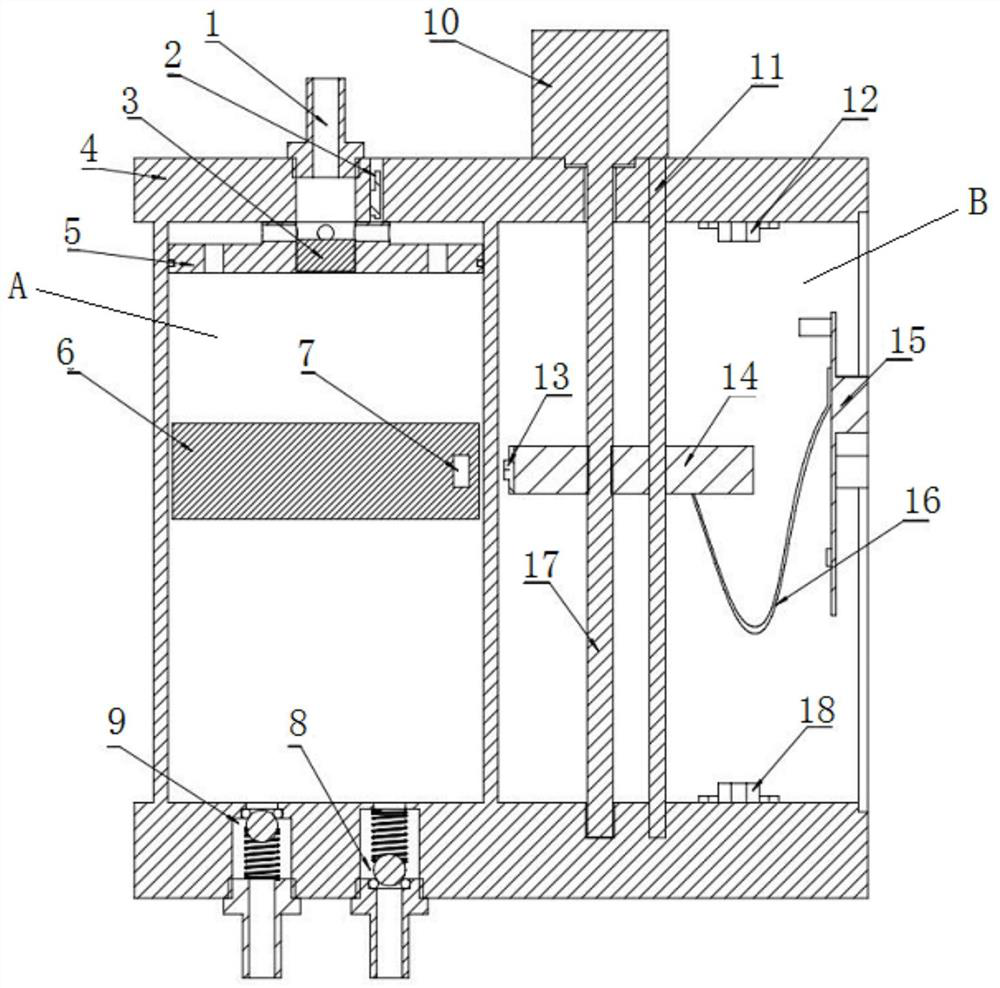

[0029] In order to make those skilled in the art understand the technical means implemented by the present invention, the present invention will be further described below with reference to the specific drawings.

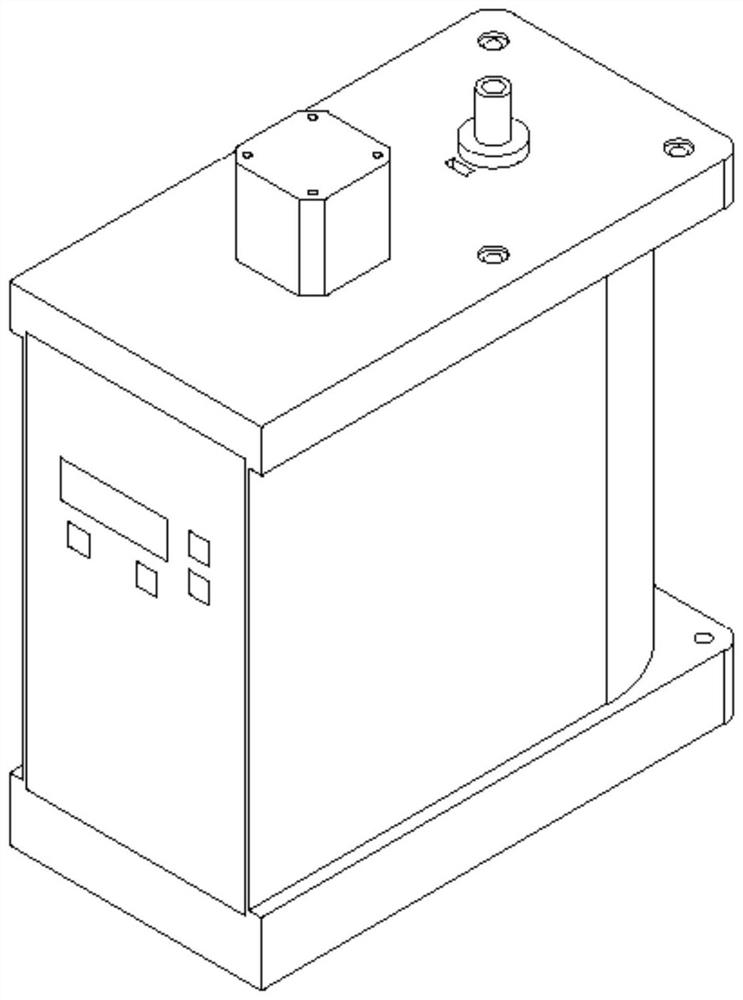

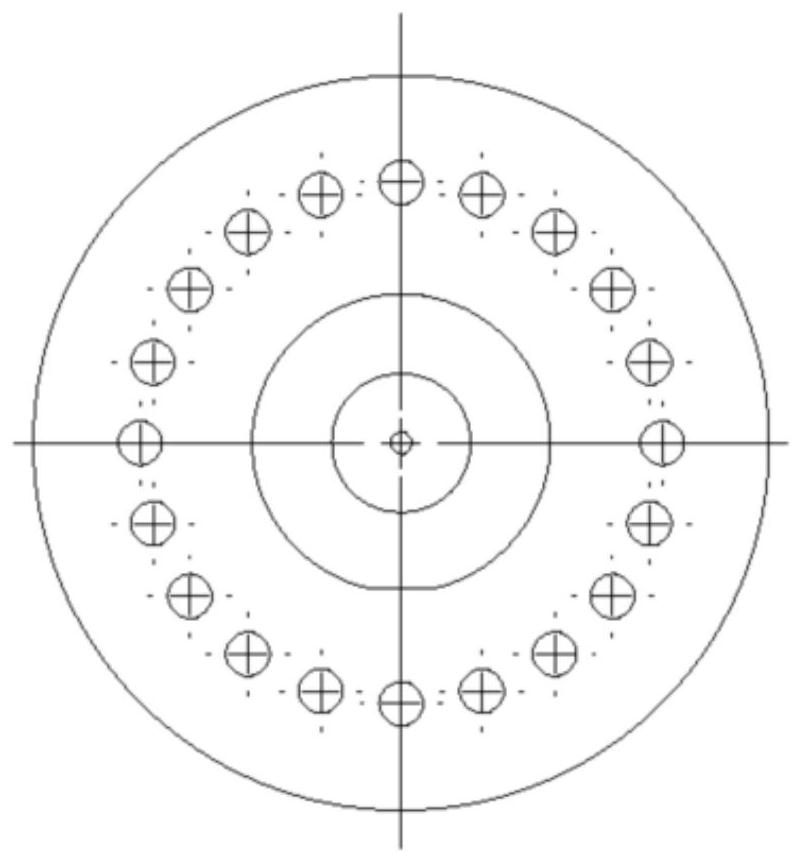

[0030] like Figure 1-5 As shown in the figure, a pneumatic metering pump of the present invention includes a pump body, and a metering chamber A and a detection chamber B are arranged inside the pump body. It is characterized in that: the upper end of the metering chamber A is provided with an air inlet and outlet 1 , the lower end is provided with a liquid inlet and a liquid outlet, and a liquid inlet check valve 8 and a liquid outlet check valve 9 are respectively installed on the liquid inlet and the liquid outlet, and a freely movable liquid level float is arranged inside the metering chamber A 6. The side of the liquid level float 6 close to the detection chamber is provided with a magnetic steel 7; the detection chamber B is equipped with a stepper motor 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com