An anti-shock and vibration-absorbing support based on hydraulic principle and its working method

A technology of working method and hydraulic principle, applied in vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., can solve the problems of shock, overall vibration of experimental device, deviation of results, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

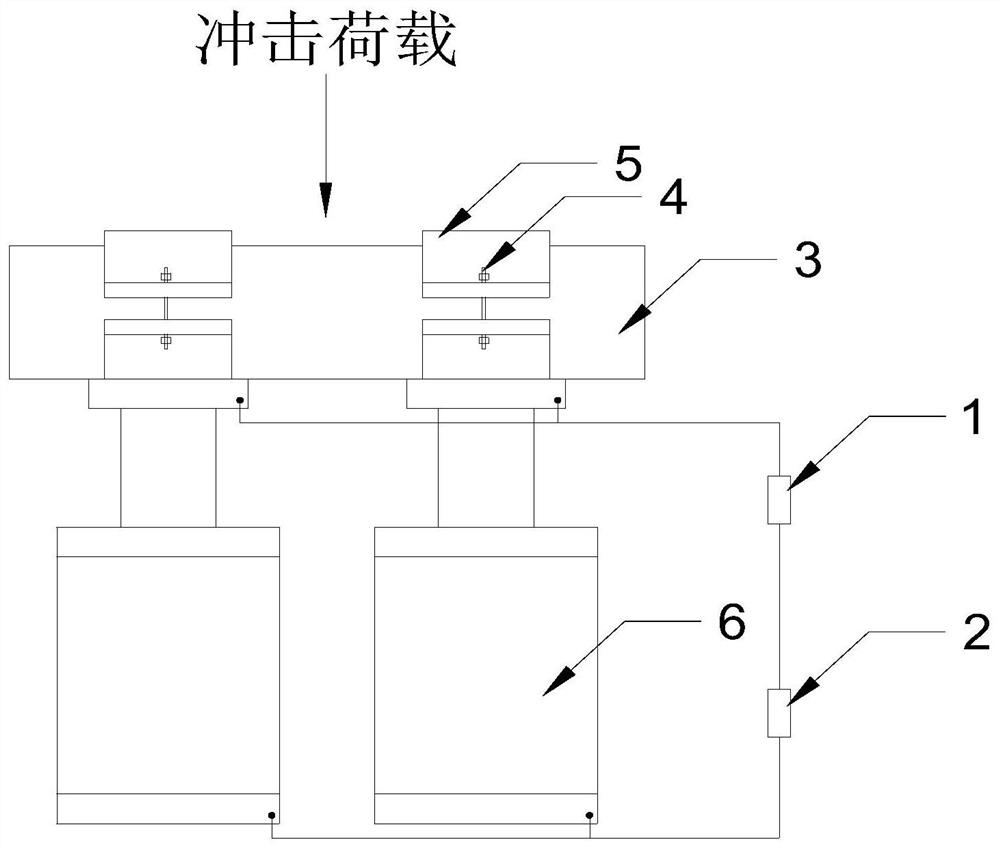

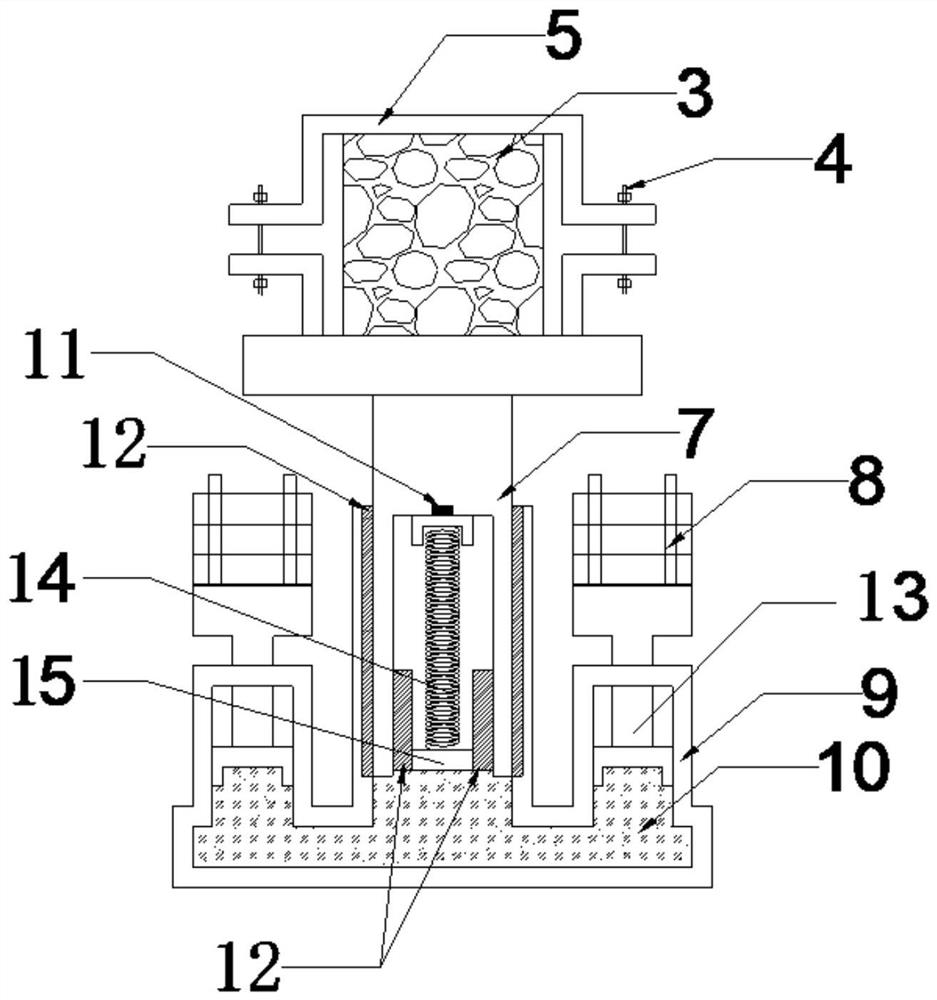

[0024] see figure 1 and figure 2 , an anti-shock and vibration-absorbing support based on hydraulic principles, including a cylinder 9 filled with hydraulic oil 10, a piston body 7 and a plurality of anti-shock and vibration-absorbing supports 6 are arranged on the upper part of the cylinder 9, The top of the anti-shock and vibration-absorbing support body 6 is provided with a mass block 8, which can be replaced by mass blocks of different weights. The bottom of the mass block 8 is provided with a connecting rod 13, and the bottom of the connecting rod 13 goes deep into the cylinder body 9. The connecting rod 13 The up and down movement is controlled by the hydraulic oil 10, the piston body 7 is provided with a buffer end 15, a spring 14 is arranged between the buffer end 15 and the piston body 7, an electromagnet group 12 is arranged on the piston body 7, and the to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap