Mechanical seal following floating

A technology of mechanical seals and seals, which is applied in the field of follow-up floating mechanical seals, can solve the problems of large radial and axial fluctuations between the shell and the shaft, oil leakage, etc., and achieve reliable sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

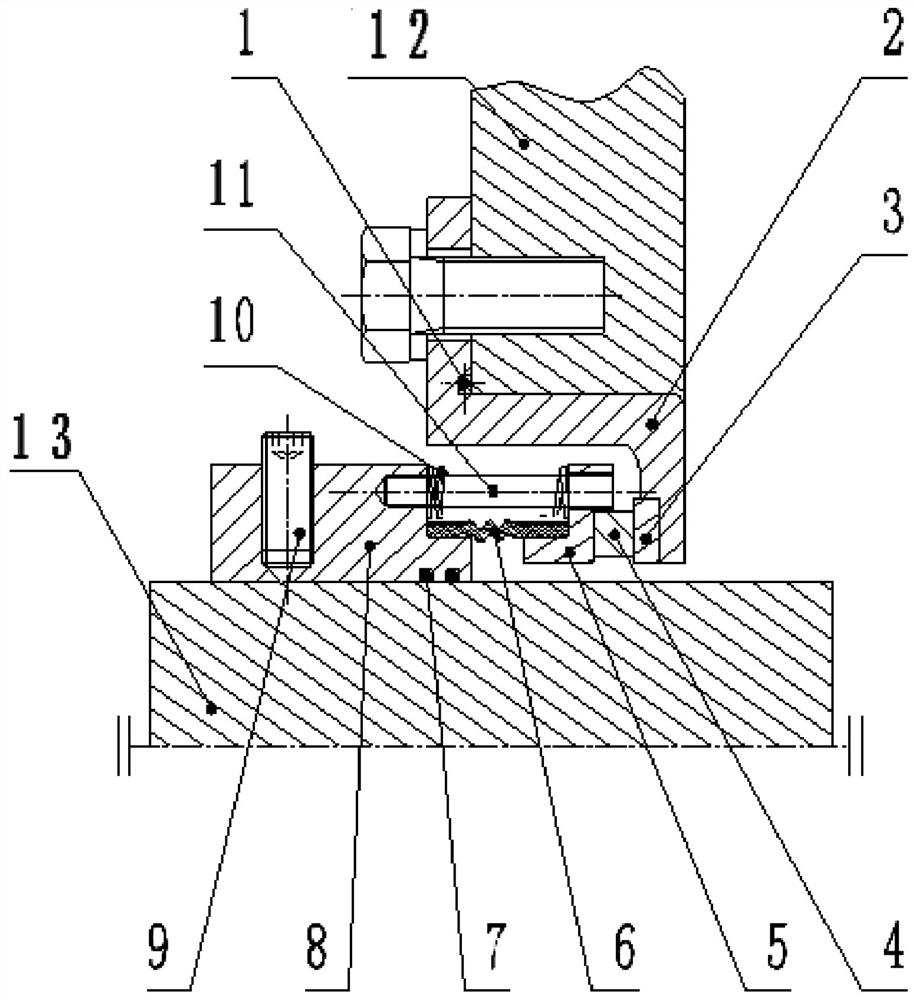

[0018] In order to further disclose the technical solutions of the present invention, the following will be described in detail in conjunction with the accompanying drawings of the description:

[0019] The invention includes: fixed seat A (2), end face seal D (3), seal (1) of fixed seat A, end face seal B (5), end face seal E (4) seat C, fixed seat C (8), the axial seal F (7), the rubber sleeve (6), the set screw (9), the spring (10) and the guide shaft (11), the seal (1) of the fixed seat A (2) ) is sandwiched between the shell (or barrel 12) and the fixing seat A (2), the fixing seat A is fixed on the shell or barrel by bolts, and the fixing seat C (8) is fixed on the On the shaft (13), the guide shaft is installed on the outside of the annular groove formed by the fixed seat C (8) and the end face seal seat B (5), and one end is fixed on the fixed seat C (8) by threads, and the spring (10) sets On the guide shaft (11), the other end of the guide shaft is inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com