Mask alignment mark combination, mask alignment system, photoetching device and photoetching method

An alignment mark and mask alignment technology, applied in the field of lithography, can solve problems such as the need to improve the accuracy and the measurement error of the mask alignment position, and achieve the effect of improving the measurement accuracy of the mask alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

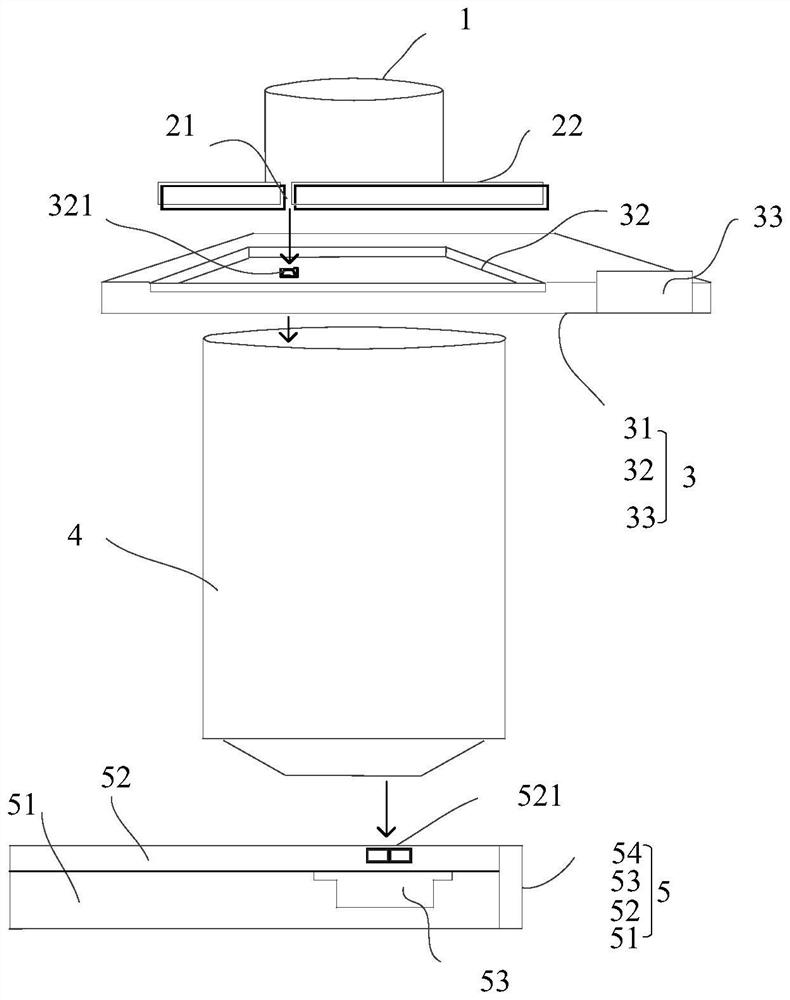

Embodiment 1

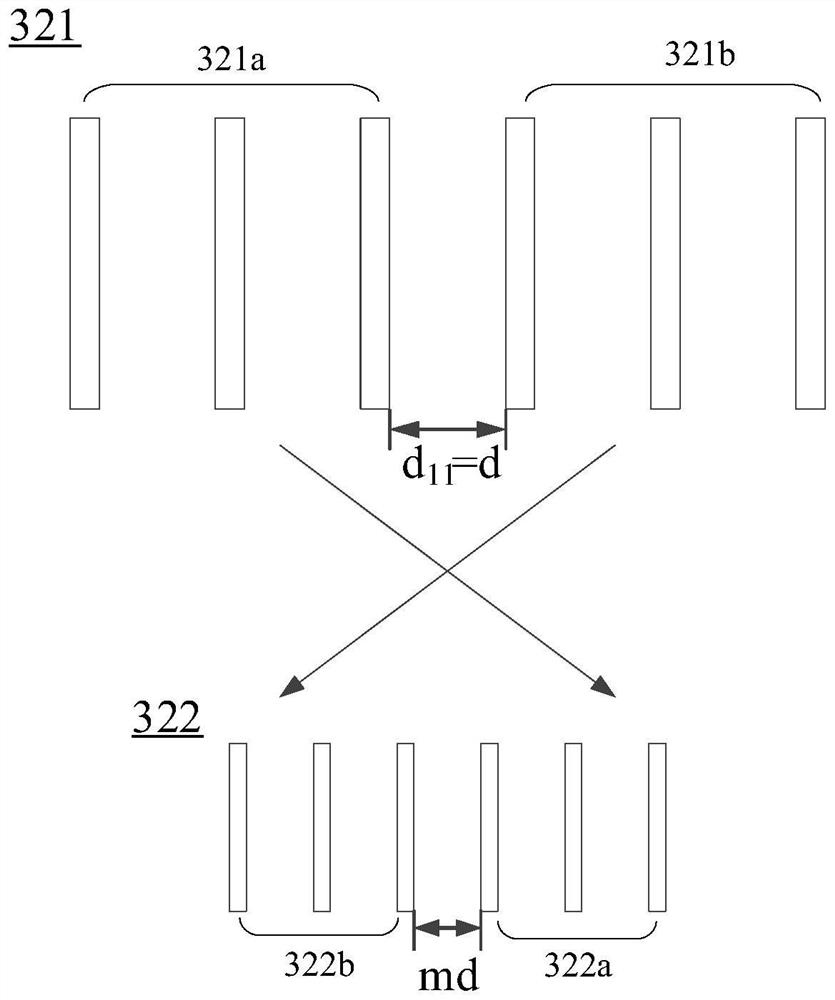

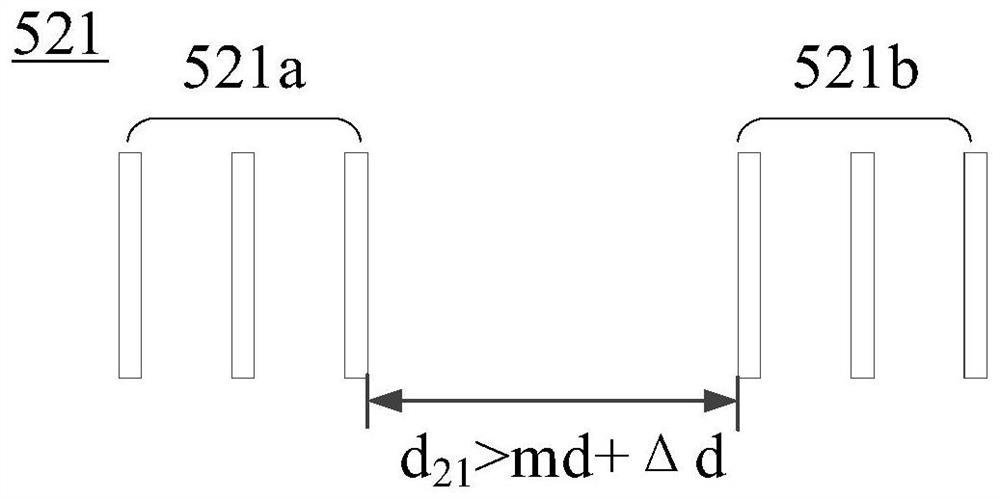

[0045] In this embodiment, the first alignment mark branch 321 and the second alignment mark branch 521 both include two sets of gratings for illustration. Such as figure 2 As shown, the first alignment mark branch 321 includes two groups of gratings 321a, 321b, and the interval between the two groups of gratings 321a, 321b is the first width dimension d 11 , let d 11 =d, wherein, d is a constant, and the projection assembly 4 projects the transmission image of the first alignment mark branch 321 onto the surface of the workpiece stage reference plate 52 to form two non-overlapping aerial images 322a , 322b, wherein, aerial image 322a is the aerial image that grating 321a produces, aerial image 322b is the aerial image that grating 321b produces, because the projection magnification of projection assembly 4 is m, aerial image 322a, 322b are two groups of gratings 321a, 321b The ratio is reduced, so the width dimension of the interval between the spatial images 322a and 322b...

Embodiment 2

[0059] Such as Figure 6-Figure 8 As shown, the difference from Embodiment 1 is that in this embodiment, both the first alignment mark branch 321 and the second alignment mark branch 521 include more than two groups of gratings, for example, N groups (N greater than or equal to 3). Such as Figure 6 As shown, the first width dimension of the interval between each group of gratings in the first alignment mark branch 321 is d 11 =d, after being projected by the projection component, N aerial images 322 are formed, and the space between each aerial image is md. Figure 7 , the second alignment mark branch 521 also includes N groups of gratings, and the interval between each group of gratings is the second width dimension d 21 , the third width dimension d 22 ...the n+1th width dimension d 2n , and satisfy the following relation: d 21 >md+1*Δd, d 22 >md+2*Δd...n+1th width dimension d 2n >md+n*Δd, since the size of each aerial image in this embodiment is all equal, so Δd is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com