Anomaly detection in pneumatic system

An abnormality and error detection technology, applied in the direction of pneumatic program control, general control system, error detection/correction, etc., can solve the problems of error monitoring and failure to adopt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

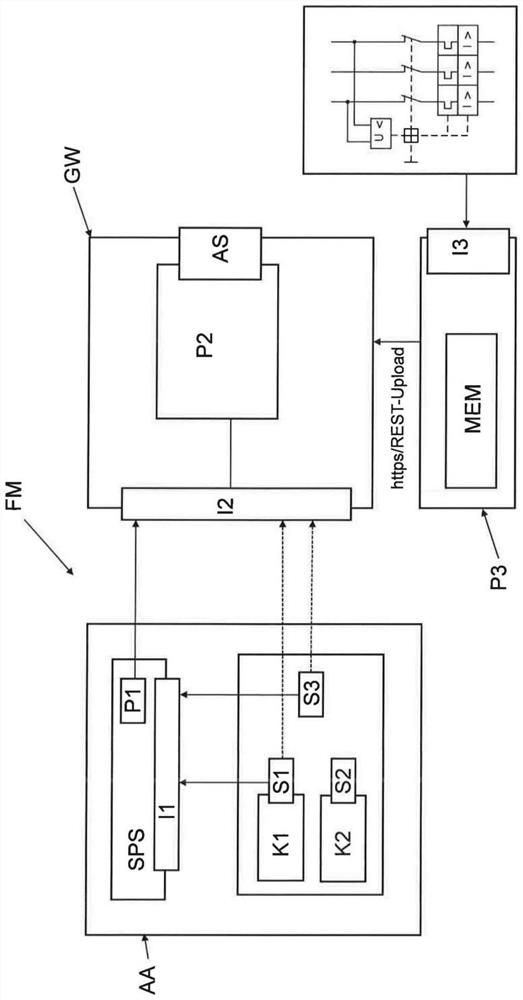

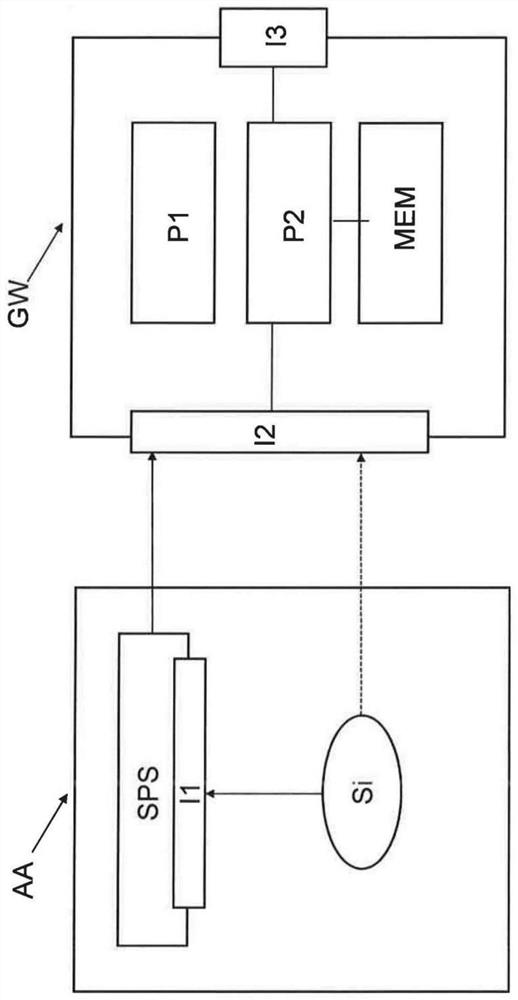

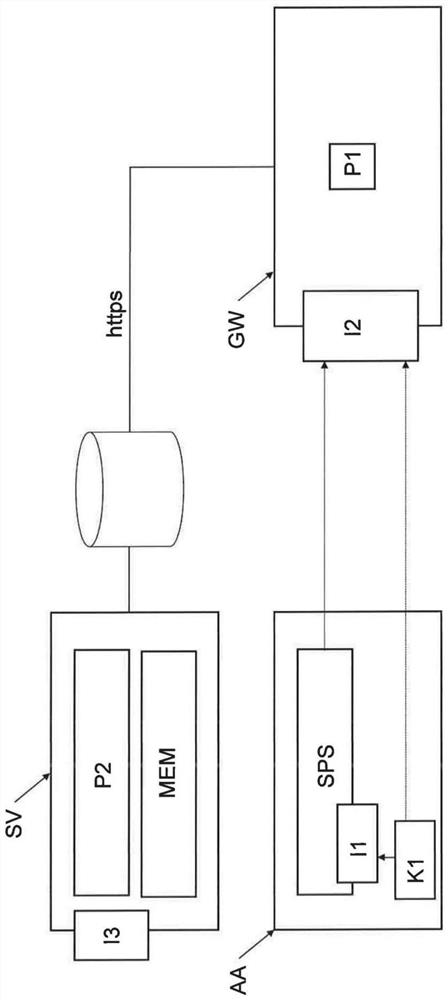

[0076] The present invention is technically used for monitoring a pneumatic system as an example of an automation system or device including various field devices (hereinafter also referred to as components) controlled by a control device such as a PLC. In particular, errors should be identified in good time, and preferably at some point in time before individual components fail or cause errors in the device. For this purpose, the error detection module will be used, and the following will be compared to the figure 1 This error detection module is explained in more detail.

[0077] The invention has the advantage that early error detection of complex, multi-component, preferably pneumatic automation systems is possible despite the fact that only little measurement data is available and can be similarly operated with a minimum of sensor systems. In particular, error positioning can be provided despite the use of only two digital sensors and one switching command, especially fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap