Depainting device for enameled wire

An enameled wire and paint stripping technology, which is applied in coil manufacturing and other directions, can solve problems such as danger, inability to achieve uniform length, and corrosion of paint strippers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

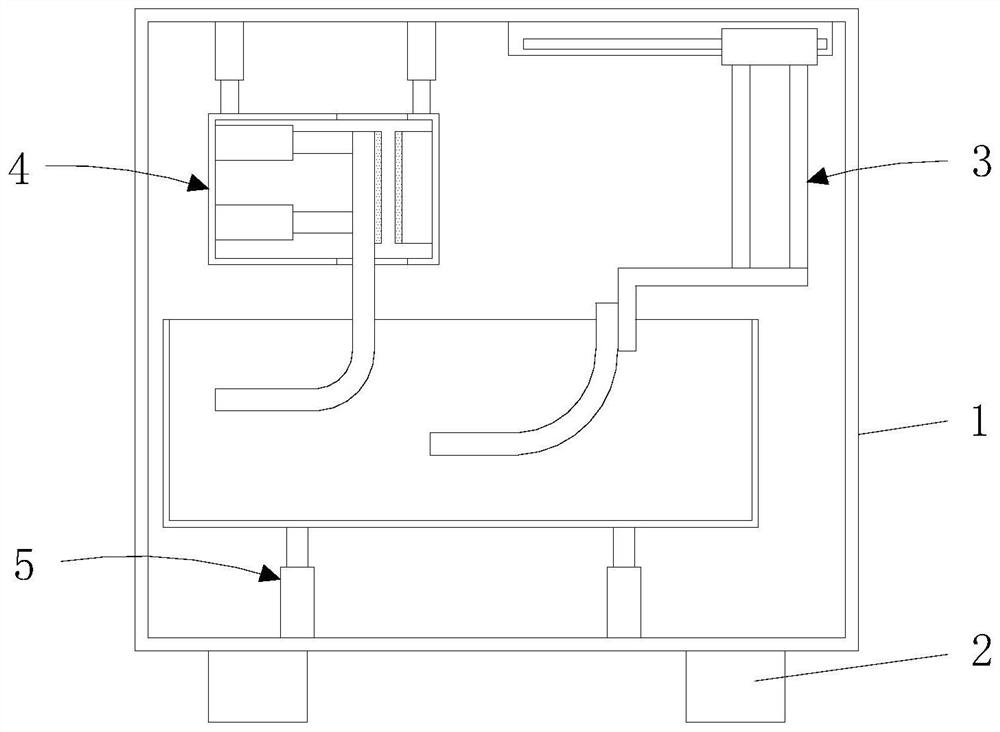

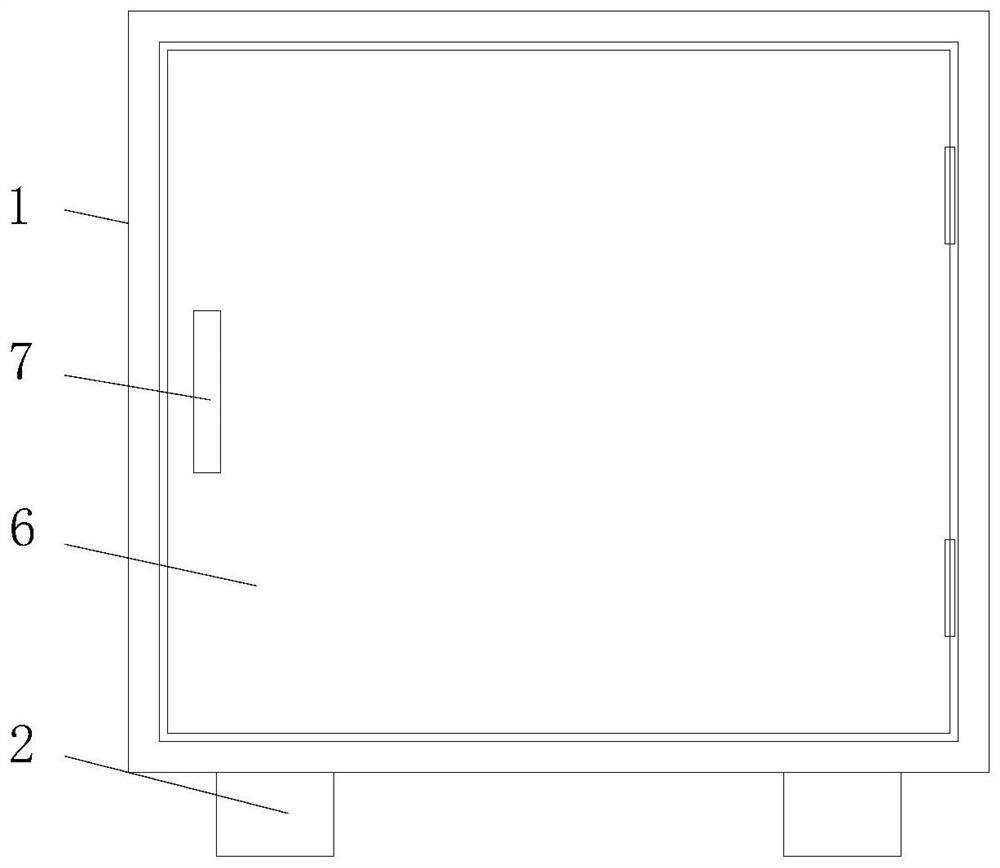

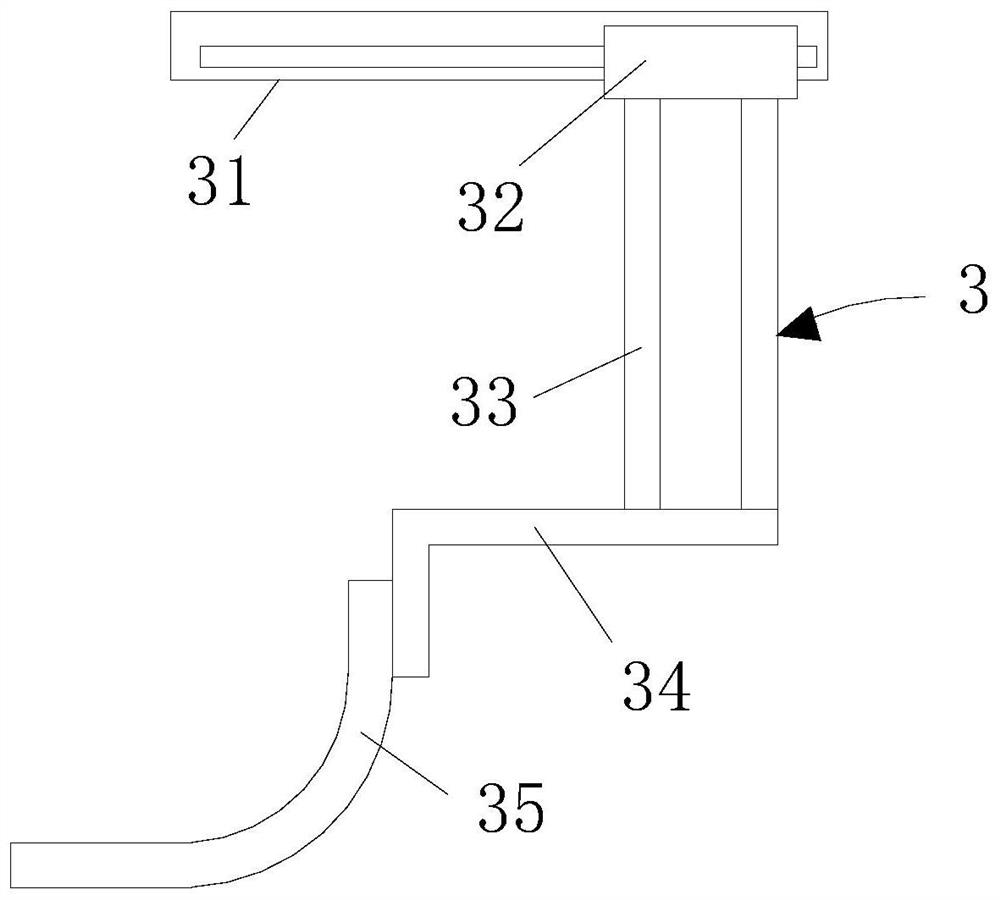

[0022] see Figure 1-5 , an enameled wire stripping device, comprising a housing 1, a supporting leg 2 is fixedly connected around the bottom of the housing 1, and the bottom of the supporting leg 2 is provided with a moving mechanism, and the moving mechanism includes a groove opened at the bottom of the supporting leg 2 , and the fourth electric telescopic rod connected to the middle end of the top of the cavity of the groove, and the bottom of the fourth electric telescopic rod is movably equipped with walking wheels, and its movement method is: people control the fourth electric telescopic rod to extend , so that the walking wheels are in contact with the ground, people push the housing 1 with their hands, so that the walking wheels move, and finally drive the housing 1 to move, the right end of the front surface of the housing 1 is movably connected with a dodge door 6 through a hinge, and the movable The left end of the front surface of the door 6 is fixedly equipped wit...

Embodiment 2

[0024] see Figure 1-5, an enameled wire stripping device, comprising a housing 1, a supporting leg 2 is fixedly connected around the bottom of the housing 1, and the bottom of the supporting leg 2 is provided with a moving mechanism, the moving mechanism is a bracket equipped with traveling wheels, and the bracket The bearing is installed on the bottom of the supporting leg 2, and its movement method is: people push the casing 1 with their hands, so that the walking wheels move, and finally drive the casing 1 to move, and the right end of the front surface of the casing 1 is flexibly connected by a hinge There is dodge door 6, and handle 7 is fixedly installed on the left end of dodge door 6 positive surface, and the material of handle 7 and dodge door 6 is acrylic plate, and the left end of housing 1 inner cavity bottom is provided with lifting mechanism 5, and people first pass handle 7. Open the dodge door 6, then pour the paint remover into the paint remover placement box...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap