Expressway signboard cleaning device

A technology for cleaning devices and highways, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc. The effect of fast speed, wide range and large water outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

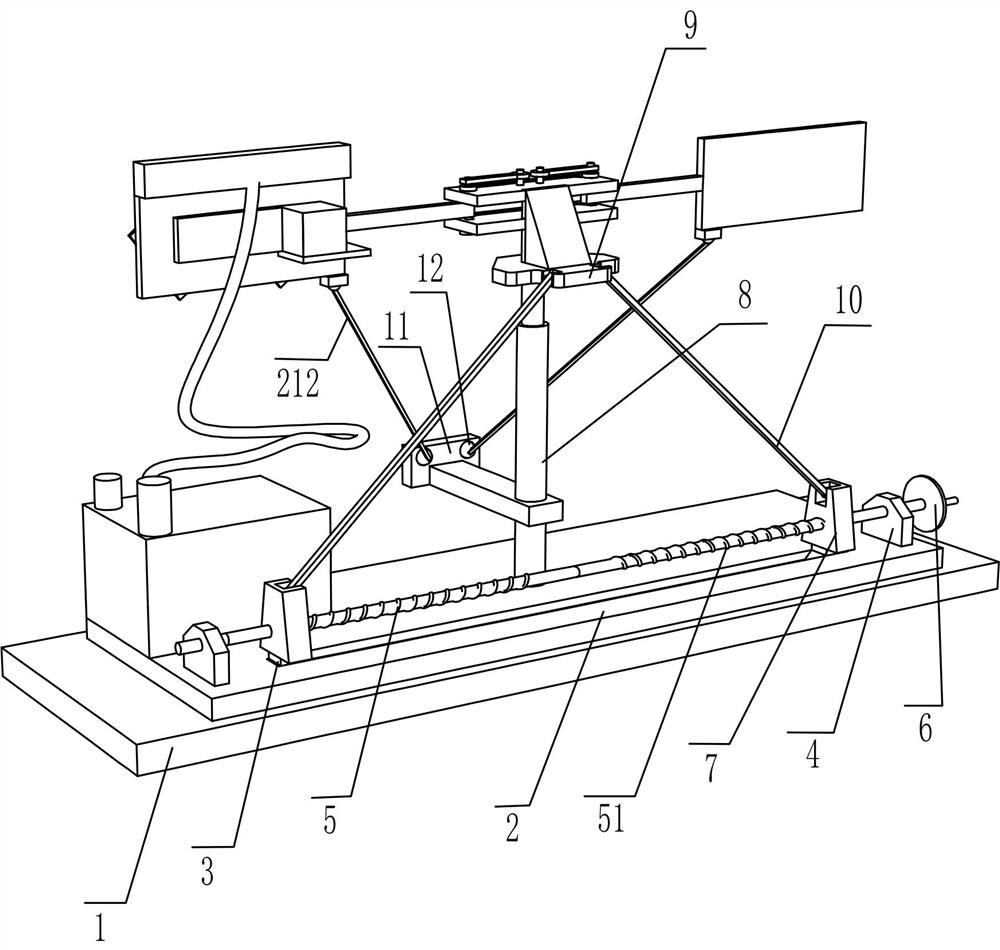

[0023] A cleaning device for expressway signs, such as Figure 1-5 As shown, it includes: mounting plate 1, chute plate 2, sliding block 3, fixed block 4, screw rod one 5, screw rod two 51, hand turntable 6, moving block 7, telescopic rod 8, lifting plate 9, Connecting rod 10, lifting mechanism and cleaning mechanism, the top of the mounting plate 1 is fixedly connected with a chute plate 2, the chute plate 2 is symmetrically slidingly connected with a sliding block 3, and the upper side of the chute plate 2 is fixedly connected with two fixed blocks 4. It is distributed symmetrically. The fixed block 4 on the left is movably provided with a screw rod 5, and the fixed block 4 on the right is movably provided with a screw rod 51, which is symmetrically distributed with the screw rod 5. The right end of the first 5 is fixedly connected with the left end of the second screw 51. The first screw 5 and the second 51 thread are matched with a moving block 7. The bottom of the moving bl...

Embodiment 2

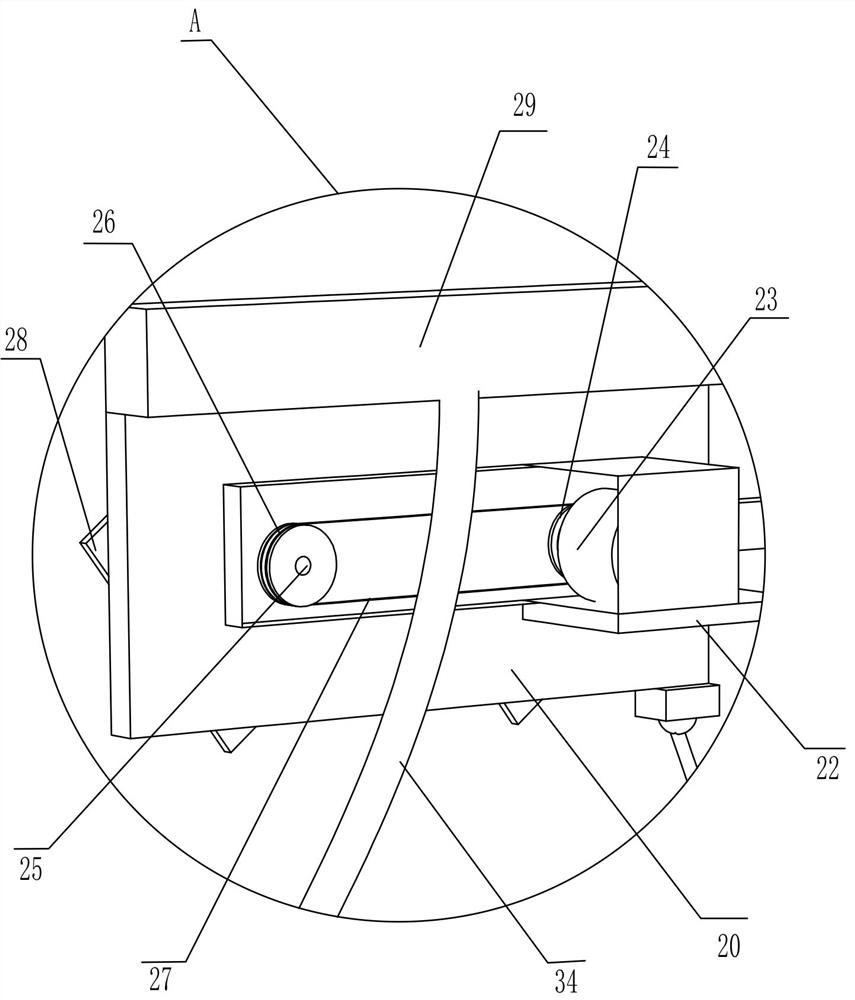

[0026] On the basis of Example 1, such as Figure 1-5 As shown, the lifting mechanism includes a lower universal seat 11, a lower universal ball 12, a fixed seat 13, a lower guide plate 14, a movable rod 15, an upper guide plate 16, a movable rod 17, a guide rod 18, and a clamping plate 19. The cleaning plate 20, the upper universal seat 21, the upper universal ball 211 and the second connecting rod 212, the lower part of the telescopic rod 8 is fixedly connected with the lower universal seat 11, and the rear part of the lower universal seat 11 is symmetrically connected with the lower part. The universal ball 12, the lifting plate 9 is fixedly connected with a fixed seat 13, the middle and rear side of the fixed seat 13 is fixedly connected with a lower guide plate 14, and the sliding groove of the lower guide plate 14 is slidably connected with two movable rods 15 to form Distributed symmetrically, the upper rear side of the fixed seat 13 is fixedly connected with an upper gui...

Embodiment 3

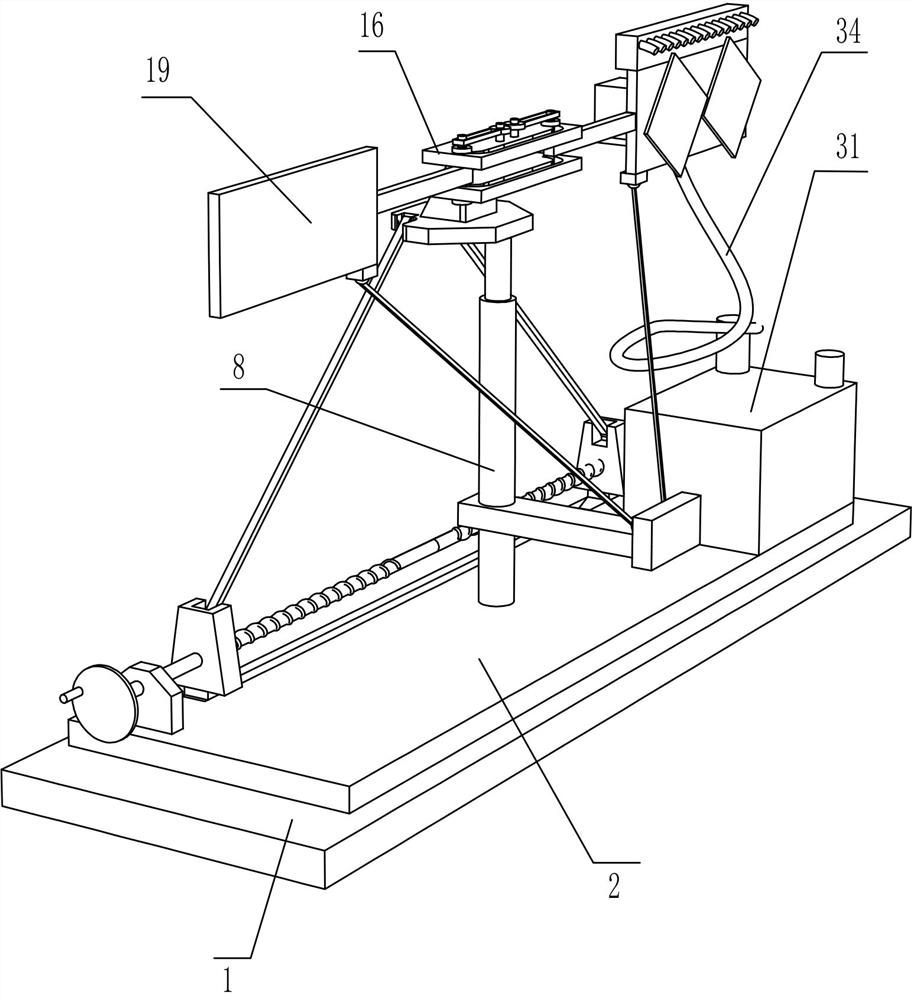

[0031] On the basis of Example 2, such as Figure 3-6 As shown, it also includes a branch box 29, a water spray pipe 30, a water tank 31, a water inlet pipe 32, a water pump 33, and a water pipe 34. The upper part of the cleaning plate 20 is fixedly connected with a branch box 29, and the rear side of the branch box 29 is fixedly connected with water spray The pipes 30 and the water spray pipes 30 are distributed in a linear array. The upper left part of the chute plate 2 is fixedly connected with a water tank 31, the upper part of the water tank 31 is fixedly connected with a water inlet pipe 32, and the front upper side of the water tank 31 is fixedly connected with a water pump 33, The water pump 33 and the branch box 29 are connected by a water pipe 34.

[0032] When delivering water, start the water pump 33 first. The water pump 33 will pump the water from the water tank 31 into the diverter box 29 through the water delivery pipe 34. The water in the diverter box 29 will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com