Quick-assembly tower crane

A technology for quick installation of tower cranes and tower bodies, applied in cranes and other directions, can solve the problems of complex installation and complex structure, and achieve the effects of fast installation, simple operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

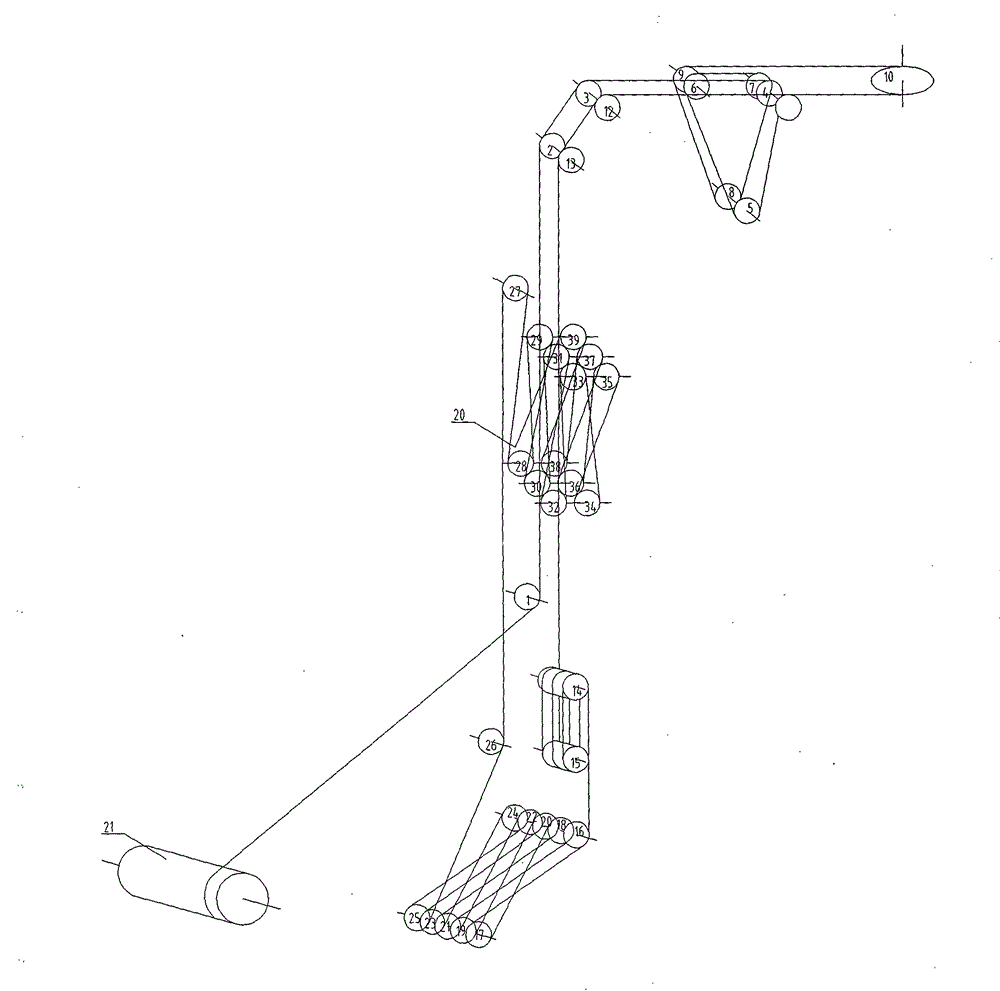

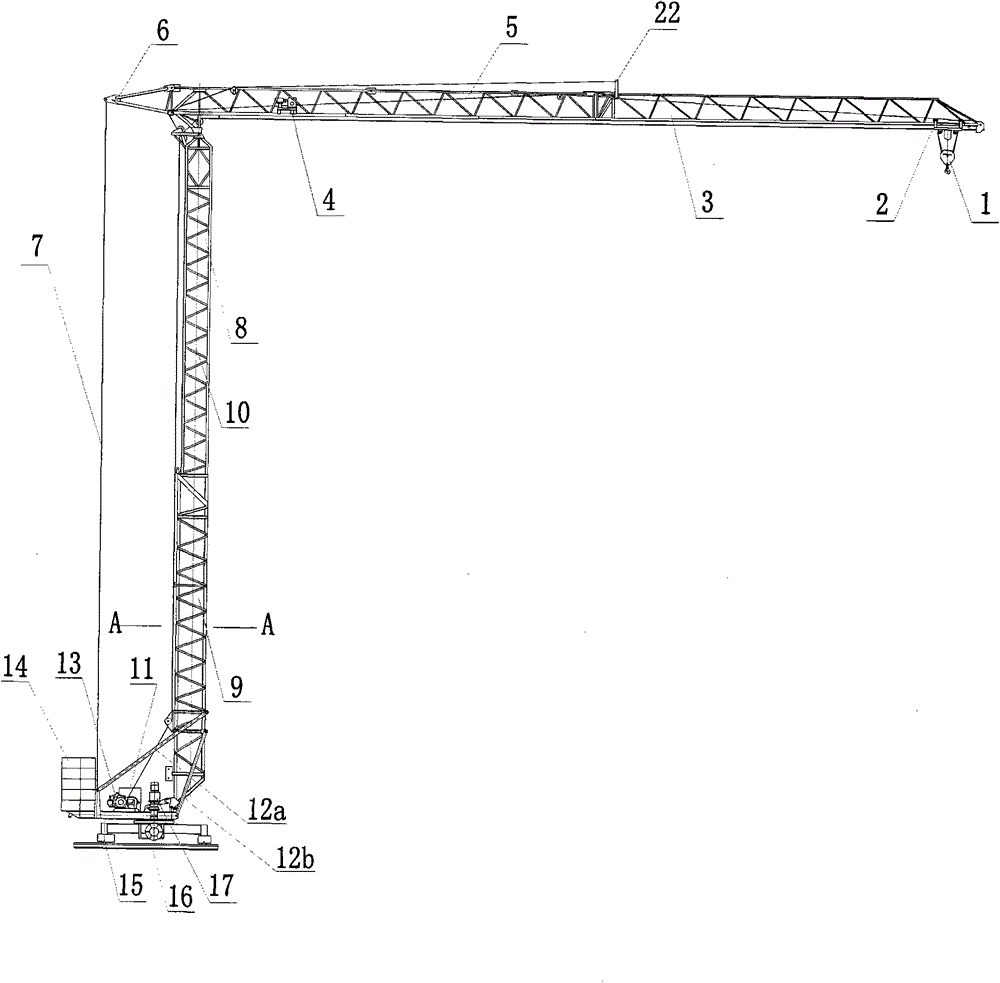

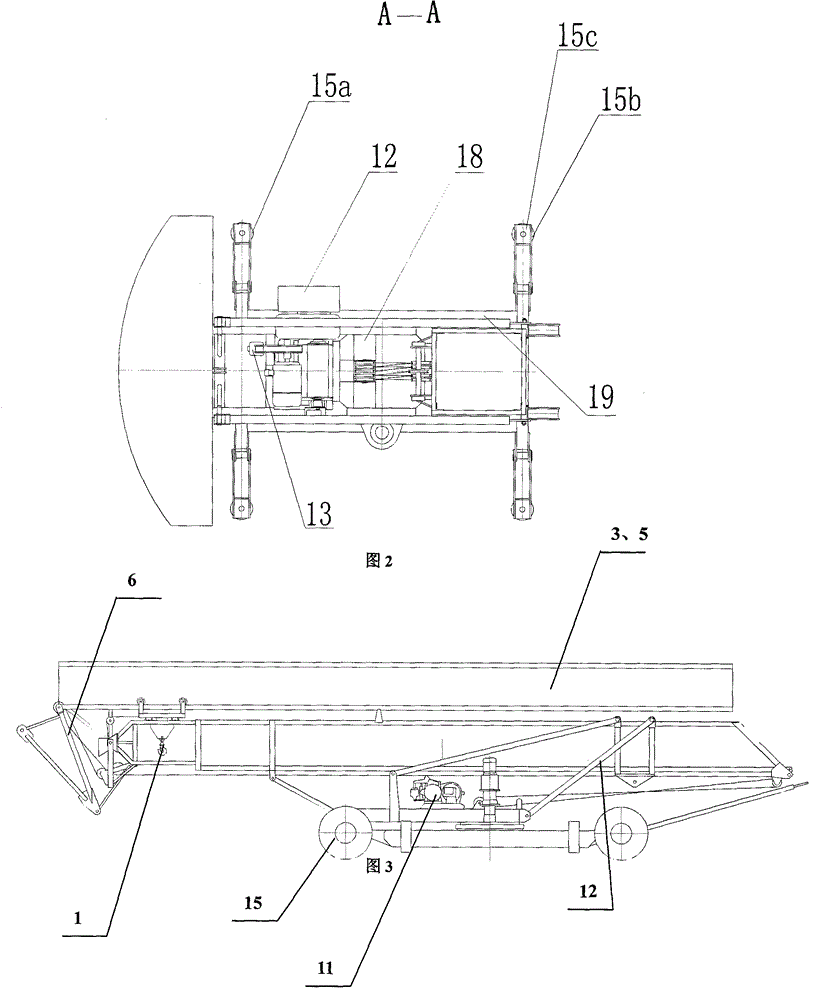

[0015] A quick-loading tower crane, such as figure 1 As shown, it includes hook group 1, luffing trolley 2, luffing mechanism 4, tower body 8, 9, tower arms 3, 5, counterweight 14, electric control cabinet 11, hoisting winch system 13, slewing mechanism 17 , Cable reel 16. The tower body includes an upper tower body 8 and a lower tower body 9. The upper and lower tower bodies are connected by bayonet joints to form a scalable structure. The upper tower body can be compressed to the inside of the lower tower body, and the upper and lower tower bodies are connected by a tail cable system 7 Complete the compression and tension of the tower body. The tower arm includes a front tower arm 3 and a rear tower arm 5. The front and rear tower arms are connected by a pin shaft, and the left and right folding of the tower arm is realized through the arm rope system; the rear end of the rear tower arm 5 is hinged with the tailstock 6, and the tailstock 6 The end point of the tail cable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com