A cantilevered material platform with a lateral support system

A support system and overhanging technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as unexpected shaking, unexpected failure of pre-embedded structures, complex and changeable wind directions, etc., and achieve the effect of reducing unexpected shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

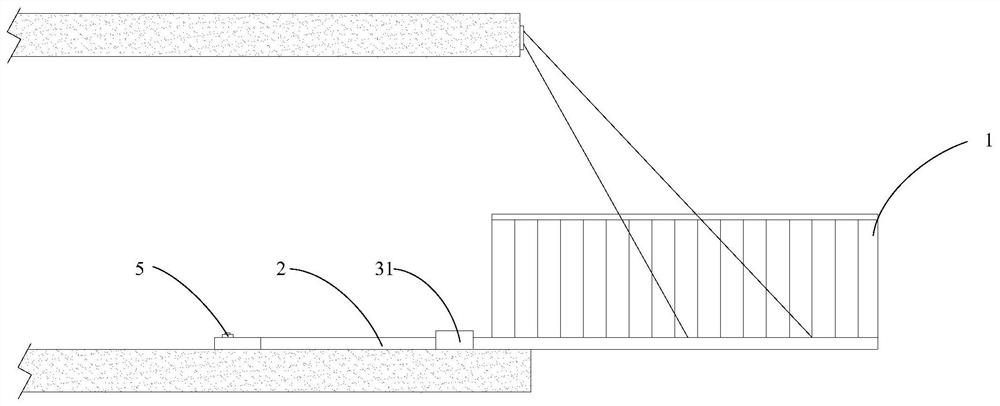

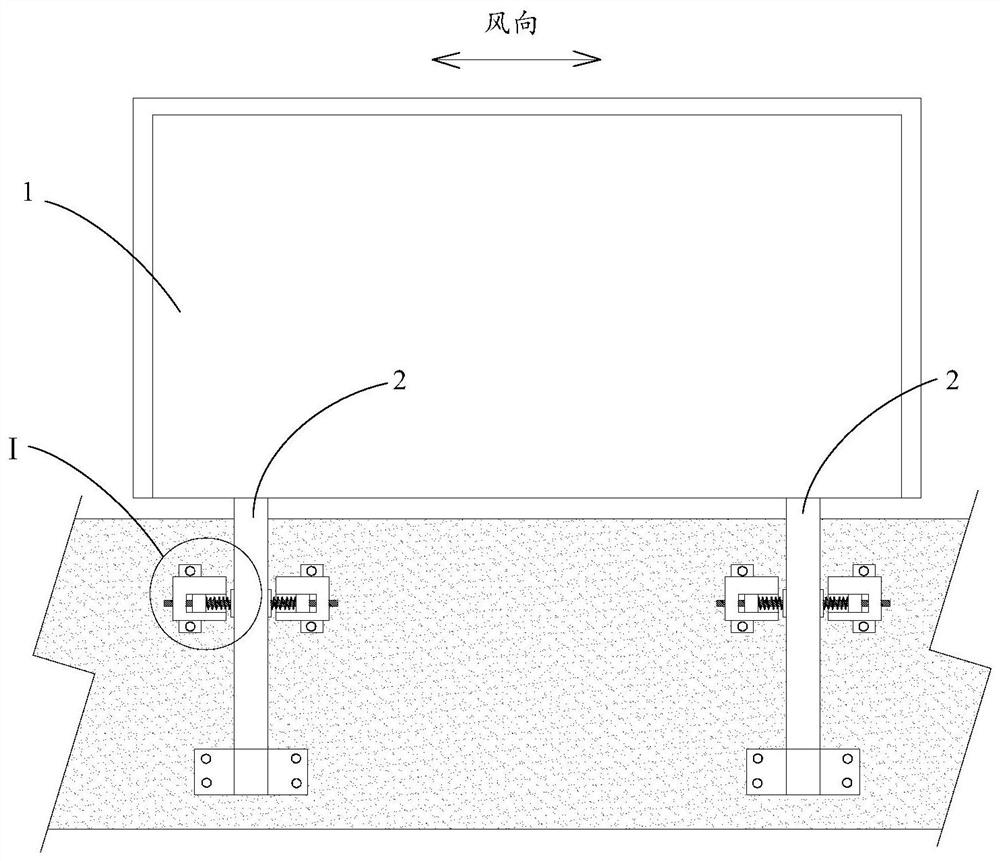

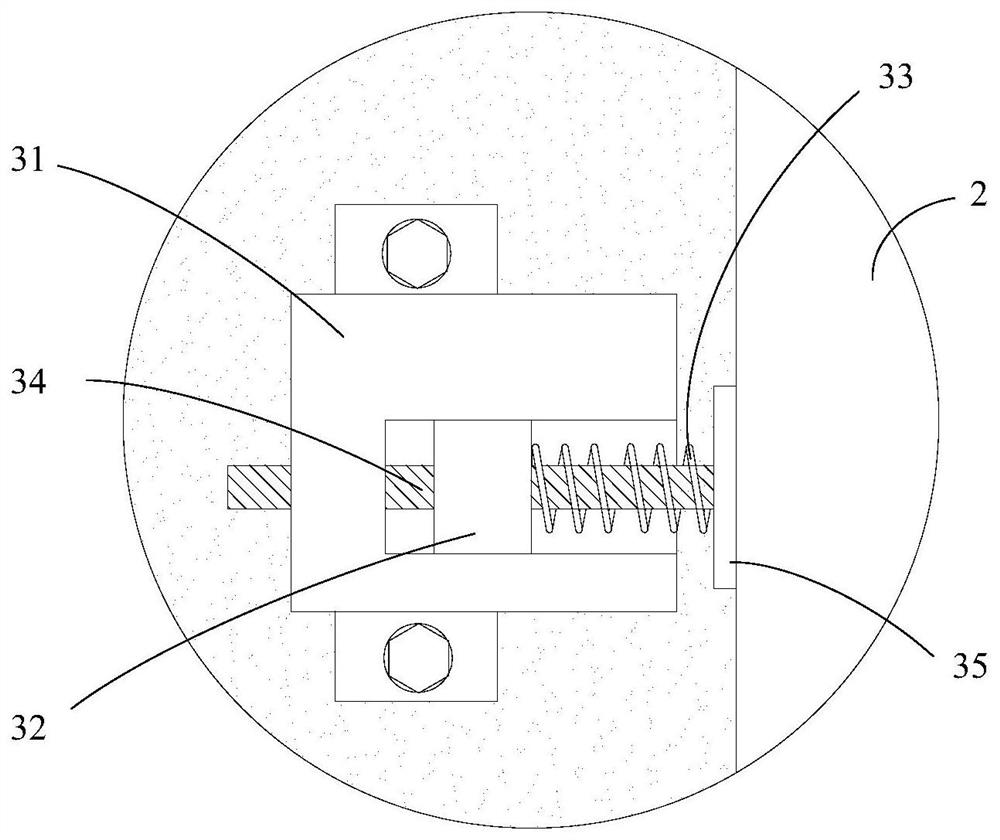

[0034] See figure 1 , figure 2 and image 3 , this embodiment 1 proposes a cantilevered material platform with a lateral support system, including a discharge platform body 1, a cantilevered connecting beam 2, and a lateral supporting system, and the cantilevered connecting beam 2 is fixedly connected to the floor , and the cantilevered connecting beam 2 partially extends outside the floor, the unloading platform body 1 is fixedly connected to the part where the cantilevered connecting beam 2 extends outside the floor, the transverse The supporting system includes two supporting structures placed on the left and right opposite sides of the cantilevered connecting beam 2 , the supporting structures on both sides are fixedly connected to the floor, and clamp the cantilevered connecting beam 2 between them.

[0035] In this embodiment 1, there are two cantilevered connecting beams 2, which are fixedly connected to the floor through the pre-embedded structure 5 embedded in the ...

Embodiment 2

[0053] See Figure 4 , in this embodiment 2, a rigid contact is adopted between the cantilevered connecting beam 2 and the support structure, specifically, the support structure is pre-buried in the floor, and its top protrudes from the floor The pre-embedded rod 4 outside the top surface, the part of the pre-embedded rod 4 protruding from the top surface of the floor is against the cantilevered connecting beam 2, so as to support the cantilevered connecting beam 2 in the left and right direction. Carry out limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com