An assembly line transmission and fixing device for wine box packaging and printing

A packaging printing and fixing device technology, applied in printing devices, general parts of printing machinery, printing and other directions, can solve the problems affecting the printing quality of wine boxes, unstable tension of wine boxes, unfavorable printing of wine boxes, etc. The waiting time for the ink layer to dry, which is beneficial to drying and smooth adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

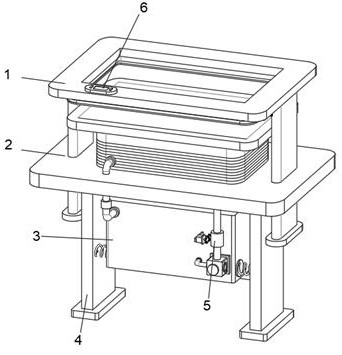

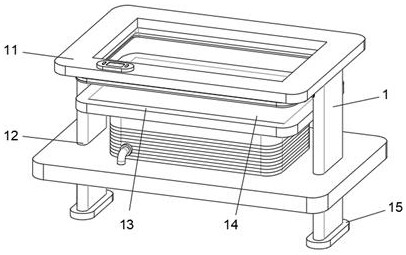

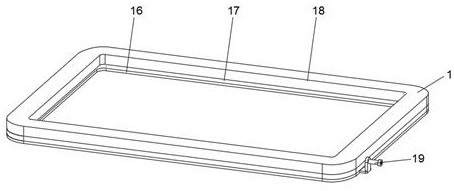

[0029] Please refer to Figure 1 to Figure 9 , an assembly line transmission and fixing device for wine box packaging and printing includes: a mounting plate 2, the lower surface of the mounting plate 2 is fixedly connected with a support leg 4 for connecting with a conveyor belt; a magnetic force fixing mechanism 1, and the magnetic force fixing mechanism 1 and The mounting plate 2 is connected; the supporting mechanism 3 with heating function is connected with the mounting plate 2, and the supporting mechanism 3 with heating function is also connected with the magnetic fixing mechanism 1, and the supporting mechanism 3 with heating function is connected with the magnetic fixing mechanism 1 The supporting mechanism 3 exchanges heat with the magnetic fixing mechanism 1 .

[0030] Need to explain: when the device is in use, the wine box to be printed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com