Display substrate, manufacturing method thereof and display device

A display substrate and pixel definition layer technology, applied to electrical components, electrical solid devices, circuits, etc., can solve the problem of yellowish color of white screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

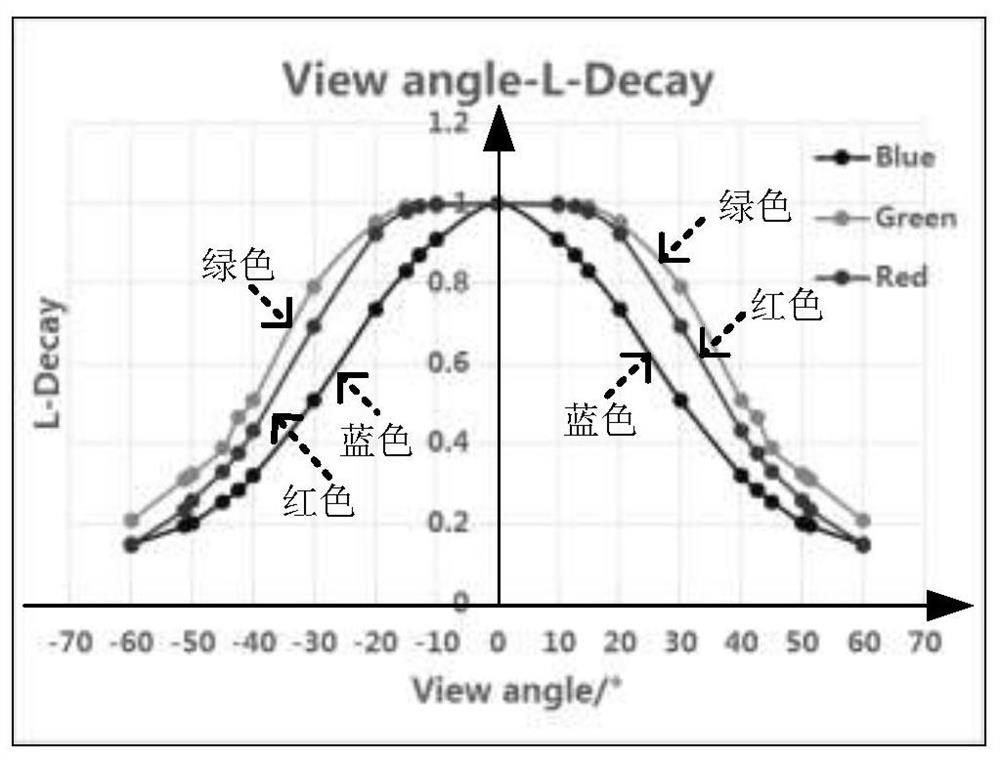

[0055] In recent years, OLED display technology has attracted more attention due to its characteristics of active light emission, high luminous brightness, high resolution, wide viewing angle, fast response speed, low energy consumption and flexibility. In OLED display technology, the yellowish color of white screens under different viewing angles is one of the main reasons restricting the further development of OLED display technology, which seriously affects user experience. The following explains the yellowish color problem of the white screen from the principle:

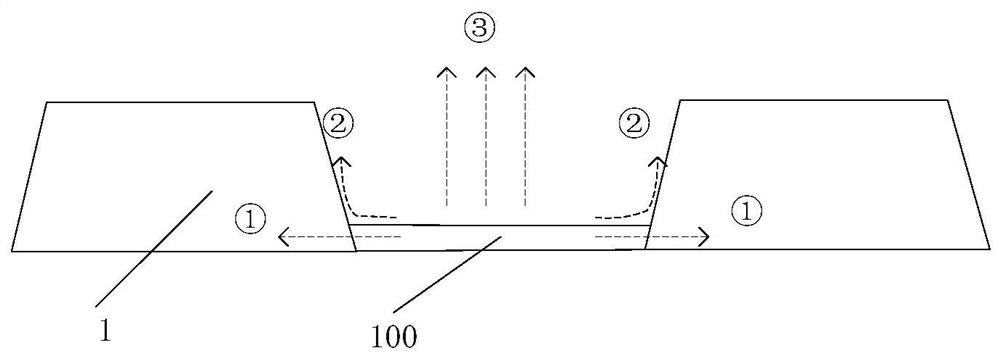

[0056] refer to figure 2 As shown, the light-emitting modes of the OLED light-emitting functional layer 100 can be divided into three types: figure 2 The horizontal light emission along the pixel boundary layer 1 shown in the direction ① in the middle, as shown in figure 2 The light output along the interface between the light-emitting functional layer 100 and the pixel defining layer 1 shown in the directio...

Embodiment 2

[0090] An embodiment of the present invention provides a display device, which includes the display substrate as provided in Embodiment 1.

[0091] The display device may further include a cover plate. The display device is formed after the cover plate is boxed with the above-mentioned display substrate. The display substrate included in the display device is provided with a supporting layer in the first opening of the pixel defining layer, thereby raising the blue light-emitting functional layer, so that the front light emission ratio of the blue light-emitting functional layer is increased, and the lateral light emission ratio is reduced; , the brightness attenuation degree of the blue light emitted by the blue light-emitting functional layer is closer to that of the red light and green light; thus, it can improve the brightness attenuation of the blue light greater than the brightness attenuation of the red light and green light, resulting in a large viewing angle. The ove...

Embodiment 3

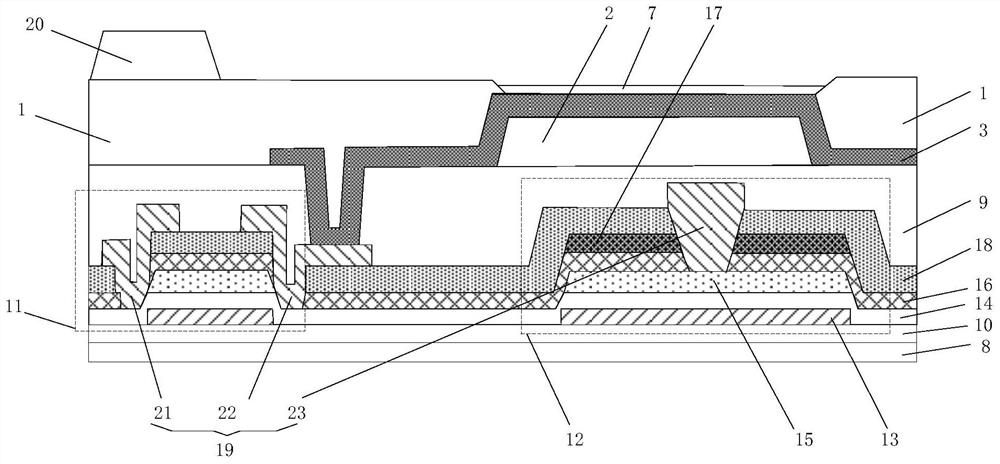

[0094] An embodiment of the present invention provides a method for manufacturing a display substrate as provided in Embodiment 1. The structure of the display substrate can be referred to image 3 As shown, the method includes:

[0095] S01, forming a support layer.

[0096] The above-mentioned supporting layer may be an organic material or an inorganic material other than metal. Exemplarily, the above-mentioned support layer can be made of organic material photoresist, specifically, polyimide photoresist (PI glue) can be used as the photoresist.

[0097] The specific method for forming the support layer is not limited, and may be determined according to actual conditions. For example, the support layer can be formed by inkjet printing process, or the support layer can be formed by coating process.

[0098] S02, forming an anode; Figure 8 As shown, the anode 3 is located on the support layer 2 .

[0099] S03, forming a pixel definition layer (PDL layer).

[0100] The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com