Cable screw connection

A threaded connection and cable technology, applied in the direction of cable entry sealing device, pipe/pipe joint/pipe fitting, pipe support, etc., can solve the problem of difficult axial movement, etc., and achieve the effect of good clamping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

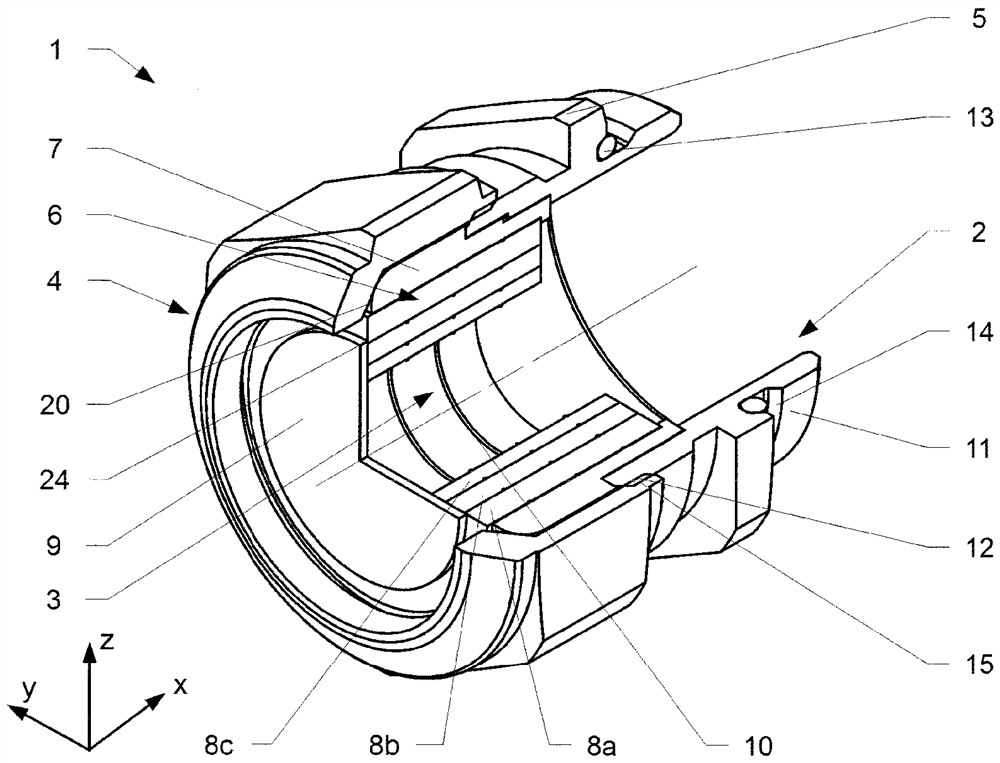

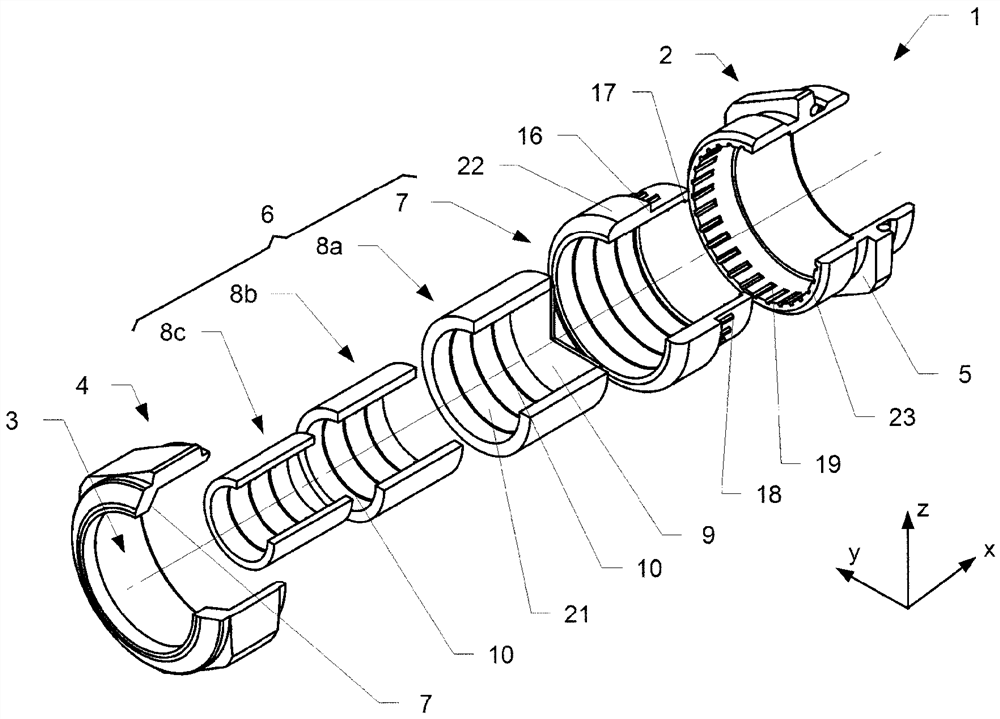

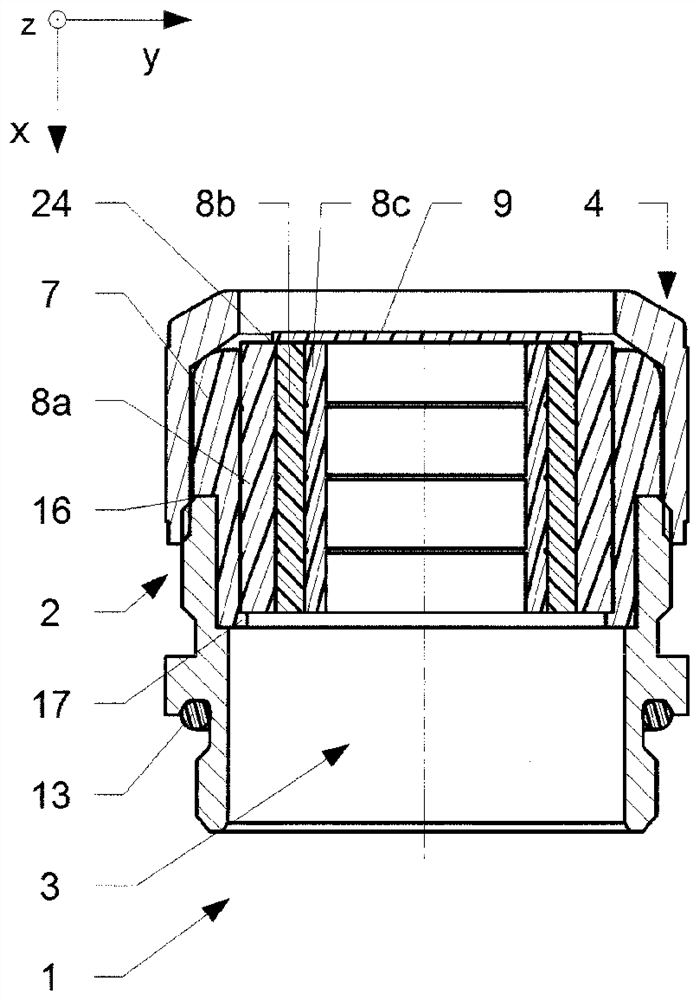

[0022] figure 1 and figure 2 A first variant of the cable screw connection 1 according to the invention is shown in a perspective and partially sectioned view. figure 1 The assembled state of the cable threaded connection 1 is illustrated, while figure 2 The disassembled state is illustrated (exploded view, disassembled in the axial direction). image 3 The same variant of the cable screw connection 1 is shown in a sectional view from the side.

[0023]The cable screw connection 1 has a lead-through opening 3 extending in the axial direction (x-direction) for the lead-through of a cable (not shown in detail). The cable threaded connection part 1 comprises a connecting pipe 2, a clamping nut 4 which can be effectively connected with the connecting pipe 2 in the axial direction (x direction), and one or more pieces arranged internally between the connecting pipe 2 and the clamping nut 4 A one-piece, annular clamping element 6 for clamping the cable in the lead-through open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com