Deep-well pump control method and deep-well pump control device

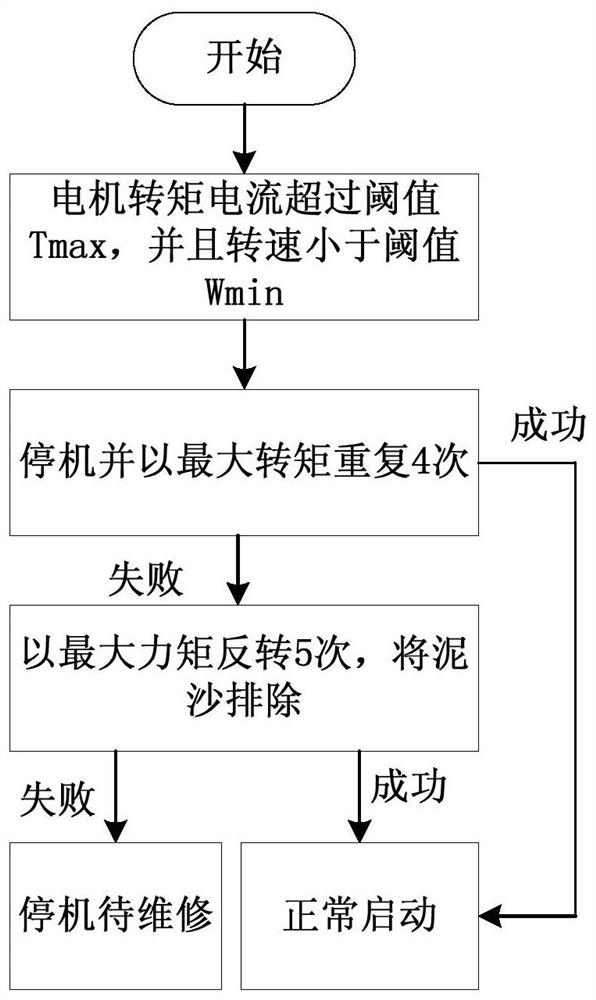

A control method and technology for deep well pumps, applied in pump control, pump devices, pumps, etc., can solve the problems of motor stall, inability to dissipate heat, and inability to start the pump normally, and achieve the effect of solving stalled rotor problems and low implementation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

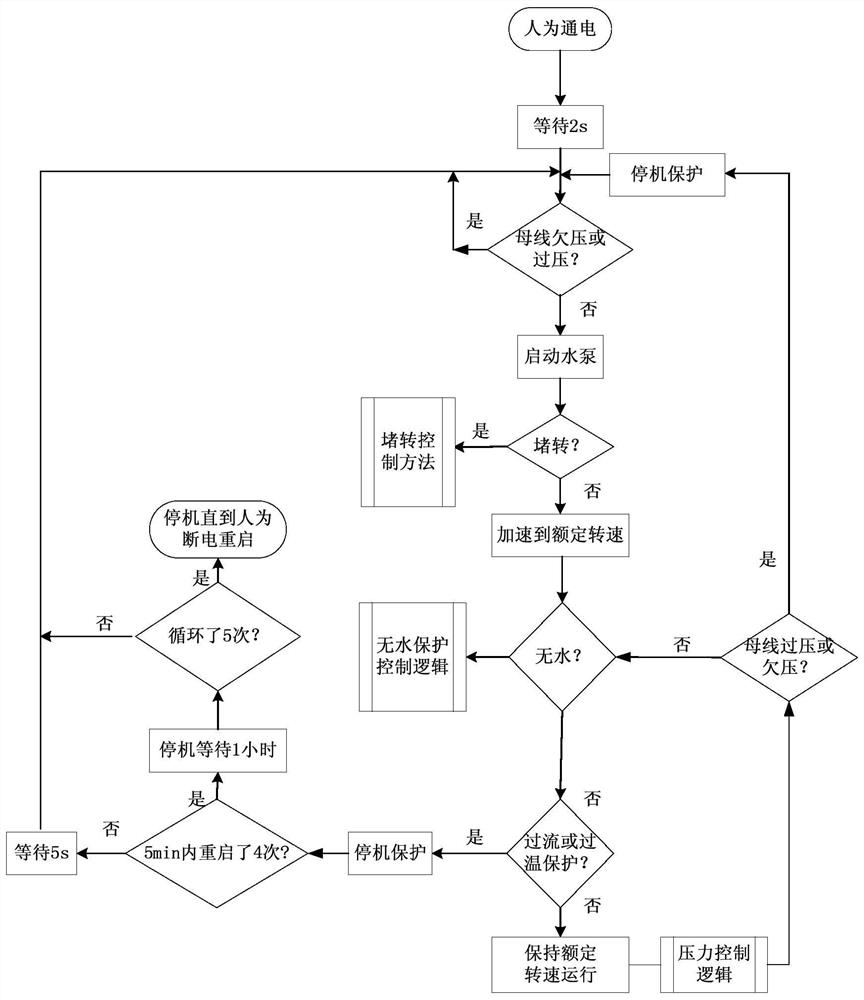

[0029] A deep well pump control method according to an embodiment of the present invention includes the following steps:

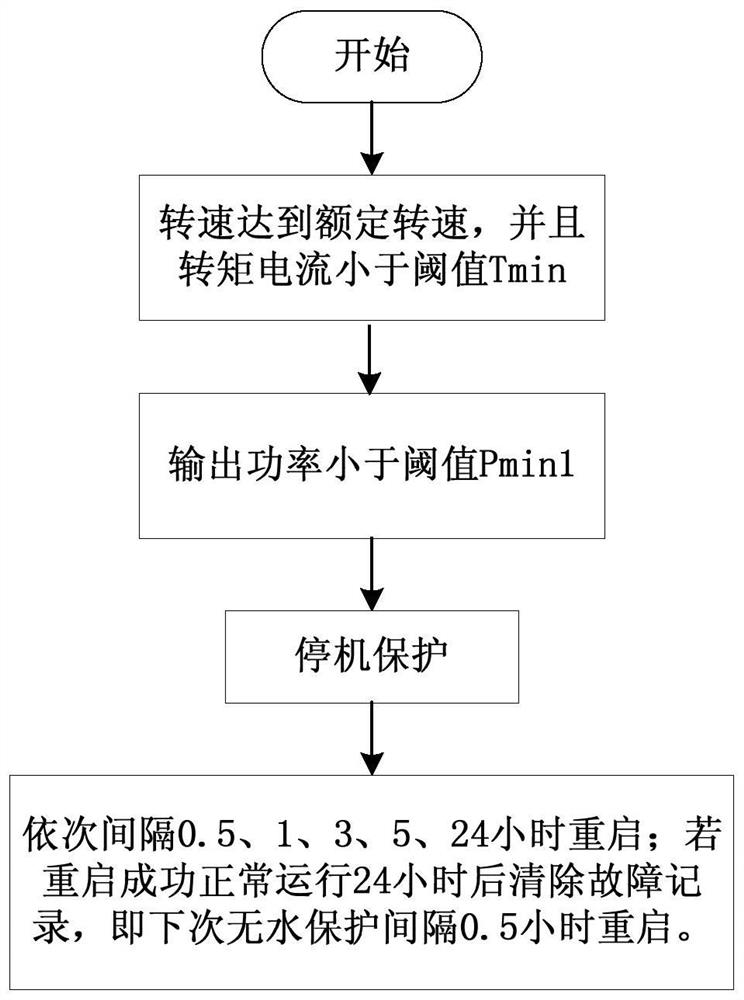

[0030] Control the motor of the deep well pump to run at the rated speed and obtain the torque current and output power of the motor. If the torque current of the motor is less than the predetermined torque current lower limit Tmin, and the output power of the motor is less than the predetermined first power threshold Pmin1, then Control the motor to stop; if the torque current of the motor is greater than or equal to the predetermined torque current lower limit Tmin, and the output power of the motor is greater than or equal to the predetermined first power threshold Pmin1, then perform the next step;

[0031] Judging whether the output power of the motor is less than the predetermined second power threshold Pmin2, if it is greater than or equal to the second power threshold Pmin2, then return to the previous step, and if it is less than the second power t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com