A safe, environment-friendly and pressure-relieving sealing device

An environmentally friendly and pressure relief technology, applied in wellbore/well valve device, sealing/packing, wellbore/well components, etc. To achieve the effect of reduced operating costs, low operating costs, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

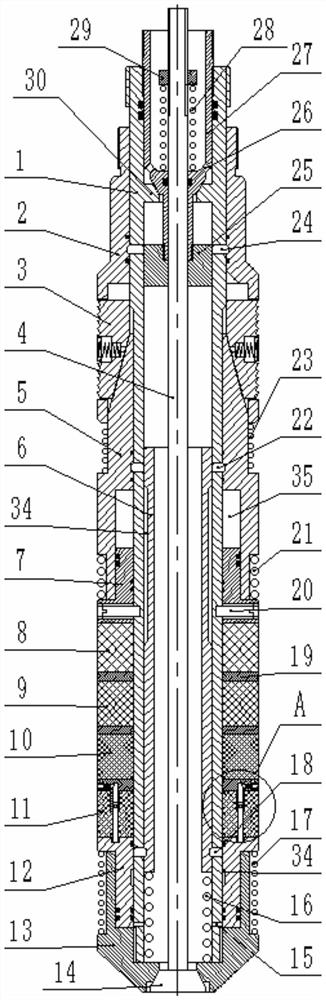

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] Such as figure 1 As shown, the present invention includes a center pipe 1, a slip installation sleeve 2, a slip 3, a cone 5, a rubber sleeve, a setting push sleeve 12 and a piston sleeve 13, a slip installation sleeve 2, a cone 5, a rubber sleeve and The setting push sleeves 12 are all set on the central pipe 1 , and the slips 3 are installed around the central pipe 1 through the slip installation sleeve 2 . The above structure is a common structure in the prior art, and will not be repeated here.

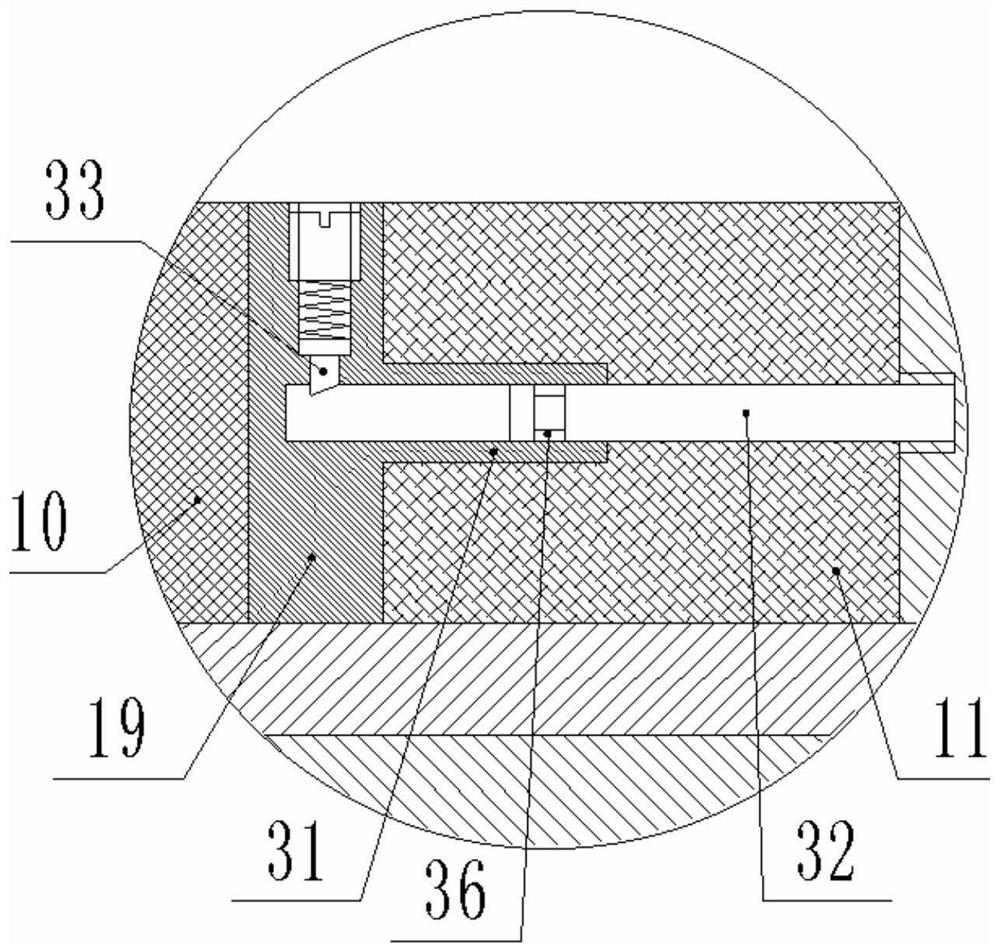

[0031] One of the major innovations of the present invention is that there are four rubber cartridges in total, which are respectively called rubber cartridge A8, rubber cartridge B9, rubber cartridge C10 and rubber cartridge D11, and the four rubber cartridges are arranged in the central tube 1 from top to bottom. The hardness of the rubber tubes on the outer side decr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com